Ⅰ. Introduction to LSR Molding Machine for Cable Accessories

An LSR molding machine for cable accessories is a key equipment in the cable industry. It molds liquid silicone rubber into cable accessories vital for cable function and durability.The importance of these machines is huge. Cable accessories made by them have great electrical insulation due to liquid silicone rubber's high dielectric strength, safeguarding cables from faults and ensuring power and signal transmission.They're highly resistant to heat, cold, moisture, and chemicals, suitable for various applications, indoor or outdoor.Besides functionality, they look good. LSR machines' precision molding creates sleek, uniform designs, improving cable installation's appearance.Industry reports show rising demand for LSR-molded cable accessories. As the cable industry grows, the need for quality accessories grows too. LSR molding machines lead in fulfilling this need, offering manufacturers an efficient, cost-effective way to make accessories meeting modern application demands.

Ⅱ. Features and Advantages

(1)Precision and Quality

The LSR molding machine for cable accessories is famed for its outstanding precision. Leveraging advanced technology and precise engineering, it molds cable accessories with high accuracy. Injection molding, a key polymer processing method, is utilized. The precisely designed mold cavity enables the creation of perfectly fitting and optimally performing accessories. Industry data shows that the machine can achieve a tolerance as low as a few micrometers. This precision not only secures electrical insulation but also boosts the durability and reliability of the accessories. The high dielectric strength of liquid silicone rubber is further amplified by the accurate molding process, leading to top-notch products that fulfill the cable industry's strict demands.

(2)Efficiency and Productivity

The LSR molding machine is engineered to boost production efficiency and output. Its automated procedures and short cycle times allow for a large volume of cable accessories to be produced rapidly. Some models can complete a molding cycle within minutes, slashing production time. The machine can operate continuously with minimal downtime, vital for manufacturers facing rising demand. High-quality materials and components ensure smooth and reliable operation, cutting maintenance and repair costs. Enhanced production efficiency empowers manufacturers to enhance productivity and gain a competitive edge.

(3)Versatility and Customization

The LSR molding machine is highly adaptable, capable of handling diverse cable accessories like connectors and grommets, molding liquid silicone rubber into various shapes and sizes. This versatility suits a broad spectrum of cable industry applications. Additionally, it offers customization. Manufacturers can tailor the design and specs of cable accessories to specific needs, enabling the production of unique and specialized products. With such versatility and customization, the machine offers manufacturers the flexibility to address the varying demands of different customers and applications.

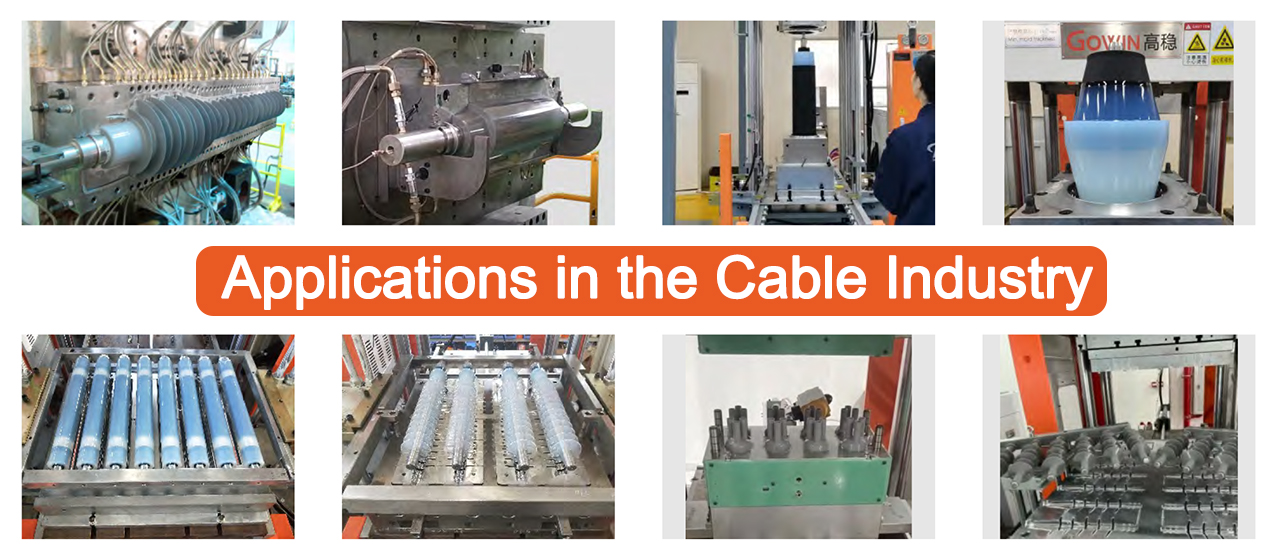

Ⅲ.Applications in the Cable Industry

(1)Wide Range of Cable Accessories The LSR molding machine for cable accessories can fabricate a wide variety of products. Connectors, vital for secure cable connections, are precisely molded. Grommets, which safeguard cables from abrasion during passage through openings, are also produced accurately. Cable bushings, offering insulation and mechanical protection, can be efficiently made. Industry data reveals that cable seals, preventing moisture and dust ingress, can also be manufactured.

(2)Enhancing Cable Performance LSR-molded cable accessories are crucial for cable performance and durability. The liquid silicone rubber's high dielectric strength ensures excellent electrical insulation, minimizing electrical faults and enabling safe power and signal transmission. These accessories resist heat, cold, moisture, and chemicals. In extreme temps, they maintain functionality, and in humid conditions, seals and grommets keep moisture out, reducing corrosion and short-circuit risks. Bushings and grommets' mechanical protection extends cable lifespan. The precision-molded sleek designs enhance aesthetics and cable management. Overall, these accessories are essential for cable optimization and longevity across applications.

Post time: Nov-15-2024