We will constantly satisfy our respected customers with our good excellent, superior value and superior assistance due to we’re additional experienced and far more hard-working and do it in cost-effective way for OEM Customized Momu LSR Rbber Injection Molding Vacuum Molding Machine Rubber Press Baby Bottle Making Machine, We invitations you and your company to prosper along with us and share a vibrant long term in worldwide current market.

We will constantly satisfy our respected customers with our good excellent, superior value and superior assistance due to we’re additional experienced and far more hard-working and do it in cost-effective way for China Rubber Injection Molding Machine and Silicone Injection Moulding Machine, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

Description

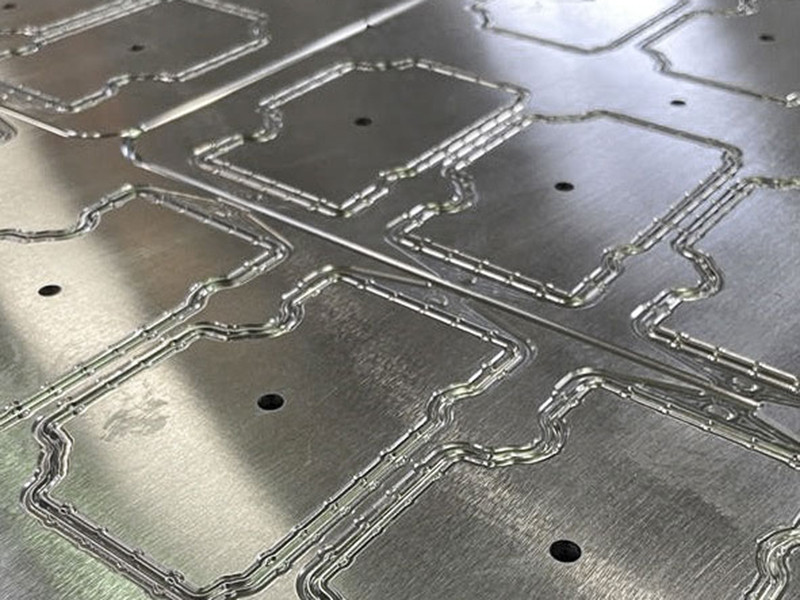

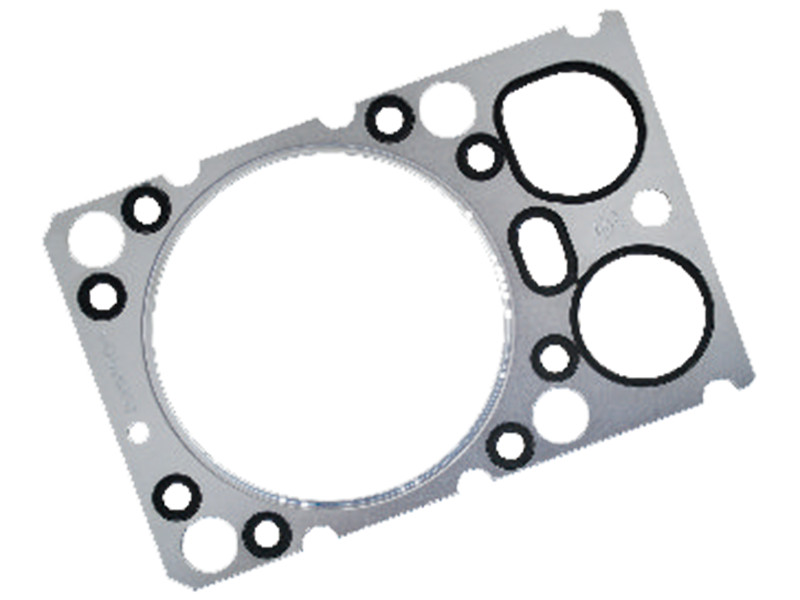

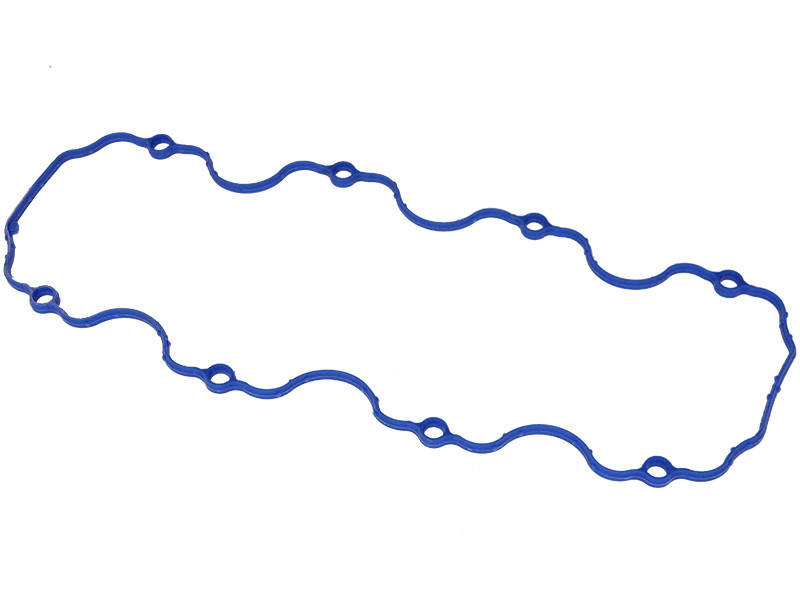

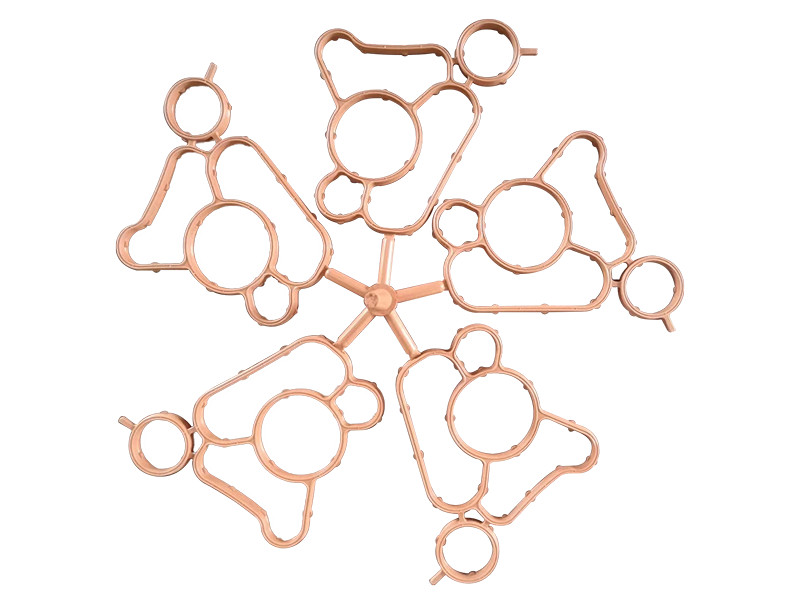

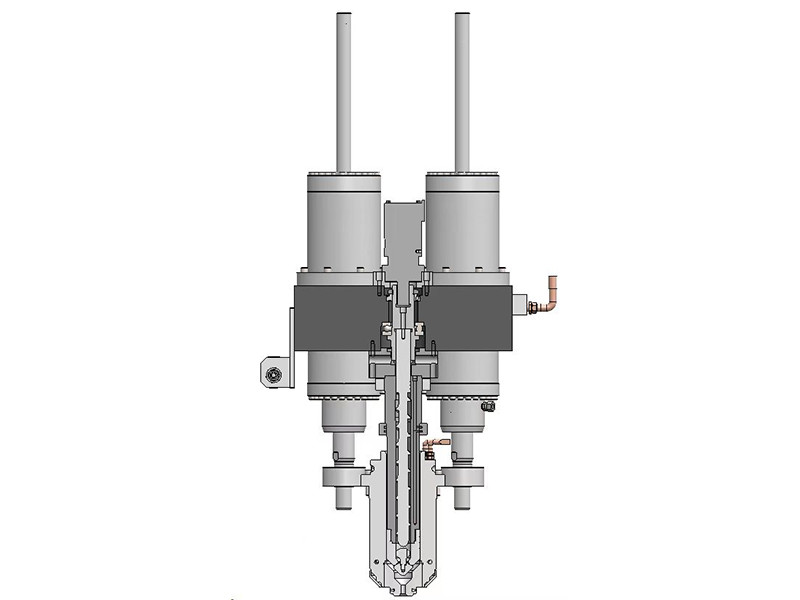

The GW-RF Series F.I.F.O Vertical Rubber Injection Moulding Machine are GOWIN High-End Rubber Moulding Machine Models. The machines are equipped with a VERTICAL CLAMPING SYSTEM & F.I.F.O. VERTICAL INJECTION SYSTEM, suitable for various rubber molded parts, especially precision rubber sealing products in the field of automobile, energy, railway transportation, industry, medical care and household appliances, etc.

With the High performance of the F.I.F.O. Injection System, the Rubber Moulding Machine is available to match all kinds of rubber moulding such as NR, NBR, EPDM, SBR, HNBR, FKM, SILICONE, ACM, AEM, etc.

