Excellent comes 1st; service is foremost; small business is cooperation” is our organization philosophy which is regularly observed and pursued by our company for One of Hottest for Rubber Injection Molding Machinery with Vacuum Chamber, Our highly specialized process eliminates the component failure and offers our customers unvarying quality, allowing us to control cost, plan capacity and maintain consistent on time delivery.

Excellent comes 1st; service is foremost; small business is cooperation” is our organization philosophy which is regularly observed and pursued by our company for China Rubber Injection Molding Machine and Injection Molding Machinery, Our solutions have enjoyed a great reputation for their good quality, competitive prices and prompt shipment in international market. Presently, we’ve been sincerely looking forward to cooperating with more overseas customers based on mutual benefits.

Description

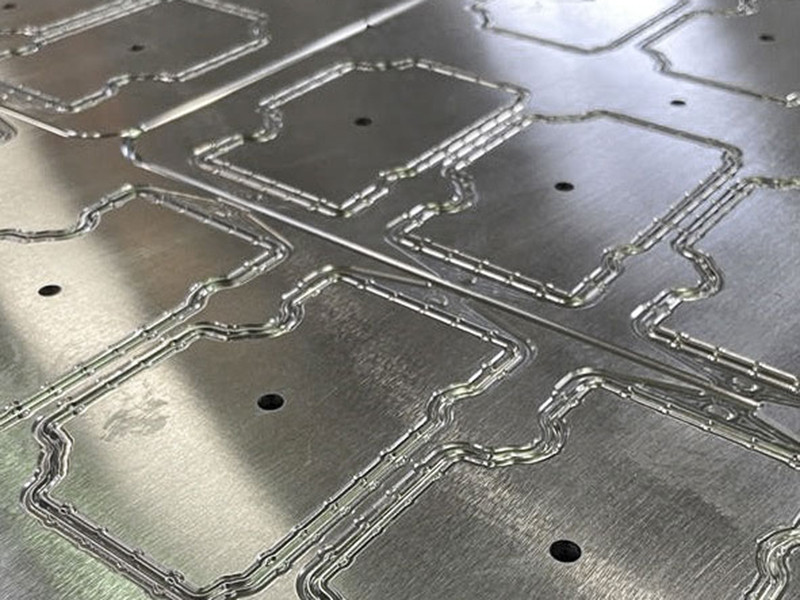

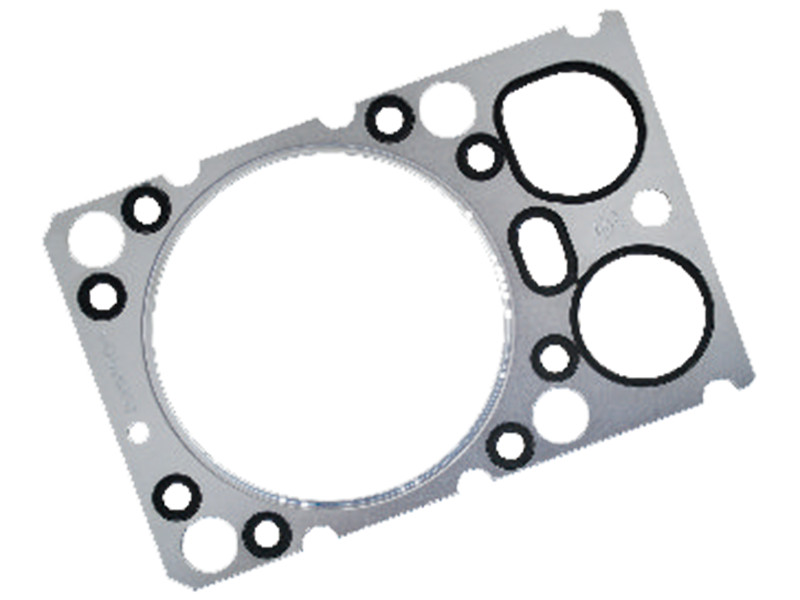

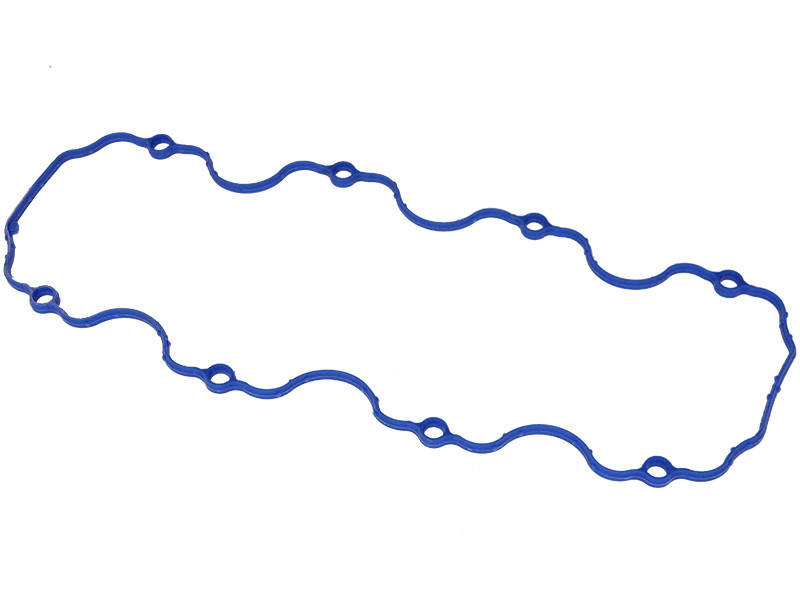

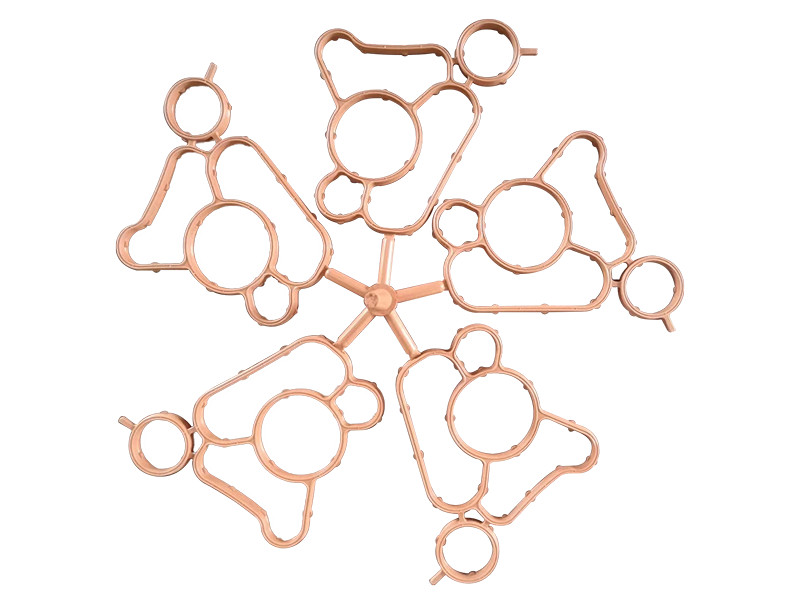

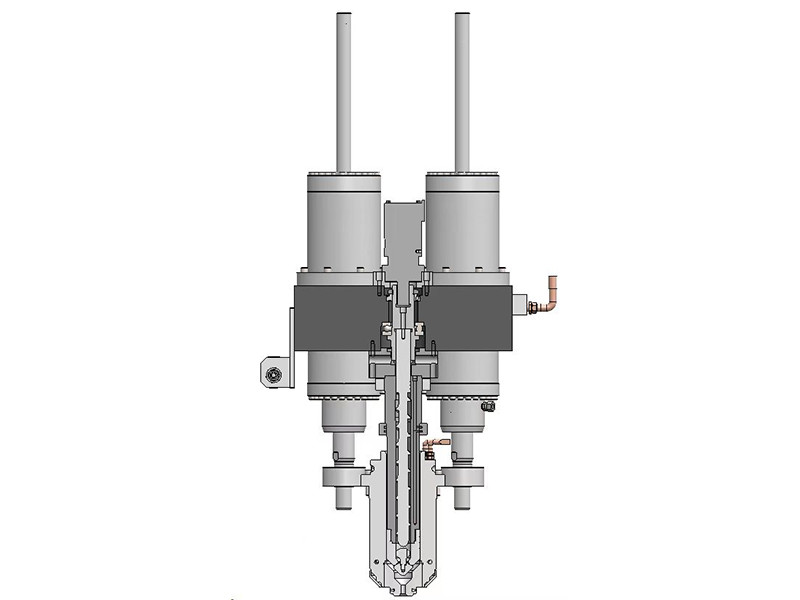

The GW-RF Series F.I.F.O Vertical Rubber Injection Moulding Machine are GOWIN High-End Rubber Moulding Machine Models. The machines are equipped with a VERTICAL CLAMPING SYSTEM & F.I.F.O. VERTICAL INJECTION SYSTEM, suitable for various rubber molded parts, especially precision rubber sealing products in the field of automobile, energy, railway transportation, industry, medical care and household appliances, etc.

