With advanced technologies and facilities, strict quality control, reasonable price, superior service and close co-operation with customers, we are devoted to providing the best value for our customers for OEM Customized Multi-Cavity LSR Liquid Silicone Rubber Auto Parts Mold Injection Mould, Being a young growing company, we might not the best, but we are trying our best to be your good partner.

With advanced technologies and facilities, strict quality control, reasonable price, superior service and close co-operation with customers, we are devoted to providing the best value for our customers for China Injection Mold and Silicone Mold, Our company, is always regarding quality as company’ s foundation, seeking for development via high degree of credibility , abiding by iso9000 quality management standard strictly , creating top-ranking company by spirit of progress-marking honesty and optimism.

Description

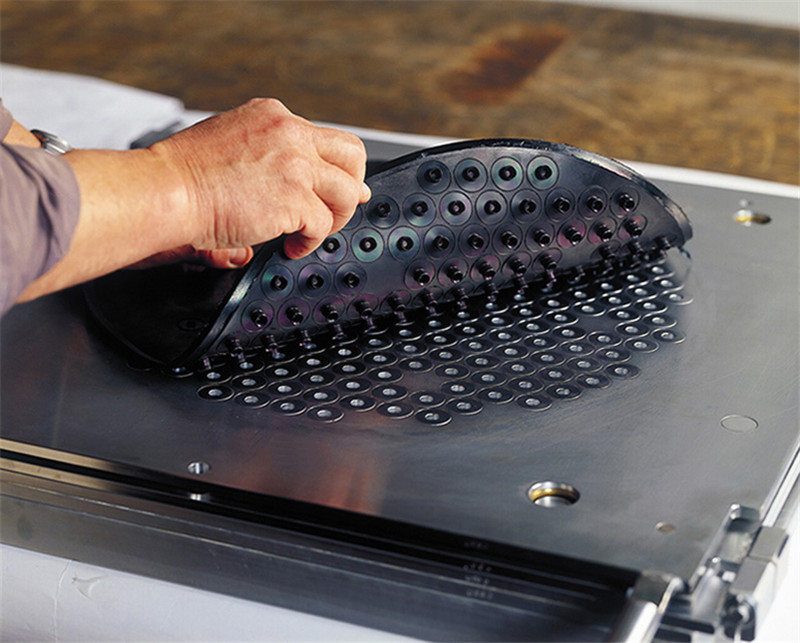

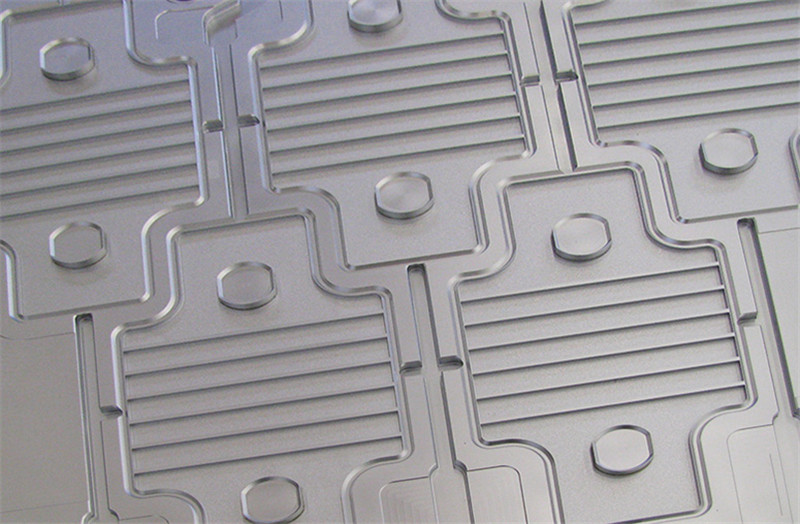

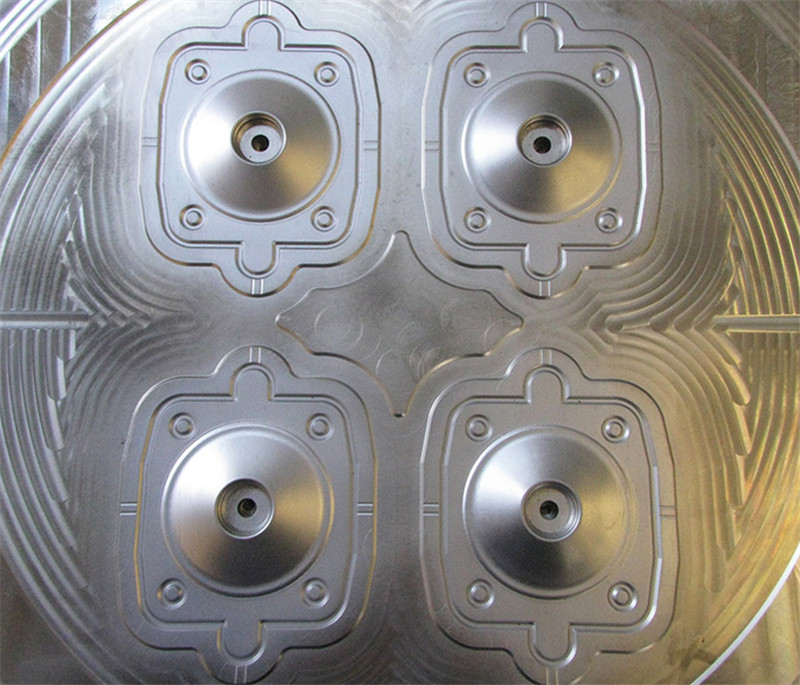

GOWIN Vacuum Compression Moulding Machine is a widely application model in the market making various rubber moulded parts; Compared with injection moulding process, compression molding rubber machine more suitable for small rubber parts with large quantity moulding cavity. With a Vacuum Chamber System, the moulding process will be more stable to avoid air bubble in rubber moulded components and also greatly improving production efficiency and reducing heating consumption compared with traditional rubber vulcanizing machine without vacuum system.

It is also a good choice for customers who having small demand of some rubber moulded products or starting new project business of rubber molding due to lower investment of the vacuum compression machine & simple rubber moulding process rather than injection molding process. Beside, the rubber press is available for transfer moulding also which could have better quality control for some critical rubber molded products need similar process of injection moulding machine.

