Our benefits are decrease charges,dynamic income group,specialised QC,solid factories,top quality products and services for Supply OEM Hot Selling! Rubber Product Making Vulcanizing Press Compression Molding Machine with CE ISO9001, We welcome clients, enterprise associations and mates from all parts in the world to speak to us and search for cooperation for mutual positive aspects.

Our benefits are decrease charges,dynamic income group,specialised QC,solid factories,top quality products and services for Frame Flat Vulcanizer and Plate Press Vulcanizer, Since always, we adhering to the “open and fair, share to get, the pursuit of excellence, and creation of value”values, adhere to the”integrity and efficient, trade-oriented, best way , best valve” business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

Main Features

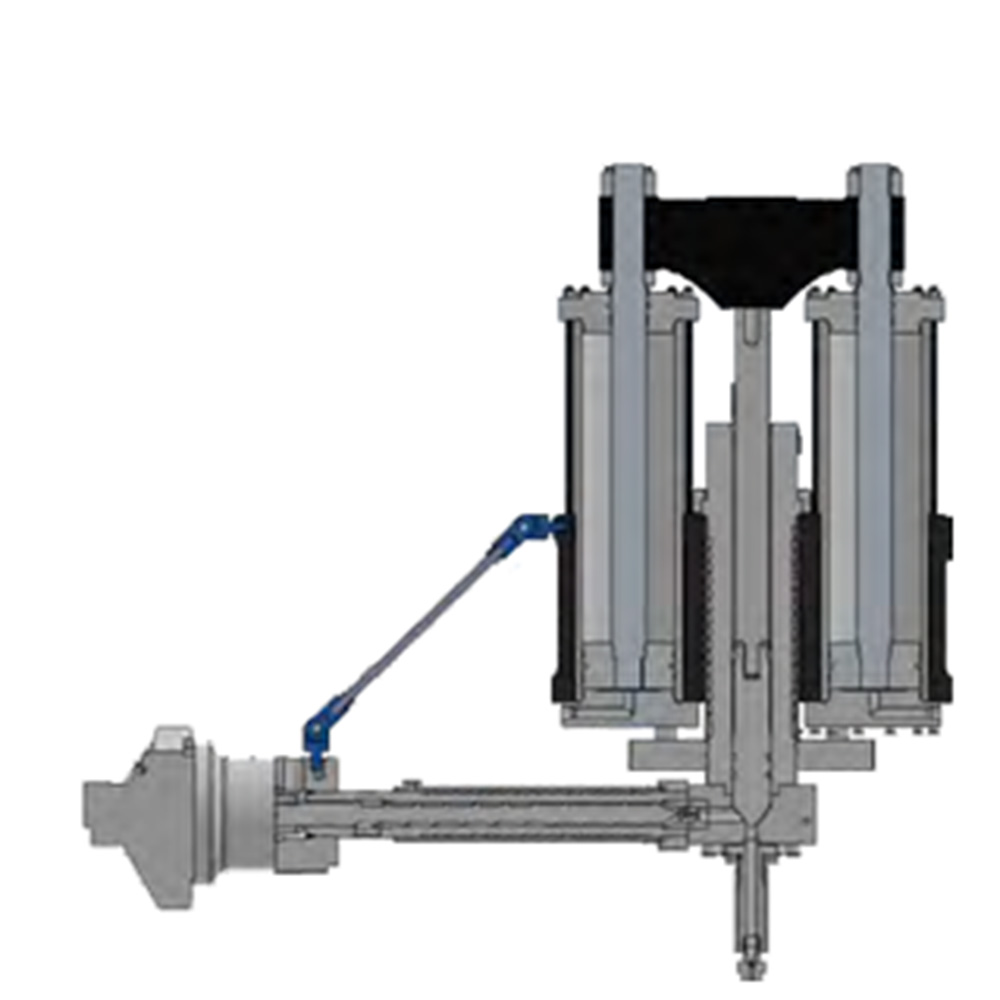

GW-RL Series Vertical Rubber Injection Machine are the most hot-selling & widely used GOWIN Rubber Injection Molding Machine models. The machines are equipped with VERTICAL CLAMPING SYSTEM & F.I.L.O. VERTICAL INJECTION SYSTEM, suitable for most rubber molded products in the fields of automobile, energy, railway transportation, industry, medical care and household appliances etc. And the Rubber Molding Machine is suitable for various of rubber compounds such as NR, NBR, EPDM, SBR, HNBR, FKM, SILICONE, ACM, AEM, etc.

