We take “customer-friendly, quality-oriented, integrative, innovative” as objectives. “Truth and honesty” is our management ideal for Professional Design Jm-1200II Electric Plastic Injection Molding Machine Small Vertical Plastic Injection Molding Machine for Making Toys, We play a leading role in delivering shoppers with premium quality goods great assistance and competitive rates.

We take “customer-friendly, quality-oriented, integrative, innovative” as objectives. “Truth and honesty” is our management ideal for Plastic Injection Molding Machine and Injection Molding Machine, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

Description

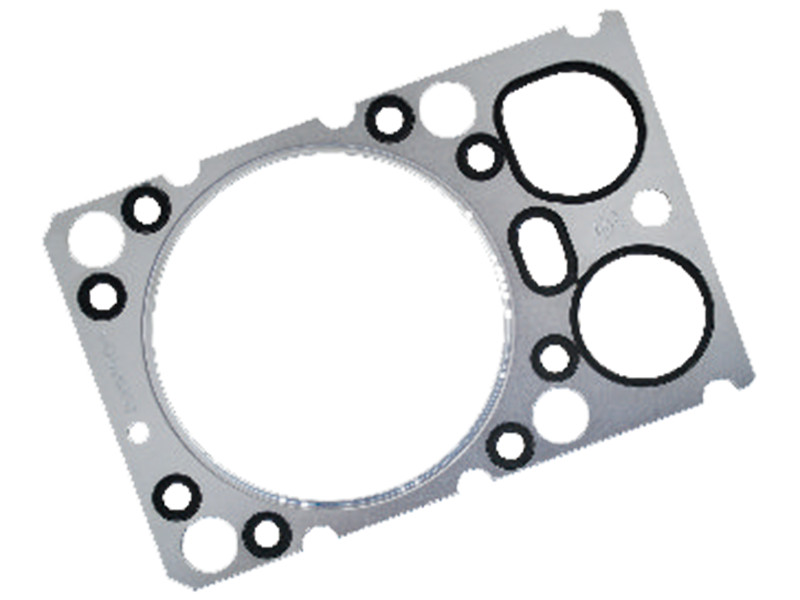

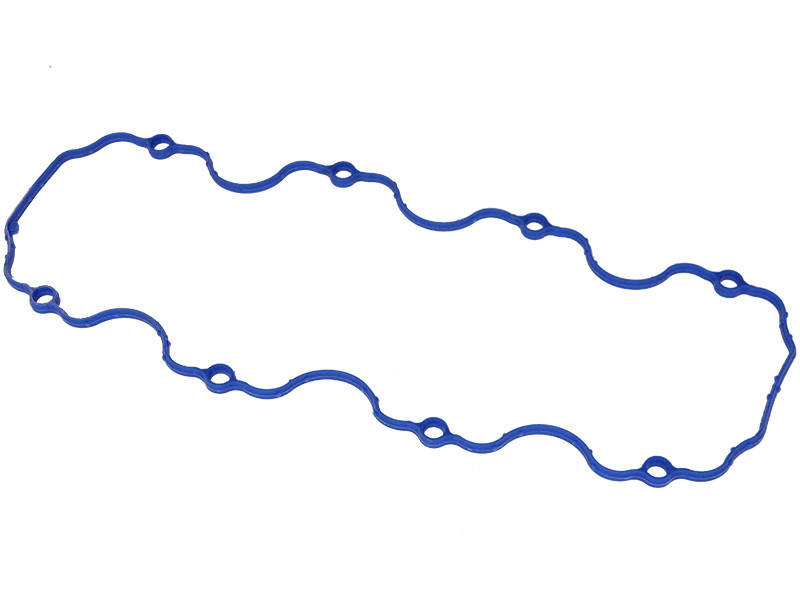

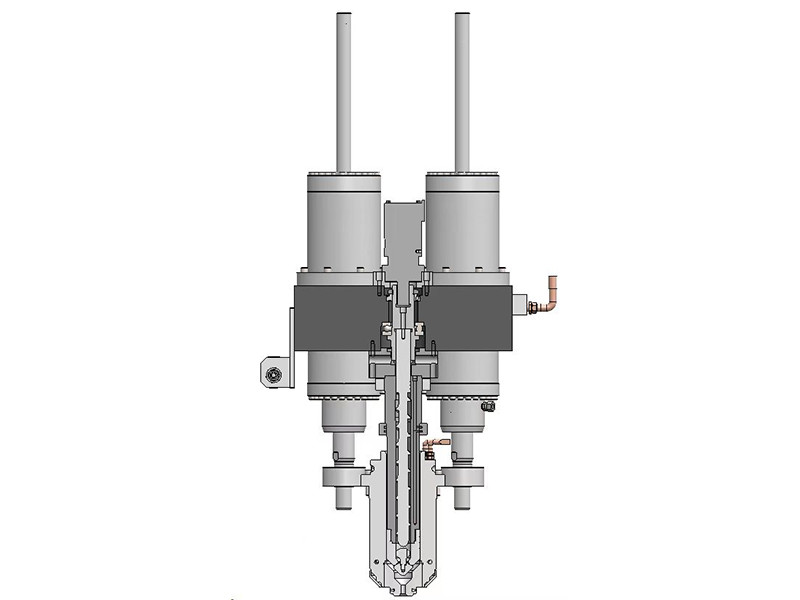