GOWIN are providing high-end vulcanizing machine which apply same high performance component as rubber injection molding machine to ensure same user experience from GOWIN.

Vacuum Compression Machine

|

Model |

GW-VP200D |

GW-VP250D |

GW-VP300D |

|

Clamping Force(KN) |

2000 |

2500 |

3000 |

|

Mold Open Stroke(mm) |

250 |

250 |

300 |

|

Platen Size(mm) |

510×510 |

600×600 |

600×600 |

Packing & Shipping

| Container |

GW-VP200D |

GW-VP250D |

GW-VP300D |

| 20GP |

- |

- |

Open Top Container |

| 40HQ |

2 units |

2 units |

|

| Packing | Package 1: Rubber Molding Press Main Body | ||

| Package 2: Rubber Moulding Press Guarding & Auxiliary | |||

Main Features

● Double Independent Hydraulic System, Double Stations Working Independently.

● Large Vacuum Tank Machine Base, Fast Vacuum Speed.

● High Vacuum Degree, Ensure Rubber Products Stable Molding Quality.

● Strong Enough Machine Design.

● Humanized Design, Easy Operation & Convenient Maintenance.

● Multiple-combinations Optional Device.

With advanced technologies and facilities, strict quality control, reasonable price, superior service and close co-operation with customers, we are devoted to providing the best value for our customers for OEM Customized Multi-Cavity LSR Liquid Silicone Rubber Auto Parts Mold Injection Mould, Being a young growing company, we might not the best, but we are trying our best to be your good partner.

OEM Customized China Injection Mold and Silicone Mold, Our company, is always regarding quality as company’ s foundation, seeking for development via high degree of credibility , abiding by iso9000 quality management standard strictly , creating top-ranking company by spirit of progress-marking honesty and optimism.