DeepSeek views the development of the rubber injection machine industry in 2025 as a dynamic landscape shaped by technological innovation, sustainability imperatives, and evolving market demands. Here’s our perspective on key trends and opportunities:

1. Technology-Driven Advancements

- **Smart Manufacturing Integration**: Rubber injection machines will increasingly adopt IoT connectivity, AI-driven process optimization, and predictive maintenance to enhance efficiency and reduce downtime. Real-time data analytics will enable adaptive control for complex molding tasks.

- **Precision and Flexibility**: Demand for high-precision components (e.g., micro-seals, medical devices) will push advancements in multi-axis control, nano-level accuracy, and rapid mold-switching capabilities.

- **Material Compatibility**: Machines will evolve to handle advanced materials like silicone, liquid rubber, and bio-based compounds, requiring improved temperature/pressure controls and curing systems.

2. Market Expansion and Applications

- **Electric Vehicles (EVs)**: Growth in EV production will drive demand for rubber seals, gaskets, and vibration-damping components, boosting rubber injection machine sales in automotive supply chains.

- **Healthcare and Consumer Goods**: Sterile, medical-grade rubber products (e.g., syringe plungers, wearable device seals) and customized consumer items (e.g., ergonomic grips) will create niche opportunities.

- **Industrial Automation**: Rubber parts for robotics and machinery (e.g., grippers, shock absorbers) will see steady demand as automation expands globally.

3. Sustainability as a Core Focus

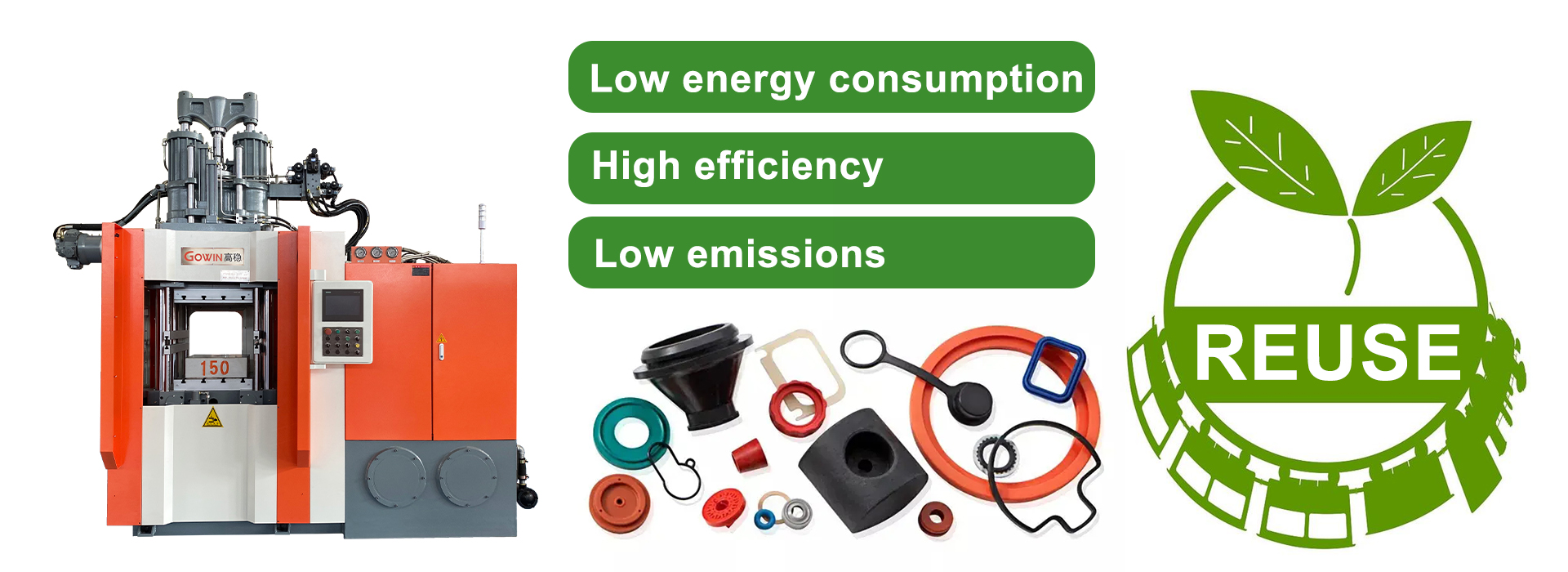

- **Energy Efficiency**: Machines with servo-electric systems will dominate, replacing hydraulic models to cut energy consumption by 30–50%, aligning with global carbon neutrality goals.

- **Circular Economy**: Adoption of recyclable/biodegradable rubber materials will require machines to adapt processing parameters (e.g., lower curing temperatures, faster cycles).

- **Emission Reduction**: Closed-loop systems and VOC-free processes will become critical to comply with stringent environmental regulations (e.g., EU REACH).

DeepSeek's Outlook

By 2025, the rubber injection machine industry will likely experience **moderate growth (4–6% CAGR)**, driven by EV expansion, smart manufacturing upgrades, and sustainability mandates. Success will depend on:

- **Agility in R&D**: Rapid adaptation to material and regulatory shifts.

- **Digital Transformation**: Leveraging AI/ML for predictive quality control and process optimization.

- **Strategic Partnerships**: Collaborating with material suppliers and end-users to co-develop tailored solutions.

Companies that balance technological leadership with sustainability and regional market insights will lead the next phase of industry evolution.

Post time: Feb-14-2025