The GW-RF Series F.I.F.O Vertical Rubber Injection Moulding Machine are GOWIN High-End Rubber Moulding Machine Models. The machines are equipped with a VERTICAL CLAMPING SYSTEM & F.I.F.O. VERTICAL INJECTION SYSTEM, suitable for various rubber molded parts, especially precision rubber sealing products in the field of automobile, energy, railway transportation, industry, medical care and household appliances, etc.

With the High performance of the F.I.F.O. Injection System, the Rubber Moulding Machine is available to match all kinds of rubber moulding such as NR, NBR, EPDM, SBR, HNBR, FKM, SILICONE, ACM, AEM, etc.

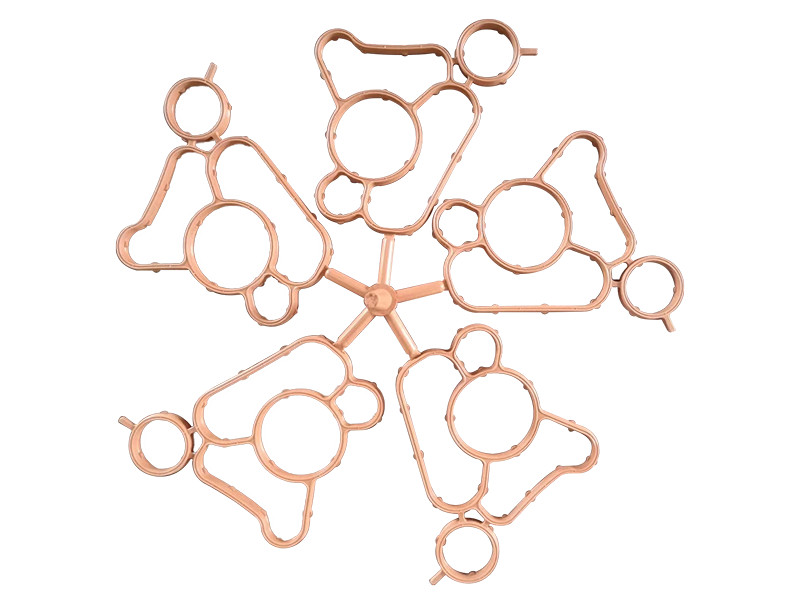

With High-end SERVO SYSTEM, the Rubber Molding Machine is greatly improving production efficiency and reducing labor costs. It is an idea of Rubber Molding Machine Models involving automation rubber molding. Also, the Rubber Machine is available for HOT RUNNER MOLD & COLD RUNNER BLOCK SYSTEM MOLD (optional solutions for CRB mold).

