Description

Why choose the Rubber&Silicone Moulding Turnkey Solution?

Moulding Turkey Solution Simplify the Rubber&Silicone Injection Moulding!

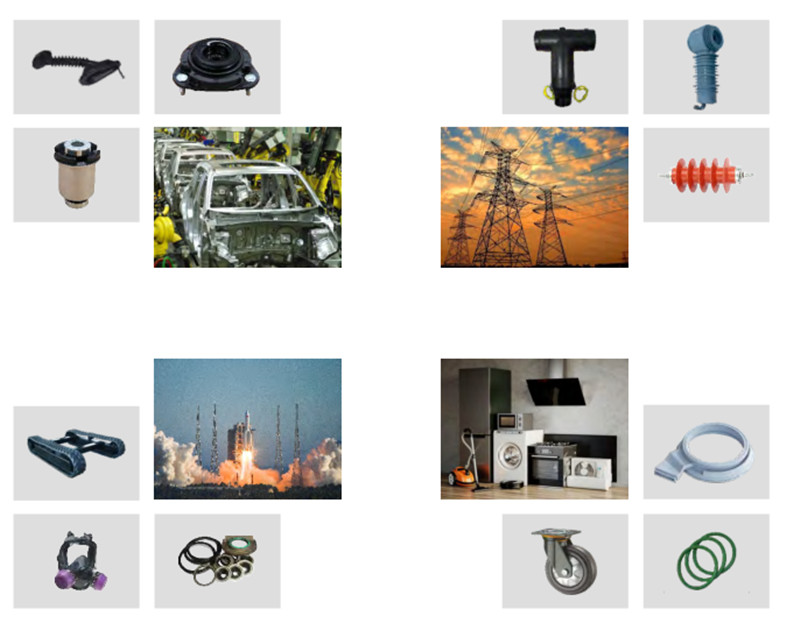

GOWIN Insisting on market-oriented, accurately mastering molding process of rubber molded parts and customer demand, combined with outstanding design ability & excellent assembling technology & consummate service system, GOWIN is dedicated to providing “High-efficiency, High-stability, Energy-saving” rubber molding machinery & molding solutions to enhance customer competitive strength and user experience.

