Silicone Rubber Injection Molding Machine Market report provides a comprehensive analysis of the current trends, growth drivers, challenges, and opportunities within the Silicone Injection Molding Machine industry. The report delves into the market’s key segments, including product types, applications, and regional markets, offering valuable insights for investors, stakeholders, and industry player. Moreover, the report evaluates the demand-supply dynamics and examines the market’s growth potential during the forecast period. It highlights the emerging market trends and investment opportunities that can help stakeholders make informed decisions. Additionally, the challenges faced by market participants are analyzed, along with the possible mitigation strategies.

What Are the Different Types of Silicone Injection Molding Machine on the Market?

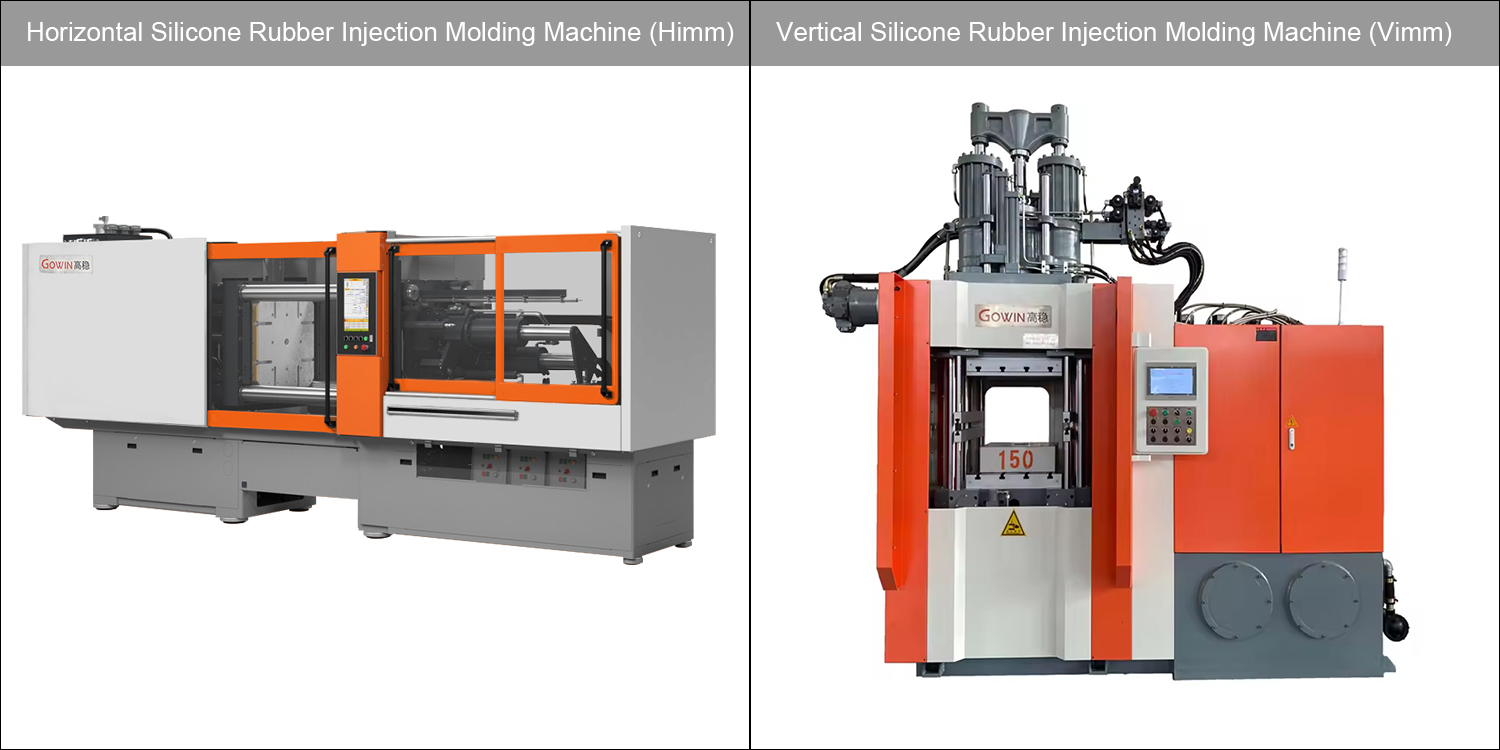

- Horizontal Silicone Rubber Injection Molding Machine (Himm)

- Vertical Silicone Rubber Injection Molding Machine (Vimm)

Types help provide a comprehensive understanding of the diverse landscape within the Silicone Injection Molding Machine market. Keep in mind that the categorizations can evolve as technology advances and market trends change.

What Factors are the power source for the Silicone Injection Molding Machine Market’s Growth?

- Medical Decice

- Aerospace

- Automotive Component

These applications highlight the versatility of Silicone Injection Molding Machine and their potential to enhance visual experiences across a wide range of settings and industries.

According to latest study, the global Silicone Injection Molding Machine market size was valued at USD 360.1 million in 2023. With growing demand in downstream market, the Silicone Injection Molding Machine is forecast to a readjusted size of USD 415.8 million by 2030 with a CAGR of 2.1% during review period.

China is the largest Silicone Injection Molding Machine market with about 39% market share. Europe is follower, accounting for about 19% market share.

Gowin as a member of Chinese manufacturers, we accurately grasp the rubber products molding process and customer needs, to provide customers with the best molding solutions! To provide customers with “efficient, stable, energy-saving” rubber molding equipment!

Post time: Mar-28-2024