GW-RF Main Specification

| Model | GW-R120F | GW-R160F | GW-R250F | GW-R300F | ||||

| Clamping Force(KN) | 1200 | 1600 | 2500 | 3000 | ||||

| Mold Open Stroke(mm) | 450 | 500 | 500 | 500 | ||||

| Platen Size(mm) | 430×500 | 500×500 | 560×630 | 600×700/600×800 | ||||

| Injection Volume(c.c) | 1000 | 1000 | 500 | 1000 | 2000 | 500 | 1000 | 2000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

| Model | GW-R400F | GW-R550F | GW-R650F | ||||||

| Clamping Force(KN) | 4000 | 5500 | 6500 | ||||||

| Mold Open Stroke(mm) | 600 | 600 | 700 | ||||||

| Platen Size(mm) | 700×800 | 850×1000 | 950×1000 | ||||||

| Injection Volume(c.c) | 1000 | 2000 | 3000 | 1000 | 2000 | 3000 | 1000 | 2000 | 3000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

Packing & Shipping

|

Container |

GW-R120F |

GW-R160F |

GW-R250F |

|

20GP |

1 unit |

1 unit |

1 unit |

|

40HQ |

3 units |

3 units |

2 units |

|

Packing |

Package 1: Rubber Machine Main Body; |

||

|

Package 2: Rubber Machine Injection Unit |

|||

|

Container |

GW-R550F |

GW-R650F |

|

20GP |

– |

– |

|

40HQ |

1 unit |

1 unit |

|

Packing |

Package 1: Molding Machine Main Body; |

|

|

Package 2: Molding Machine Injection Unit |

||

Main Features

● Precise Injection

● Modular-design & Multiple-combinations Solutions

● Low-bed & Optimized Structure

● Humanized Operating System

● High-efficiency &High-stability& High-Energy-Saving Servo Hydraulic System

Injection System

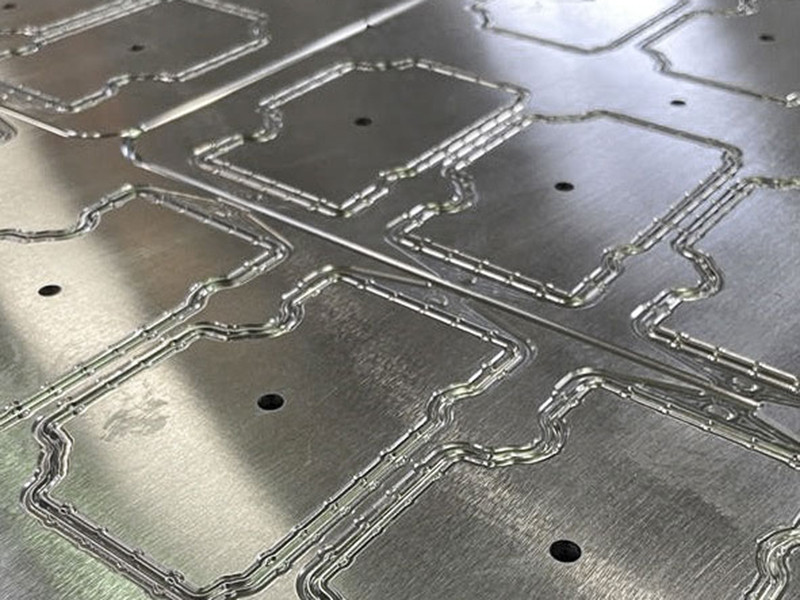

● F.I.F.O. Injection System, Moving-Cylinder Vertical Injection

● High-speed & High-pressure & High-precision Injection

● Short Injection Nozzle Design, Less injection pressure loss

● Available for Various Special Rubber Compound Such as VITON

We take “customer-friendly, quality-oriented, integrative, innovative” as objectives. “Truth and honesty” is our management ideal for Professional Design Jm-1200II Electric Plastic Injection Molding Machine Small Vertical Plastic Injection Molding Machine for Making Toys, We play a leading role in delivering shoppers with premium quality goods great assistance and competitive rates.

Professional Design Plastic Injection Molding Machine and Injection Molding Machine, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.