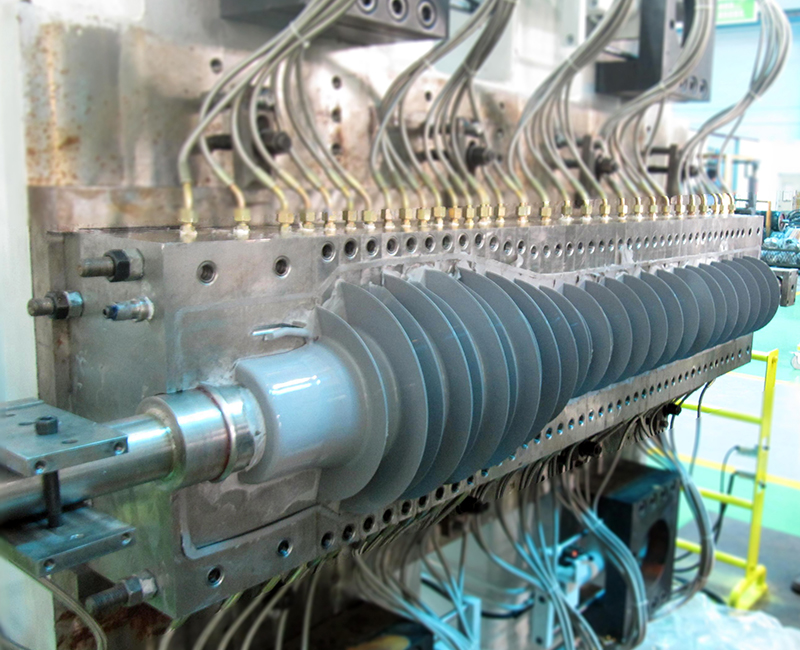

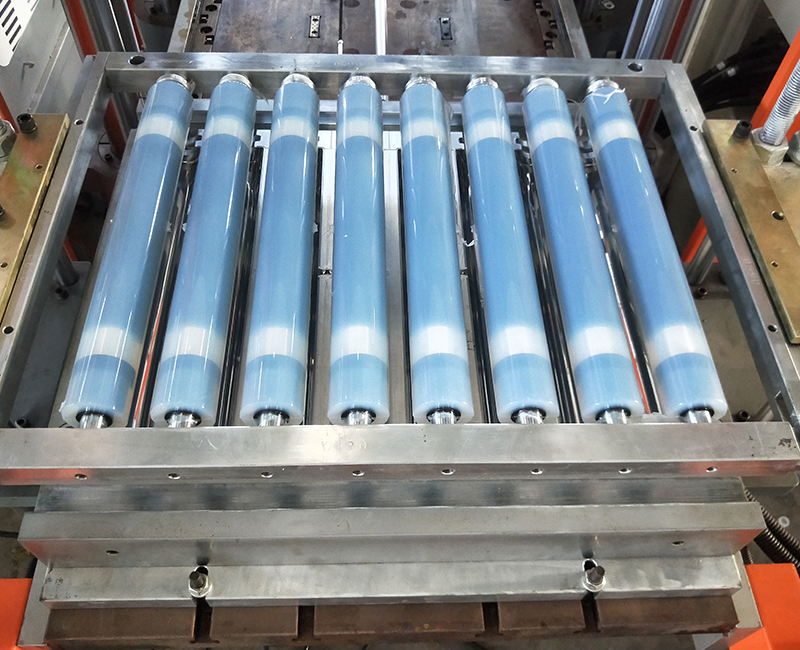

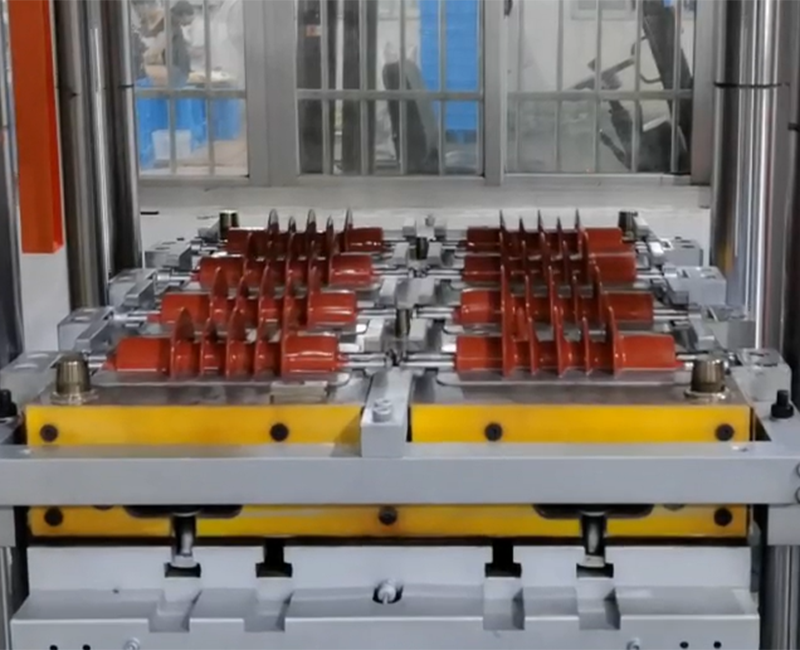

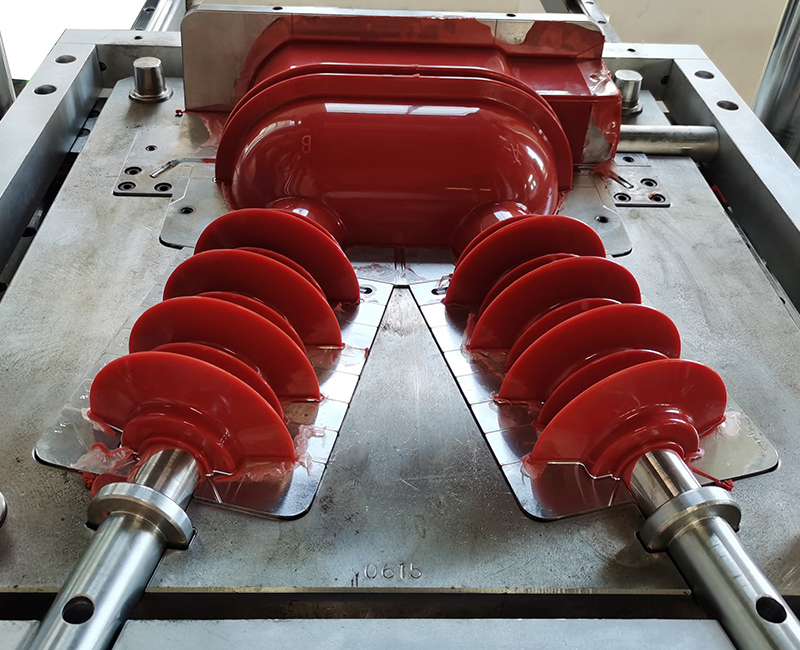

GOWIN provide various rubber moulding machine, including vertical rubber injection machine, C-frame rubber injection machine, horizontal rubber injection machine, solid silicone injection machine, LSR molding machine, vacuum compression molding machine, compression press and tailor-made high-end rubber molding machine etc.

In doing this the rubber machinery manufacturer can be setting themselves up for difficulties down the road. This is because mold builders or makers often lack the knowledge that have to acquired through many years of trial and error.

