We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Reasonable price for Customized Plastic Injection Molding Solution, We welcome prospects, organization associations and close friends from all pieces with the globe to get in touch with us and look for cooperation for mutual gains.

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of China Customized Plastic Injection Molding and Injection Molding for ABS Material, Now we have more than 10 years experience of production and export business. We always develop and design kinds of novel solutions to meet the market demand and help the guests continuously by updating our products. We’ve been specialized manufacturer and exporter in China. Wherever you are, be sure to join us, and together we will shape a bright future in your business field!

Description

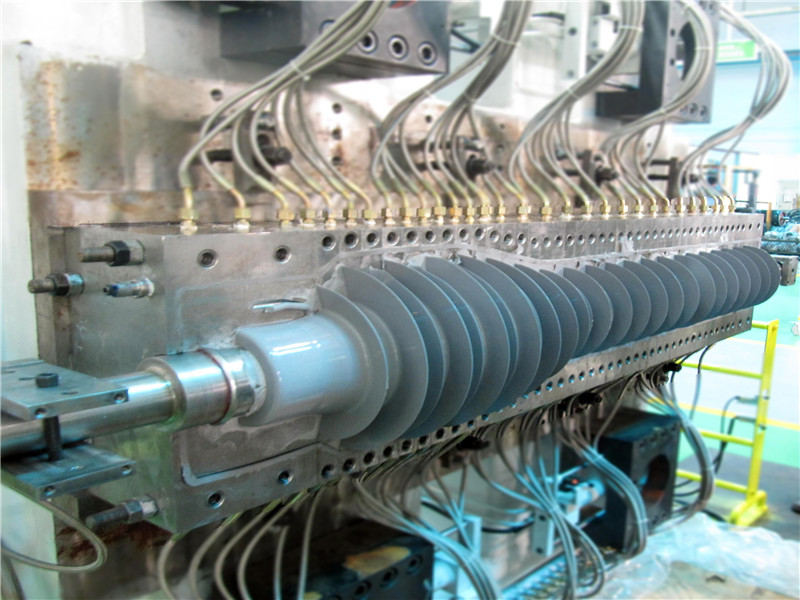

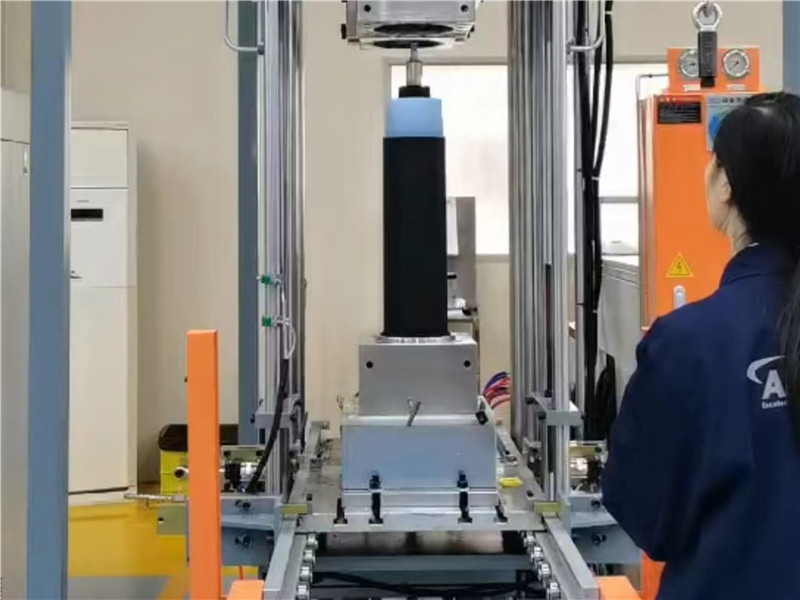

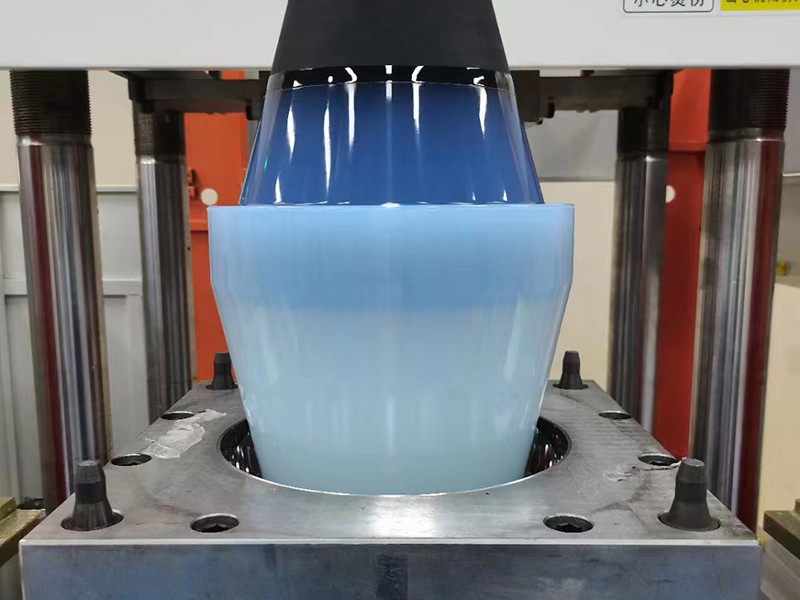

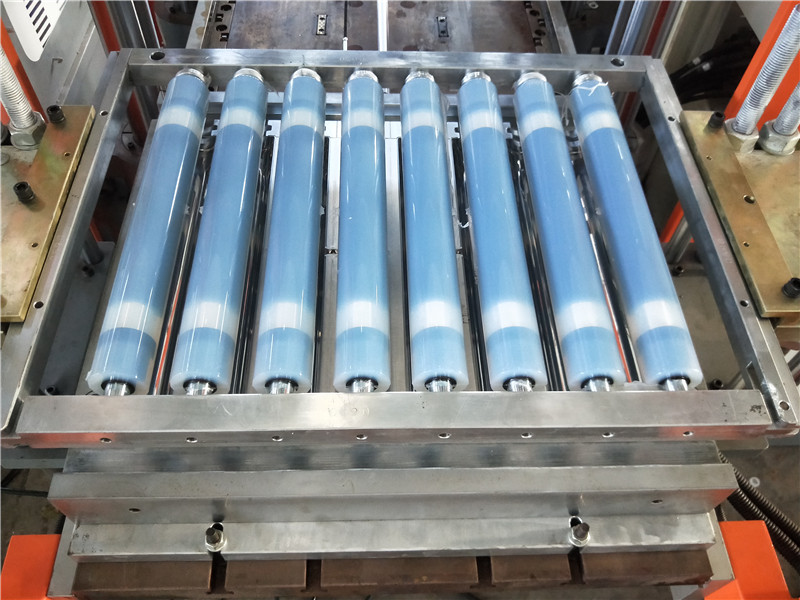

GOWIN provide various High-efficiency, High-stability & Energy-saving molding solutions for LSR Cable Accessories Industry. Many solutions are the FIRST in the industry and customers could flexibly select different equipment combinations according to different characteristics of various types of products & molding process requirements, which greatly enhance customer competitive strength and user experience. We are an excellent rubber moulding solutions provider and providing different types of LSR Clamping Machine.

