I. Current Market Situation of Solid Silicone Injection Machines

The demand for solid silicone injection machines in the power industry has shown a significant growth trend in recent years. In the production process of power cable accessories, solid silicone injection machines play a vital role. Its ability to efficiently and accurately inject solid silicone into molds produces high-quality power cable accessories that meet the stringent requirements of the power industry for insulation, tightness and durability.

At present, there are many solid silicone injection machine brands on the market. For example, Gowin Precision Machinery Co., Ltd. cable accessories design, with its professional performance and reliable quality has occupied a certain share in the market. In addition, there are many other brands are constantly working to meet the needs of the power industry.

With the continuous development of the power industry and the increasing demand for high-quality cable accessories, the market prospects for solid silicone injection machines are broad. In the future, it is expected that more enterprises will invest in the research and development and production of solid silicone injection machines, and promote the continuous upgrading and innovation of products to better meet the needs of the power industry.

II.Features of Solid Silicone Injection Machines

Our equipment has the best rubber material self-cleaning function, injection cylinder fixed, natural back pressure, effectively reduce energy consumption. The large lift of the platform provides more space for production operations. The injection closed-loop control and proportional digital back pressure design ensure the accuracy and stability of the injection process. The remote control function makes the operation more convenient and efficient, the high efficiency and low energy consumption variable piston pump implements the European CE safety standard, and the real-time printing production data function provides strong support for production management.

Here are the best feature of our Solid Silicone Injection Machine for Energy Industry:

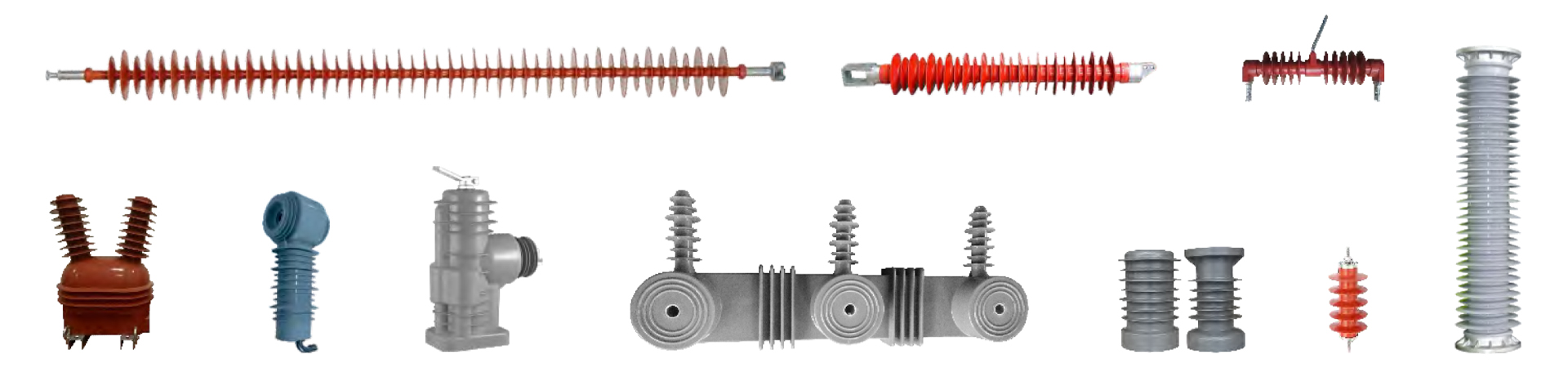

(1)Specialized Design for Solid Silicone Product Molding inEnergy Industry,such as for Polymer Insulator, PolymerFuse Cut-out, Polymer Transformer etc.

(2)Specialized Designed Angle-type Injection System forSolid Silicone.

(3)Reasonable Machine Layout, Convenient for Operationin All Access.

(4)Strong Enough Mechanical Structure to Ensure StableMolding Quality.

(5)Large Enough Silicone Stuffer On Floor.

III.Applications in the Power Industry

Solid silicone injection machine has an important application in the power communication industry. In the power industry, silicone products are widely used for their good electrical breakdown resistance and insulation characteristics. Solid silicone injection machine mainly produces products with no rules and no fixed shape, such as solid silicone insulators for power terminals. These products can withstand ultra-high voltages and are widely used in transmission lines and terminals. In contrast, the products of the silicone tube extrusion process in the field of power are based on regular round tubes, such as power cold shrink silicone tubes. Although the two are different in shape, they can meet the requirements of the power industry for insulation and high voltage resistance.

IV. Future Prospects

With the continuous development of the power industry and the continuous progress of technology, the application prospect of solid silicone injection machine in the power industry is very broad. On the one hand, with the acceleration of smart grid construction, the demand for high-performance and high-reliability power cable accessories will continue to grow. Solid silicone injection machines produce cable accessories with excellent insulation, sealing and durability to meet the stringent requirements of smart grid equipment. On the other hand, the rapid development of new energy fields, such as wind power, photovoltaic, etc., has also brought new market opportunities for solid silicone injection machines. The demand for cable accessories in these new energy fields is equally huge, and the characteristics of solid silicone injection machines give them a unique advantage in the manufacture of new energy power equipment.

Post time: Nov-11-2024