The automotive industry is continuously evolving, with a growing emphasis on advanced materials and manufacturing processes. One of the significant trends in recent years is the increasing application of rubber injection molding in the production of automotive components. This technique offers numerous benefits, including precision, efficiency, and the ability to handle complex designs.

Advances in Rubber Injection Molding

Rubber injection molding, a process that molds uncured rubber by injecting it into a metal mold, has become a preferred method for manufacturing various automotive parts due to its precision and efficiency. Unlike traditional molding methods, injection molding can produce parts with faster cycle times and higher consistency, making it ideal for high-volume production.

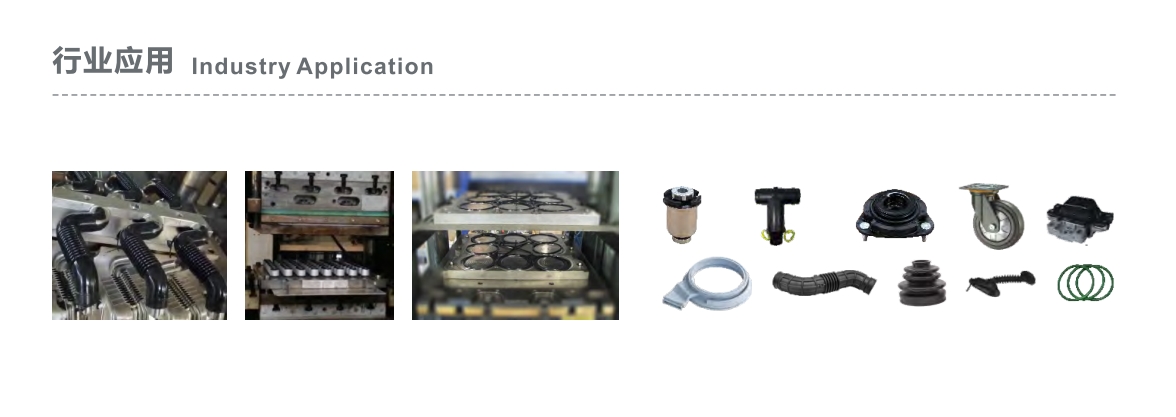

Key Applications in the Automotive Sector

1. Seals and Gaskets: Rubber injection molding is extensively used to produce seals and gaskets, which are critical for preventing leaks and ensuring the integrity of various systems within a vehicle. These components must withstand high pressures and temperatures, making the durability and precision offered by injection molding highly valuable.

2. Adaptive Drive Beam (ADB) Lens Optics: At the NPE 2024, Krauss-Maffei showcased the use of Dow’s SILASTIC™ MS-5002 Moldable Silicone in producing ADB lens optics for vehicles. This innovation highlights the capability of rubber injection molding to handle intricate designs and materials with specific performance requirements.

3. Connector Seal: Another notable application is the production of connector seals using Dow XIAMETER™ RBL-2004-50 LSR. These seals are essential for ensuring reliable electrical connections in vehicles, demonstrating the versatility of rubber injection molding in producing parts with high tear strength and low compression set.

4. Battery Dividers for Electric Vehicles (EVs): As the automotive industry shifts towards electric vehicles, there is a growing need for specialized rubber components such as battery dividers. These parts require materials that offer high transparency and quick curing times, characteristics well-suited to rubber injection molding processes.

Benefits and Future Outlook

The use of rubber injection molding in automotive manufacturing offers several advantages:

- Precision and Consistency: The process ensures that each part meets stringent quality standards, reducing the likelihood of defects.

- Efficiency: Faster cycle times translate to higher production rates, essential for meeting the demands of the automotive industry.

- Versatility: The ability to mold various types of rubber, including high-performance elastomers, allows for the production of a wide range of components.

As the automotive industry continues to innovate, the role of rubber injection molding is expected to grow. The development of new materials and technologies will likely further enhance the capabilities of this manufacturing process, supporting the production of increasingly sophisticated automotive components.

Post time: May-27-2024