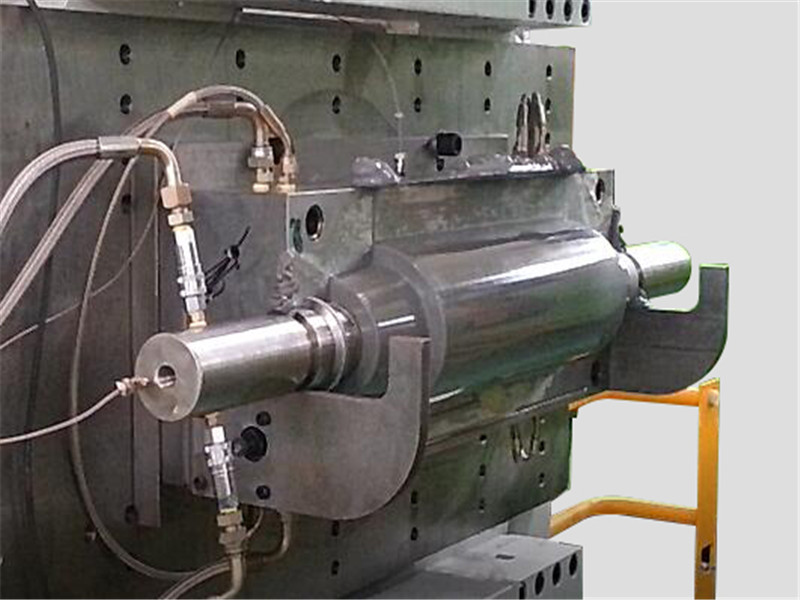

GOWIN LSR Mold Clamping Molding Machine is specialized design model for Liquid Silicone Rubber Molding especially for producing cable accessories such as CABLE TERMINATION, MID-JOINT, DEFLECTOR etc.

With over 16 years sufficient experience in the field of power transmission & distribution, GOWIN has exported mass of Cable Accessories Making Machine to many countries and domestic market. GOWIN are providing turn-key solutions for silicone injection molding including factory layout suggestion, silicone moulding machine, LSR Mold, LSR Dosing Machine, Electrical Testing Equipment, Material, Production Training etc.,the buyer could enjoy the one-stop buying to save much time&energy&cost,the most important is acquired the most professional service to make new project successful quickly.

![]()

LSR Molding Machine Main Specification

|

Model |

GW-H160 |

GW-H250 |

GW-P120 |

GW-P250 |

GW-P400 |

GW-P300 |

|

Clamping Unit |

Horizontal |

Horizontal |

Vertical |

Vertical |

Vertical |

Vertical |

|

Mold Open Direction |

Right to Left |

Right to Left |

Bottom to Top |

Bottom to Top |

Bottom to Top |

Top to Bottom |

|

Clamping Force (KN) |

1600 |

2500 |

1200 |

2500 |

4000 |

3000 |

|

Mold Opens Stroke(mm) |

1000 |

1400 |

600/1100/1300 |

1100/1300 |

1100/1300 |

500 |

|

Plates Size(mm) |

900×1400 |

900×1800 |

550×550 |

700×700 |

750×800 |

750×800 |

Packing & Shipping

|

Container |

GW-H160 |

GW-H250 |

GW-P120 |

GW-P250 |

GW-P400 |

GW-P300 |

|

20GP |

- |

- |

1 unit |

1 unit |

1 unit |

- |

|

40HQ |

2 units |

2 units |

2 units |

2 units |

2 units |

3 units |

|

Packing |

Package 1: Rubber Injection Machine Main Body |

|||||

|

Package 2: Rubber Injection Machine Clamping Unit |

||||||

|

Package 3: Rubber Injection Machine Guarding & Auxiliary |

||||||

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Reasonable price for Customized Plastic Injection Molding Solution, We welcome prospects, organization associations and close friends from all pieces with the globe to get in touch with us and look for cooperation for mutual gains.

Reasonable price for China Customized Plastic Injection Molding and Injection Molding for ABS Material, Now we have more than 10 years experience of production and export business. We always develop and design kinds of novel solutions to meet the market demand and help the guests continuously by updating our products. We’ve been specialized manufacturer and exporter in China. Wherever you are, be sure to join us, and together we will shape a bright future in your business field!

-

Hot Sale for Nylon Rope Rubber Plastic Single F...

-

Dealers of Silicone Automatic Speed Pneumatic V...

-

Top Grade New Technology for Making Pipe Fittin...

-

PriceList for Silicone Molds for Concrete Makin...

-

ODM Factory Newest Type High Pressure Polyureth...

-

High reputation Automotive Parts Grille Injecti...