Our workforce through experienced training. Skilled expert knowledge, potent sense of assistance, to satisfy the service demands of customers for Renewable Design for Compression Molding Rubber Machine Hydraulic Silicone Rubber Plate O Ring Vulcanizing Hot Press Machine, Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

Our workforce through experienced training. Skilled expert knowledge, potent sense of assistance, to satisfy the service demands of customers for Vulcanizing Machine and Hydraulic Vulcanizing Hot Press Machine, When you are keen on any of our goods following you view our product list, be sure to feel free to make contact with us for inquiries. You’ll be able to send us emails and get in touch with us for consultation and we shall respond to you as soon as we’re able to. If it’s convenient, you could find out our address in our web site and come to our enterprise. or additional information of our products by yourself. We’re generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.

Description

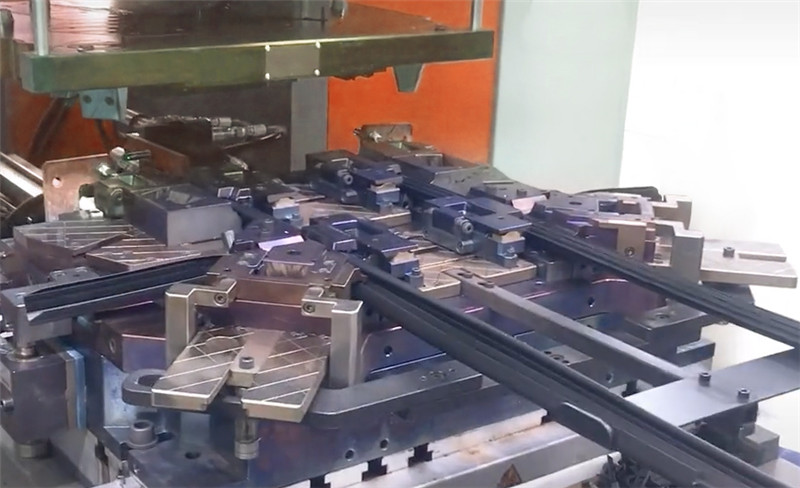

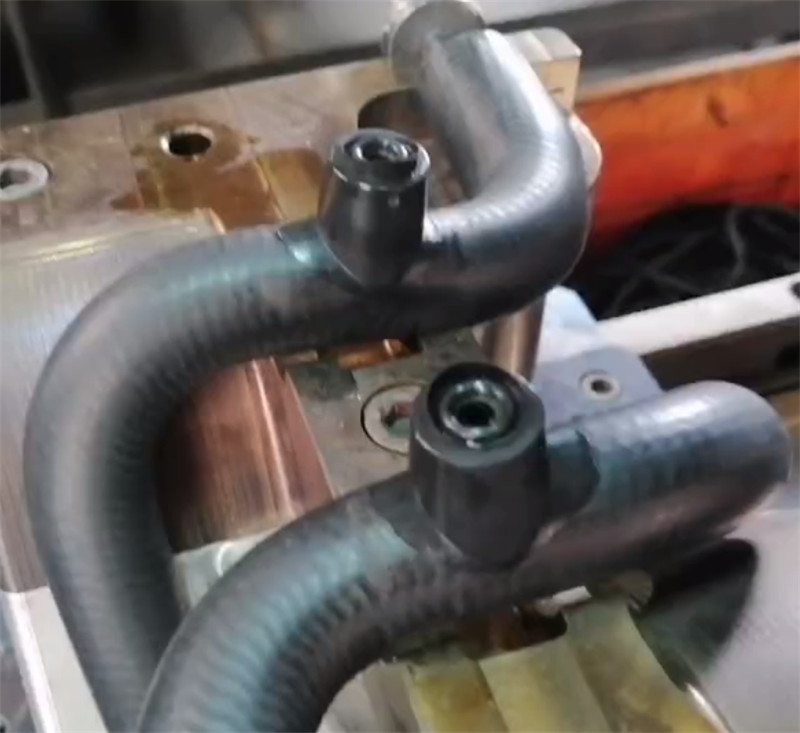

The C-frame Series Rubber Injection Machine is a special design injection molding machine for car-sealing Joint rubber molding. Due to Three-Side Access for Operation, these moulding press models are also suitable for some precision rubber moulded components such as oil seal etc. With an Optional Injection Unit, the molding machine is available for various materials such as RUBBER / PLASTIC / LSR. With a High-precision Injection System and High-efficiency, High-stability & Energy-saving SERVO SYSTEM, the C-Frame Rubber Injection Moulding Machine greatly improves production efficiency and reduces labor costs and achieving high quality rubber moulding.

C-Frame Main Specification

| Model | GW-C30L | GW-C50L | GW-C80L | |||

| GW-C30F | GW-C50F | GW-C80F | ||||

| Clamping Force(KN) | 300 | 500 | 800 | |||

| Mold Open Stroke(mm) | 300 | 460 | 460 | |||

| Platen Size(mm) | 400×300 | 500×400 | 600×500 | |||

| Injection Volume(c.c) | 50 | 160 | 50 | 160 | 160 | 350 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

Packing & Shipping

| Container | GW-C30L | GW-C50L | GW-C80L |

| GW-C30F | GW-C50F | GW-C80F | |

| 20GP | 2 unit | 2 unit | 2 unit |

| 40HQ | 4 units | 4 units | 3 units |

| Packing | Package 1: Rubber Injection Moulding Machine Main Body; | ||

| Package 2: Rubber Injection Moulding Machine Injection Uni | |||

Main Features

● C-Frame Clamping Unit, Available for operation in 3 Sides.

● Precise Injection.

● High-efficiency, High-stability & Energy saving Servo Hydraulic System.

● Modular-design & Multiple-combinations Solution to Meet Customer’s Various Demand.

● Double Stations

● Optional Injection Units for Three Types of Material: Rubber/Plastic/LSR

Our workforce through experienced training. Skilled expert knowledge, potent sense of assistance, to satisfy the service demands of customers for Renewable Design for Compression Molding Rubber Machine Hydraulic Silicone Rubber Plate O Ring Vulcanizing Hot Press Machine, Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

Renewable Design for Vulcanizing Machine and Hydraulic Vulcanizing Hot Press Machine, When you are keen on any of our goods following you view our product list, be sure to feel free to make contact with us for inquiries. You’ll be able to send us emails and get in touch with us for consultation and we shall respond to you as soon as we’re able to. If it’s convenient, you could find out our address in our web site and come to our enterprise. or additional information of our products by yourself. We’re generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.