With High-end SERVO SYSTEM, the Rubber Molding Machine is greatly improving production efficiency and reducing labor costs. It is an idea of Rubber Molding Machine Models involving automation rubber molding. Also, the Rubber Machine is available for HOT RUNNER MOLD & COLD RUNNER BLOCK SYSTEM MOLD (optional solutions for CRB mold).

GW-RF Main Specification

| Model | GW-R120F | GW-R160F | GW-R250F | GW-R300F | ||||

| Clamping Force(KN) | 1200 | 1600 | 2500 | 3000 | ||||

| Mold Open Stroke(mm) | 450 | 500 | 500 | 500 | ||||

| Platen Size(mm) | 430×500 | 500×500 | 560×630 | 600×700/600×800 | ||||

| Injection Volume(c.c) | 1000 | 1000 | 500 | 1000 | 2000 | 500 | 1000 | 2000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

| Model | GW-R400F | GW-R550F | GW-R650F | ||||||

| Clamping Force(KN) | 4000 | 5500 | 6500 | ||||||

| Mold Open Stroke(mm) | 600 | 600 | 700 | ||||||

| Platen Size(mm) | 700×800 | 850×1000 | 950×1000 | ||||||

| Injection Volume(c.c) | 1000 | 2000 | 3000 | 1000 | 2000 | 3000 | 1000 | 2000 | 3000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

Packing & Shipping

|

Container |

GW-R120F |

GW-R160F |

GW-R250F |

|

20GP |

1 unit |

1 unit |

1 unit |

|

40HQ |

3 units |

3 units |

2 units |

|

Packing |

Package 1: Rubber Machine Main Body; |

||

|

Package 2: Rubber Machine Injection Unit |

|||

|

Container |

GW-R550F |

GW-R650F |

|

20GP |

– |

– |

|

40HQ |

1 unit |

