It adheres on the tenet “Honest, industrious, enterprising, innovative” to acquire new solutions regularly. It regards shoppers, success as its very own success. Let us establish prosperous future hand in hand for OEM Customized Wholesale Industrial Rotary Vane Vacuum Pump for Vacuum Metallurgy, We welcome new and aged prospects from all walks of existence to speak to us for potential company associations and mutual success!

It adheres on the tenet “Honest, industrious, enterprising, innovative” to acquire new solutions regularly. It regards shoppers, success as its very own success. Let us establish prosperous future hand in hand for China Rotary Vane Vacuum Pump and Vacuum Pump, As operation principle is “be market-oriented , good faith as principle, win-win as objective”, holding on “customer first, quality assurance, service first” as our purpose, dedicated to provide the original quality, create excellence service , we won the praise and trust in the industry of auto parts. In the future, We will provide quality product and excellent service in return to our customers , welcome any suggestions and feedback from all over the world.

Description

The GW-SL Series Rubber Injection Molding Machine with VERTICAL CLAMPING SYSTEM & F.I.L.O. Angle-Type INJECTION SYSTEM is one of the MOST POPULAR Rubber Molding Machine in the market. The Moulding Press Single-Fixed-Cylinder Injection Unit, horizontally mounting on the top platen which reduces overall rubber Press height a lot. This rubber press model is suitable for customers who have limited-height workshops.

Also, the Rubber Molding Machine is suitable for most rubber molded products in the fields of automobile, energy, railway transportation, industry, medical care and household appliances, etc. The Molding Machine is suitable for various rubber compounds such as NR, NBR, EPDM, SBR, HNBR, FKM, SILICONE, ACM, AEM, etc.

The Rubber Injection Moulding Machine greatly improves production efficiency and reduces labor costs compared with traditional compression press.

GW-SL Main Specification

| Model | GW-S120L | GW-S160L | GW-S250L | GW-S300L | GW-S400L | ||||

| Clamping Force(KN) | 1200 | 1600 | 2500 | 3000 | 4000 | ||||

| Mold Open Stroke(mm) | 450 | 500 | 500 | 500 | 600 | ||||

| Platen Size(mm) | 430×500 | 500×500 | 560×630 | 600×700/600×800 | 700×800 | ||||

| Injection Volume(c.c) | 1000 | 1000 | 1000 | 2000 | 3000 | 3000 | 5000 | 5000 | 8000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

| Model | GW-S550L | GW-S650L | GW-S800L | GW-S1200L | ||||

| Clamping Force(KN) | 5500 | 6500 | 8000 | 12000 | ||||

| Mold Open Stroke(mm) | 600 | 700 | 700 | 800 | ||||

| Platen Size(mm) | 850×1000 | 950×1000 | 950×1000 | 1200×1300 | ||||

| Injection Volume(c.c) | 5000 | 8000 | 5000 | 8000 | 8000 | 12000 | 12000 | 15000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

Packing & Shipping

|

Container |

GW-S120L |

GW-S160L |

GW-S250L |

GW-S300L |

GW-S400L |

|

20GP |

1 unit |

1 unit |

1 unit |

– |

- |

|

40HQ |

3 units |

3 units |

2 units |

2 units |

2 units |

|

Packing |

Package 1: Rubber Injection Moulding Machine Main Body; |

||||

|

Package 2: Rubber Injection Moulding Machine Injection Unit |

|||||

|

Container |

GW-S550L |

GW-S650L |

GW-S800L |

GW-S1200L |

|

20GP |

– |

– |

– |

1 unit (one 40HQ + one 20GP) |

|

40HQ |

1 unit |

1 unit |

1 unit |

|

|

Packing |

Package 1: Injection Moulding Machine Main Body; |

|||

|

Package 2: Injection Moulding Machine Injection Unit |

||||

Main Features

● Vertical Clamping Unit & Angle-type Injection Unit

● High-pressure & High-precision Injection

● Modular-design & Multiple-combinations Solution

● Low Overall Height

● Humanized Operating System

● High-efficiency & High-stability Hydraulic System

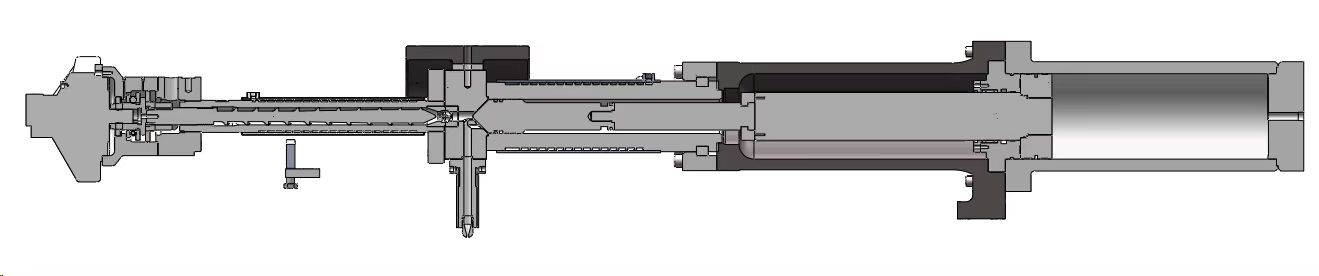

Injection System

● 1. F.I.L.O. Injection System, low rubber feeding height.

● 2. Single-Fixed-Cylinder Injection Unit, Horizontally Mounting On The Top Platen.

● 3. Steady Injection and High Injection accuracy & stability

● 4. Excellent Oil Cooling System for SCREW & BARREL ensuring good performance of rubber compound.

It adheres on the tenet “Honest, industrious, enterprising, innovative” to acquire new solutions regularly. It regards shoppers, success as its very own success. Let us establish prosperous future hand in hand for OEM Customized Wholesale Industrial Rotary Vane Vacuum Pump for Vacuum Metallurgy, We welcome new and aged prospects from all walks of existence to speak to us for potential company associations and mutual success!

OEM Customized China Rotary Vane Vacuum Pump and Vacuum Pump, As operation principle is “be market-oriented , good faith as principle, win-win as objective”, holding on “customer first, quality assurance, service first” as our purpose, dedicated to provide the original quality, create excellence service , we won the praise and trust in the industry of auto parts. In the future, We will provide quality product and excellent service in return to our customers , welcome any suggestions and feedback from all over the world.

-

China New Product Prototype Mold Silicone Rubbe...

-

Short Lead Time for Semi Automatic Compression ...

-

ODM Polyurethane High Pressure PU Foam Machiner...

-

10 Years Plastic Injection Mould Manufacturer F...

-

Massive Selection for Plastic Disposable Medica...

-

Customized High Performance Silicone Rubber Mol...