The rubber products industry plays a pivotal role in the global manufacturing sector, touching almost every aspect of modern life. From automotive parts to medical devices, and from construction materials to consumer goods, rubber products are integral to countless industries. However, as the world evolves, so too does the rubber industry—shaped by technological advancements, shifting consumer demands, and new environmental regulations.

In this article, we’ll explore key trends in the rubber products industry, the latest innovations in rubber processing machinery, and the market prospects for the years ahead.

Key Trends in the Rubber Products Industry

1.Sustainability and Green Innovation

Sustainability is a growing focus across all industries, and rubber is no exception. Traditional rubber manufacturing processes often rely on petroleum-based products, but there is a significant push towards more eco-friendly alternatives. The rise of bio-based rubbers and recycled rubber is transforming production methods. With environmental concerns at the forefront, consumers and manufacturers are increasingly looking for products made from renewable resources or recycled materials. This trend not only helps reduce carbon footprints but also opens new market opportunities for companies that invest in green innovation.

2.Customization and High-Performance Products

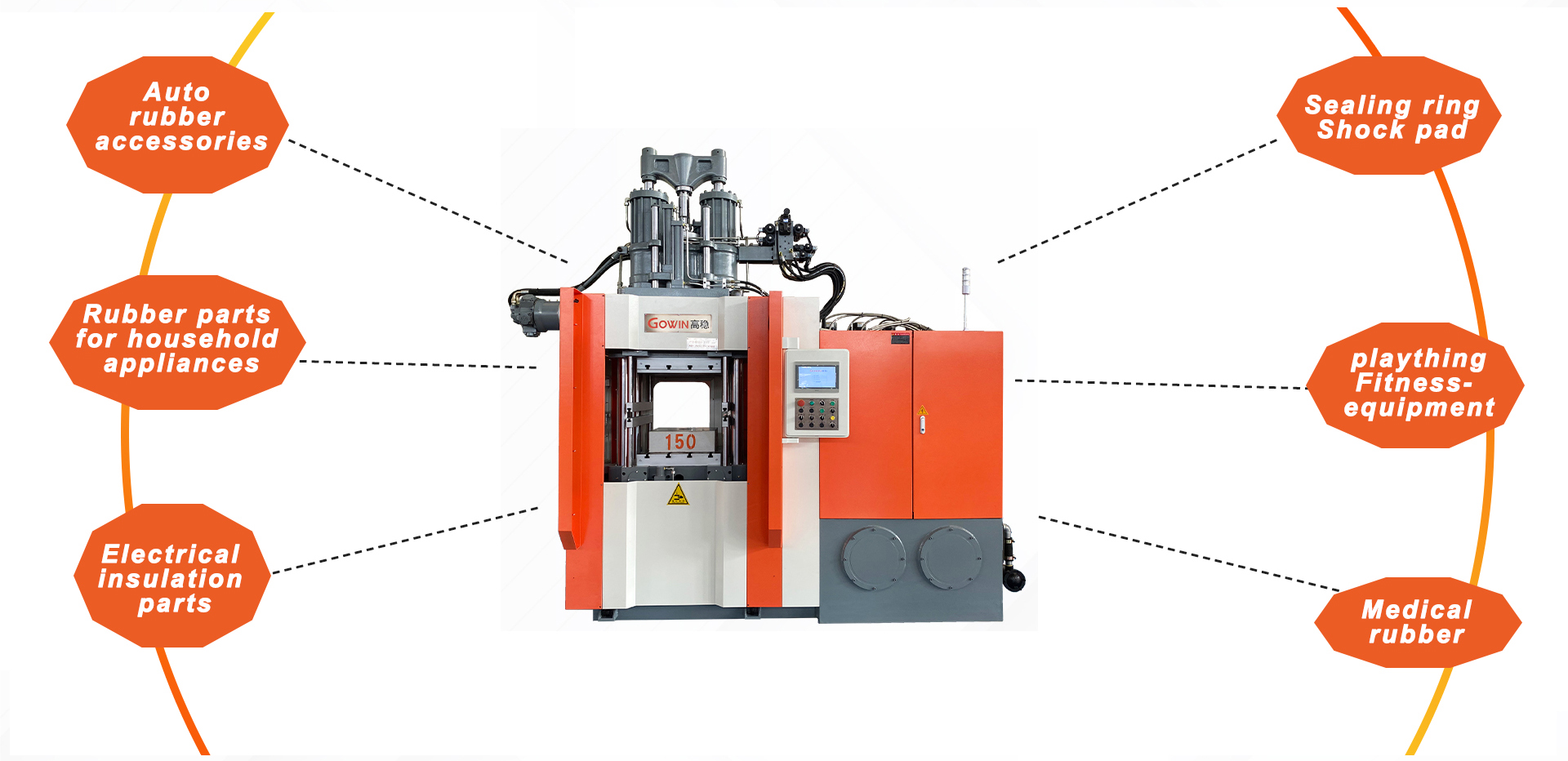

As industries become more specialized, there is an increasing demand for customized rubber products that meet specific performance requirements. Whether it’s for high-tolerance seals in aerospace applications or advanced elastomers used in medical devices, the demand for precision-engineered, high-performance rubber products is on the rise. This trend pushes manufacturers to invest in advanced materials science and cutting-edge technology to meet increasingly complex customer needs.

3.Automation and Digitalization

Like many other manufacturing sectors, the rubber industry is embracing automation and digital technologies to enhance production efficiency and reduce costs. The use of Industry 4.0 technologies, such as smart factories, real-time data analytics, and AI-driven production lines, is helping companies to optimize their operations and achieve higher levels of precision. This has the potential to transform the rubber products sector, making it more agile and responsive to market demands.

4.Globalization and Supply Chain Optimization

The global demand for rubber products continues to expand, especially in developing economies. This has led to more complex supply chains and a growing emphasis on global sourcing strategies. However, the COVID-19 pandemic highlighted vulnerabilities in supply chains, leading many companies to rethink their sourcing and inventory management strategies. This trend points to a future where companies will increasingly rely on more flexible, resilient, and diversified supply chains to meet global demand.

Advances in Rubber Processing Machinery

The evolution of rubber processing machinery is closely tied to the demands of modern industries. The rise of smart manufacturing and advanced materials has spurred innovation in machinery, making the production process more efficient and precise. Here are some of the latest trends in rubber processing technology:

1.High-Throughput Extrusion and Injection Molding Machines

