Description

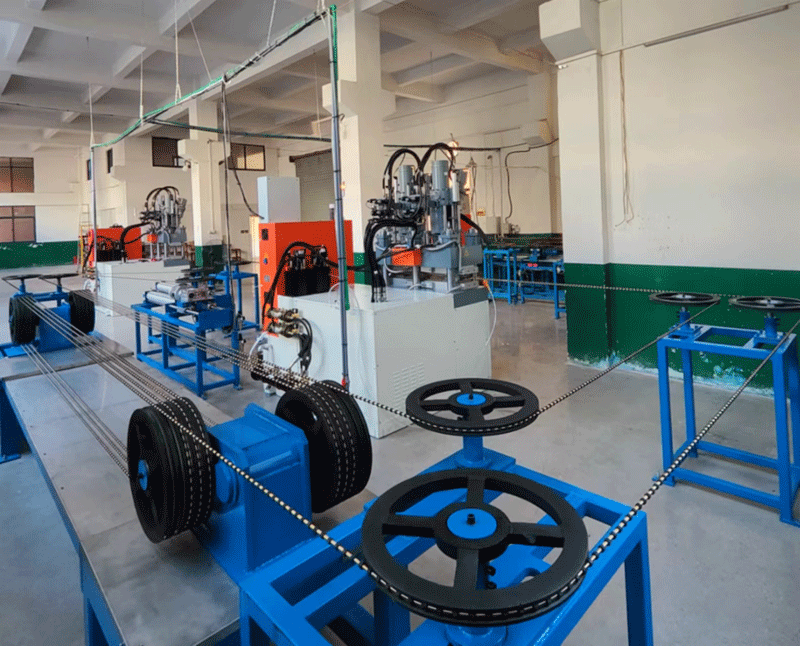

GOWIN are providing turn-key solutions for Diamond Wire Saw Production including moulding machine, rubber mold, tension machine, factory layout suggestion, Rubber Material, Production Training etc, GOWIN supply the one-stop buying&whole-line service lifetime support! GOWIN insist in dedicating to help customers to save the cost and provide the quality turkey solution for diamond wire saw production!