The Rubber Molding Machine greatly improves production efficiency and reduces labor costs compared to traditional compression presses. It is an idea of Rubber Moulding Machine Models involving automation / semi-automation rubber molding. Also, the Rubber Machine is available for HOT RUNNER MOLD & COLD RUNNER BLOCK SYSTEM MOLD (optional solutions for CRB mold).

We GOWIN are expert for rubber machinery & rubber moulding solutions. Do not hesitate to contact us.

GW-RL Main Specification

|

Model |

GW-R120L |

GW-R160L |

GW-R250L |

GW-R300L |

GW-R350L |

GW-R400L |

|||||

|

Clamping Force(KN) |

1200 |

1600 |

2500 |

3000 |

3500 |

4000 |

|||||

|

Mold Open Stroke(mm) |

450 |

500 |

500 |

500 |

500 |

600 |

|||||

|

Platen Size(mm) |

430×500 |

500×500 |

560×630 |

600×700/600×800 |

700×800 |

700×800 |

|||||

|

Injection Volume(c.c) |

1000 |

1000 |

1000 |

2000 |

3000 |

3000 |

5000 |

3000 |

5000 |

5000 |

8000 |

|

Injection Force(bar) |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

| Model | GW-R550L | GW-R650L | GW-R800L | GW-R1200L | ||||

| Clamping Force(KN) | 5500 | 6500 | 8000 | 12000 | ||||

| Mold Open Stroke(mm) | 600 | 700 | 700 | 800 | ||||

| Platen Size(mm) | 850×1000 | 950×1000 | 950×1000 | 1200×1300 | ||||

| Injection Volume(c.c) | 5000 | 8000 | 5000 | 8000 | 8000 | 12000 | 12000 | 15000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

Packing & Shipping

|

Container |

GW-R120L |

GW-R160L |

GW-R250L |

GW-R300L |

GW-R400L |

|

20GP |

1 unit |

1 unit |

1 unit |

– |

- |

|

40HQ |

3 units |

3 units |

2 units |

2 units |

2 units |

|

Packing |

Package 1: Rubber Injection Machine Main Body |

||||

|

Package 2: Rubber Injection Machine Injection Unit |

|||||

|

Container |

GW-R550L |

GW-R650L |

GW-R800L |

GW-R1200L |

|

20GP |

– |

– |

– |

1 unit (one 40HQ + one 20GP) |

|

40HQ |

1 unit |

1 unit |

1 unit |

|

|

Packing |

Package 1: Vertical Rubber Injection Moulding Machine Main Body |

|||

|

Package 2: Vertical Rubber Injection Moulding Machine Injection Unit |

||||

Main Features

● Fixed-cylinder Vertical Injection

● High-pressure & High-precision Injection

● Modular-design & Multiple-combinations Solutions

● Low- bed & Optimized Structure

● Humanized Operating System

● High-efficiency & High-stability Hydraulic System

Injection System

● F.I.L.O. Injection System, low rubber feeding height.

● Two-Fixed Cylinder for injection, steady injection and high injection accuracy & stability

● Injection Unit center of gravity in bottom which lead to more steady operation.

● Excellent Oil Cooling System for SCREW & BARREL ensuring WHOLE RUBBER CHANCEL under accuracy temperature control to get better fluency of rubber compound.

● Injection Unit available to move up & down, more convenient for daily operation and maintenance.

Our benefits are decrease charges,dynamic income group,specialised QC,solid factories,top quality products and services for Supply OEM Hot Selling! Rubber Product Making Vulcanizing Press Compression Molding Machine with CE ISO9001, We welcome clients, enterprise associations and mates from all parts in the world to speak to us and search for cooperation for mutual positive aspects.

Supply OEM Frame Flat Vulcanizer and Plate Press Vulcanizer, Since always, we adhering to the “open and fair, share to get, the pursuit of excellence, and creation of value”values, adhere to the”integrity and efficient, trade-oriented, best way , best valve” business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.