1 unit |

|

Packing |

Package 1: Molding Machine Main Body; |

|

|

Package 2: Molding Machine Injection Unit |

||

Main Features

● Precise Injection

● Modular-design & Multiple-combinations Solutions

● Low-bed & Optimized Structure

● Humanized Operating System

● High-efficiency &High-stability& High-Energy-Saving Servo Hydraulic System

Injection System

● F.I.F.O. Injection System, Moving-Cylinder Vertical Injection

● High-speed & High-pressure & High-precision Injection

● Short Injection Nozzle Design, Less injection pressure loss

● Available for Various Special Rubber Compound Such as VITON

We will constantly satisfy our respected customers with our good excellent, superior value and superior assistance due to we’re additional experienced and far more hard-working and do it in cost-effective way for OEM Customized Momu LSR Rbber Injection Molding Vacuum Molding Machine Rubber Press Baby Bottle Making Machine, We invitations you and your company to prosper along with us and share a vibrant long term in worldwide current market.

OEM Customized China Rubber Injection Molding Machine and Silicone Injection Moulding Machine, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

-

High Performance High-Quality Plastic Mould Man...

-

Excellent quality Professional Custom Molded Fl...

-

Massive Selection for China Manufacturer Soft a...

-

Liquid Silicone Rubber Baby Soother 85ton Injec...

-

China Supplier Customized Transparent Clear Liq...

-

Customized High Performance Silicone Rubber Mol...