With the High performance of the F.I.F.O. Injection System, the Rubber Moulding Machine is available to match all kinds of rubber moulding such as NR, NBR, EPDM, SBR, HNBR, FKM, SILICONE, ACM, AEM, etc.

With High-end SERVO SYSTEM, the Rubber Molding Machine is greatly improving production efficiency and reducing labor costs. It is an idea of Rubber Molding Machine Models involving automation rubber molding. Also, the Rubber Machine is available for HOT RUNNER MOLD & COLD RUNNER BLOCK SYSTEM MOLD (optional solutions for CRB mold).

GW-RF Main Specification

| Model | GW-R120F | GW-R160F | GW-R250F | GW-R300F | ||||

| Clamping Force(KN) | 1200 | 1600 | 2500 | 3000 | ||||

| Mold Open Stroke(mm) | 450 | 500 | 500 | 500 | ||||

| Platen Size(mm) | 430×500 | 500×500 | 560×630 | 600×700/600×800 | ||||

| Injection Volume(c.c) | 1000 | 1000 | 500 | 1000 | 2000 | 500 | 1000 | 2000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

| Model | GW-R400F | GW-R550F | GW-R650F | ||||||

| Clamping Force(KN) | 4000 | 5500 | 6500 | ||||||

| Mold Open Stroke(mm) | 600 | 600 | 700 | ||||||

| Platen Size(mm) | 700×800 | 850×1000 | 950×1000 | ||||||

| Injection Volume(c.c) | 1000 | 2000 | 3000 | 1000 | 2000 | 3000 | 1000 | 2000 | 3000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

Packing & Shipping

|

Container |

GW-R120F |

GW-R160F |

GW-R250F |

|

20GP |

1 unit |

1 unit |

1 unit |

|

40HQ |

3 units |

3 units |

2 units |

|

Packing |

Package 1: Rubber Machine Main Body; |

||

|

Package 2: Rubber Machine Injection Unit |

|||

|

Container |

GW-R550F |

GW-R650F |

|

20GP |

– |

– |

|

40HQ |

1 unit |

1 unit |

|

Packing |

Package 1: Molding Machine Main Body; |

|

|

Package 2: Molding Machine Injection Unit |

||

Main Features

● Precise Injection

● Modular-design & Multiple-combinations Solutions

● Low-bed & Optimized Structure

● Humanized Operating System

● High-efficiency &High-stability& High-Energy-Saving Servo Hydraulic System

Injection System

● F.I.F.O. Injection System, Moving-Cylinder Vertical Injection

● High-speed & High-pressure & High-precision Injection

● Short Injection Nozzle Design, Less injection pressure loss

● Available for Various Special Rubber Compound Such as VITON

Excellent comes 1st; service is foremost; small business is cooperation” is our organization philosophy which is regularly observed and pursued by our company for One of Hottest for Rubber Injection Molding Machinery with Vacuum Chamber, Our highly specialized process eliminates the component failure and offers our customers unvarying quality, allowing us to control cost, plan capacity and maintain consistent on time delivery.

One of Hottest for China Rubber Injection Molding Machine and Injection Molding Machinery, Our solutions have enjoyed a great reputation for their good quality, competitive prices and prompt shipment in international market. Presently, we’ve been sincerely looking forward to cooperating with more overseas customers based on mutual benefits.

-

Discount wholesale Customized Frame Type Rubber...

-

OEM/ODM Manufacturer Custom Thermoset Piece Sil...

-

Hot sale Jaw Structure and Pillar Structure Min...

-

High reputation Rubber Vacuum Moulding Machine ...

-

Horizontal Injection Moulding Machine for Silic...

-

OEM Customized Polyurethane/ Phenolic Continuou...