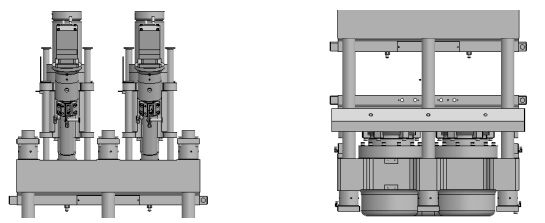

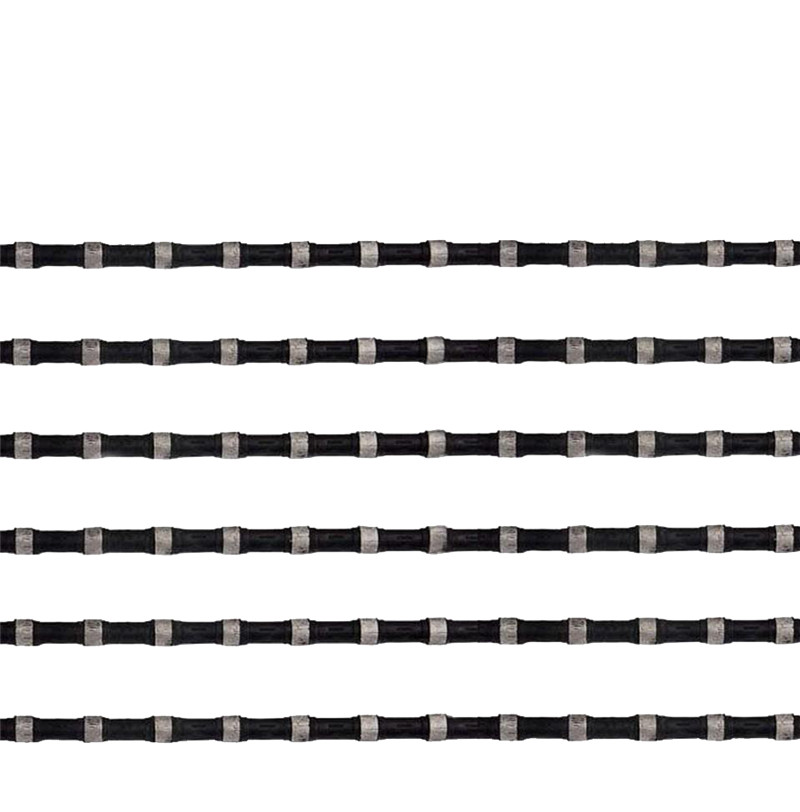

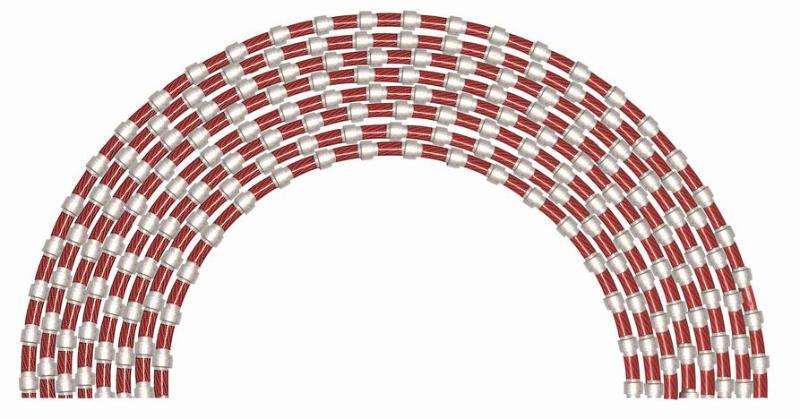

GOWIN Specialized design vertical molding machine is an ideal choice for making Diamond Wire Saw, the design with high injection pressure and secure the bonding between diamond beads and steel wires, and it equips with multiple auxiliaries equipment interfaces, it is the most suitable rubber machine for producing the diamond wire saw! And it earns very good repute from customers in the field of Diamond Tools. Rubber Diamond Wire Saw made by GOWIN Oil Press machine are having good performance both for quarry and concrete!

GOWIN with over 16 years sufficient experience in the field of Diamond Wire Saw Production line, GOWIN has exported many Molding Machines for making the diamond wire saw to many countries such Korea, Russia, India, Egypt, Ukraine, Indonesia, Thailand, Malaysia, Vietnam and China domestic market etc.

Welcome to send enquiry to GOWIN, let’s GO and win-win!

Rubber Injection Machine Main Specification

|

Model |

GW-D280L |

GW-D400L |

|

Clamping Force(KN) |

2800 |

4000 |

|

Mold Open Stroke(mm) |

200 |

200 |

|

Platen Size(mm) |

230x1100 |

230x1100 |

|

Injection Volume(c.c) |

155x2 |

155x2 |

|

Injection Force(bar) |

2150 |

2150 |

Packing & Shipping

|

Container |

GW-D280L |

GW-D400L |

|

20GP |

1 unit |

1 unit |

|

40HQ |

3 units |

3 units |

|

Packing |

Package 1: Vertical Rubber Injection Molding Machine Main Body |

|

|

Package 2: Vertical Rubber Injection Machine Injection Unit |

||

Main Features

● Specialized rubber injection machine for making Rubber Diamond Wire Saw.

● Double injection system, reduce runner and improve molding quality

● Double clamping system, enhance overall mechanical strength,bigger clamping force ensure better bonding between diamond beads and steel wires.

● High injection pressure, secure the bonding between diamond beads and steel wires.

● Applicable for multi-cavity mold, high production efficiency.

● Using the control system and servo motor pump from vertical injection moulding machine,high control accuracy, low energy consumption and low noise.

● Multiple auxiliary equipment interface, Well-equipped functions.

● Especially designed downward clamping structure, the molding cavities distribute at the external side of tie bar with uniform force, ideal for molding circular TPU diamond wire saw.