In recent years, the rubber injection machinery industry has witnessed a surge in innovation and technological advancements. Manufacturers are constantly striving to meet the evolving demands of the market while enhancing efficiency and product quality. Let’s explore some of the latest developments in this dynamic sector.

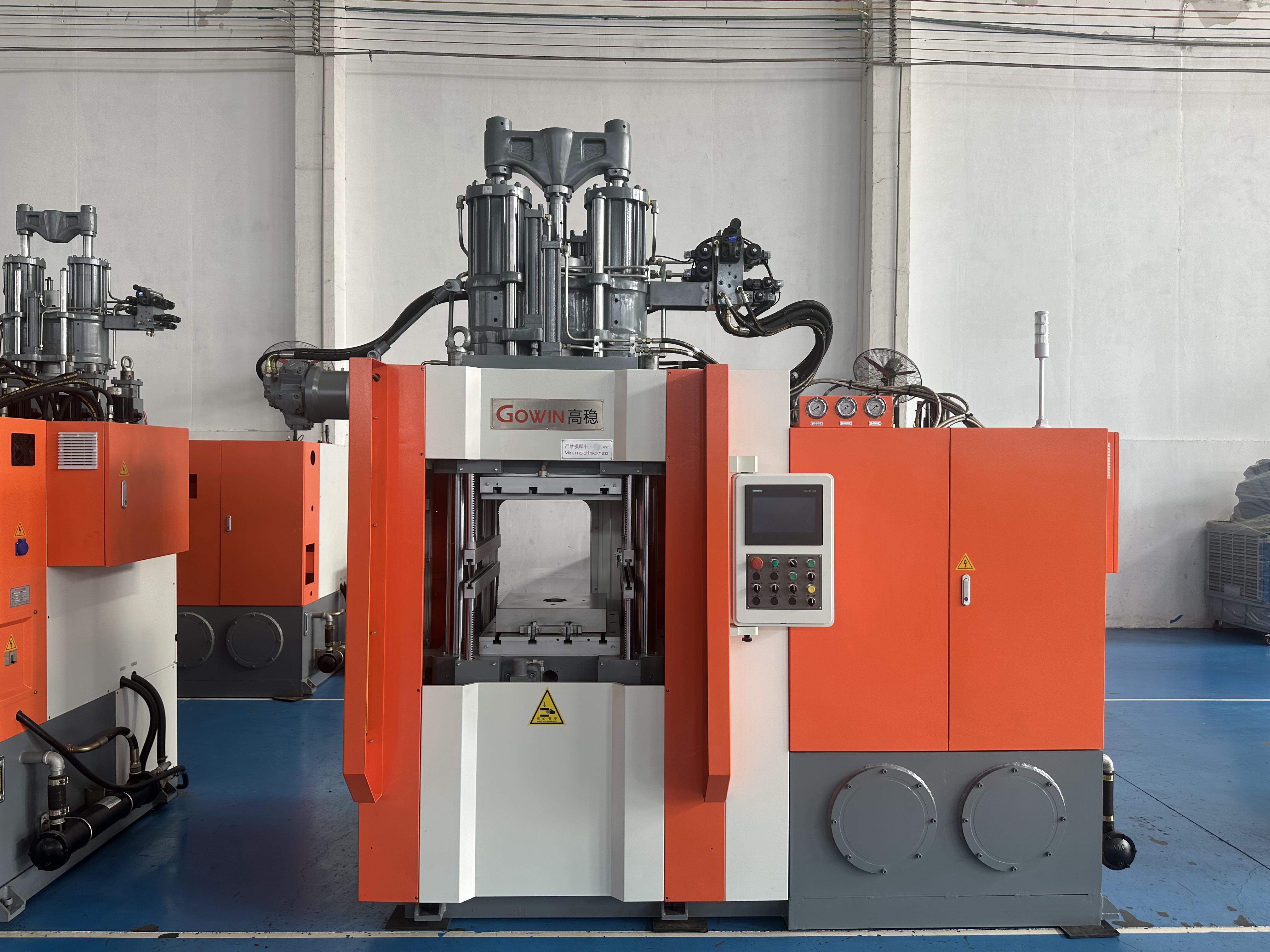

Leading companies in the rubber injection machinery sector have introduced cutting-edge technologies to improve production processes. Advanced control systems, precision molding techniques, and automation have revolutionized the way rubber components are manufactured. These innovations not only ensure higher productivity but also enable greater customization and quality control.

In response to growing environmental concerns, many manufacturers are incorporating sustainable practices into their operations. From energy-efficient machinery to the use of eco-friendly materials, the industry is committed to reducing its carbon footprint. By adopting sustainable practices, companies aim to minimize waste generation and promote environmental stewardship.

The rubber injection machinery market is experiencing significant growth driven by various factors such as the automotive industry’s demand for precision-engineered rubber components and the increasing use of rubber in medical devices. Additionally, emerging applications in sectors like electronics and consumer goods are further driving demand for advanced injection molding technologies.

The rubber injection machinery industry continues to evolve, driven by innovation, sustainability, and market demand. With ongoing technological advancements and a focus on environmental responsibility, manufacturers are well-positioned to address the challenges and opportunities of the future. As the industry embraces change, it remains at the forefront of shaping the way rubber products are manufactured and utilized across diverse sectors.

Post time: May-17-2024