As the demand for rubber products grows, manufacturers need machines that can handle high-volume production while maintaining quality. Extrusion and injection molding technologies have advanced significantly, offering higher throughput rates and more precise control over the molding process. Newer machines are equipped with automated systems for precise material mixing, temperature control, and molding parameters, all of which contribute to better consistency and reduced waste.

2.Smart and Connected Machinery

With the rise of the Internet of Things (IoT), rubber processing machinery is becoming more connected and intelligent. Machines equipped with sensors and cloud-based monitoring systems can provide real-time insights into machine performance, allowing for predictive maintenance, optimization of process parameters, and overall efficiency improvements. Smart machines can also be programmed to automatically adjust settings based on real-time data, reducing human intervention and minimizing errors.

3.Energy Efficiency and Waste Reduction

In today’s environmentally-conscious world, reducing energy consumption and waste has become a priority for many rubber manufacturers. New rubber processing machinery is being designed with energy-efficient motors, recyclable components, and closed-loop systems to minimize energy use and material waste. These innovations not only reduce operating costs but also contribute to the industry's broader sustainability goals.

4.Advanced Curing and Vulcanization Technology

Curing (vulcanization) is a crucial step in rubber processing that determines the material’s strength and durability. Recent advancements in vulcanization technology focus on improving curing time, reducing energy consumption, and enhancing the performance of finished products. For example, microwave curing and infrared heating technologies are being explored as alternatives to traditional methods, offering faster curing times and improved energy efficiency.

Market Prospects: A Bright Future Ahead

The global rubber products market is expected to continue expanding, driven by the growing demand for rubber in industries such as automotive, healthcare, construction, and consumer goods. According to a report by Grand View Research, the global rubber products market is estimated to reach $480 billion in 2023 and is expected to grow to $590 billion by 2028, with an average annual growth rate of 4%. According to research by MarketsandMarkets, the rubber processing equipment market will grow at an annual rate of about 5-6% until 2026 and is expected to reach a total value of $13 billion.

Conclusion

The rubber products industry is undergoing a transformation driven by sustainability, technological innovation, and evolving market demands. From advanced processing machinery to new material innovations, the sector is embracing change to meet the challenges and opportunities of the future. Companies that invest in automation, digitalization, and green technologies will be well-positioned to capitalize on the growth prospects in this dynamic industry.

As we look ahead, the global rubber products market presents significant opportunities, with evolving consumer preferences, advancements in manufacturing technology, and growing demand across a wide range of industries. For businesses in the rubber industry, the key to success will be staying ahead of these trends and continuously innovating to meet the needs of an increasingly complex and competitive market.

Post time: Nov-26-2024