Description

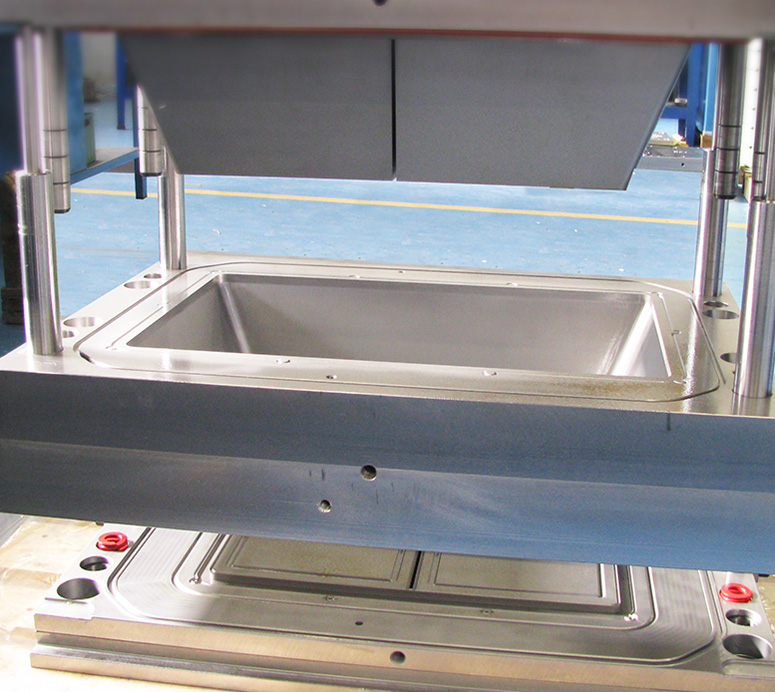

Compression Moulding Press is one of the most common & traditional machine presses using in the filed of press moulding rubber. It is a kind of mainly manual press machine. The press moulding machine is more suitable for small rubber products with large quantity molding cavity or huge net compound volume of rubber moulding & silicone rubber molding.

It is also a good choice for customers who having small demand of some rubber molded products or starting new business of rubber molding due to lower investment of the rubber press & simple rubber moulding process rather than injection moulding process. Beside, the compression press is available for transfer molding also which could have better quality control for some critical rubber molded components need similar process of vertical injection molding machine.

GOWIN are providing high-end vulcanizing press which apply same high performance component as rubber injection machine to ensure same user experience from GOWIN.

GW-Compression Molding Machine

|

Model |

GW-P200D |

GW-P250D |

GW-P300D |

|

Clamping Force(KN) |

2000 |

2500 |

3000 |

|

Mold Open Stroke(mm) |

250 |

250 |

300 |

|

Platen Size(mm) |

550x550 |

650x600 |

650x650 |

Packing & Shipping

|

Container |

GW-P200D |

GW-P250D |

GW-P300D |

|

20GP |

1 unit |

1 unit |

1 unit |

|

40HQ |

3 units |

3 units |

2 units |

|

Packing |

Package 1: Rubber Vulcanizing Machine Main Body |

||

|

Package 2: Vulcanizing Machine Guarding & Auxiliary |

|||

Main Features

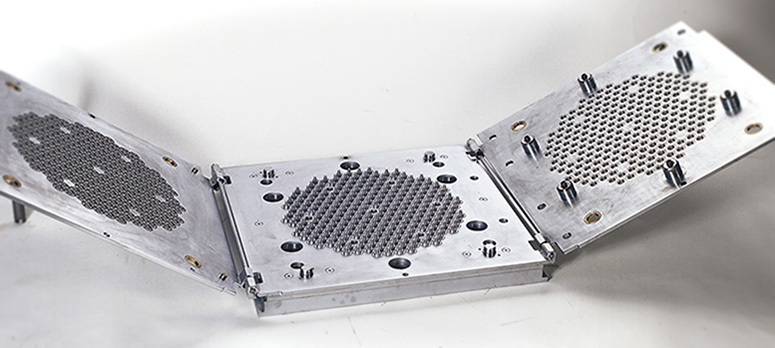

● Double Independent Hydraulic System, Double Stations Working Independently.

● Strong Enough Machine Design

● Humanized Design, Easy Operation & Convenient Maintenance.

● Multiple-combinations Optional Device.