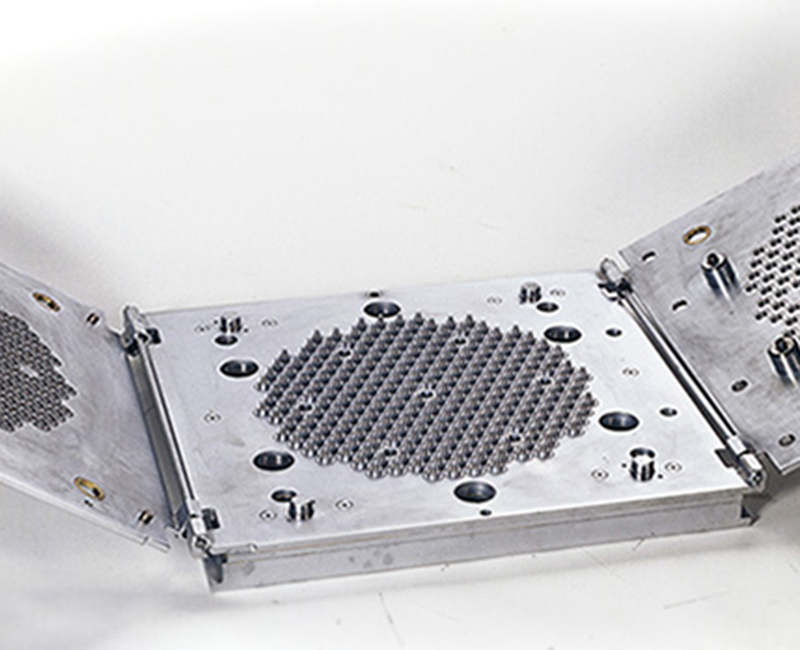

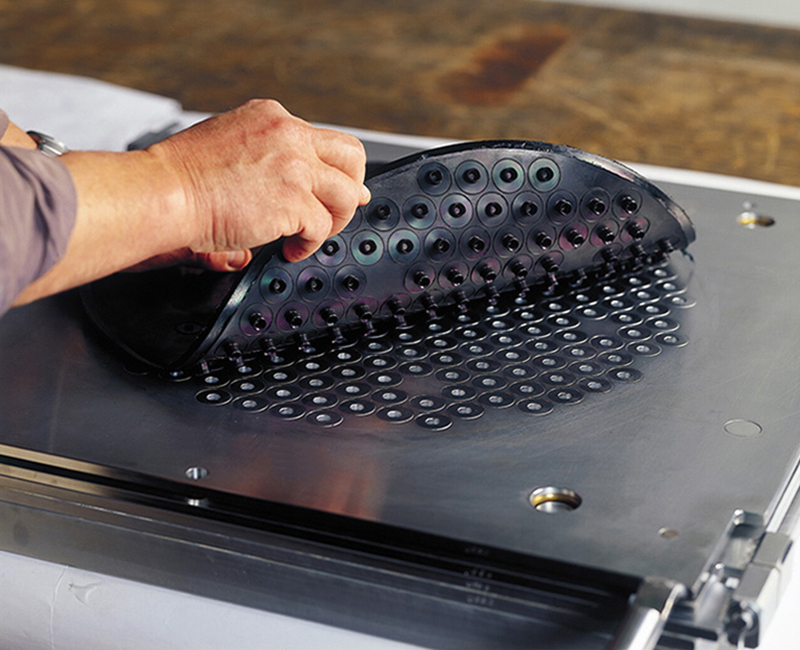

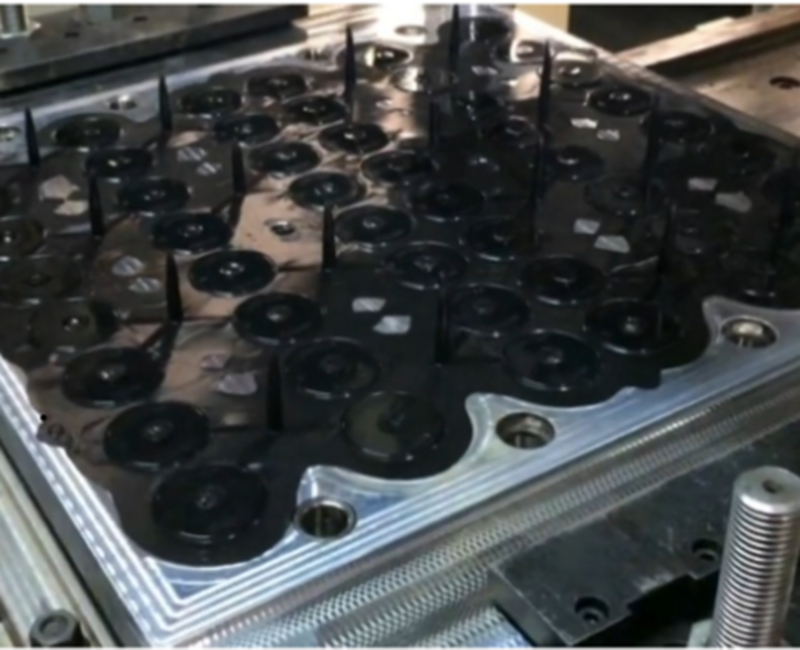

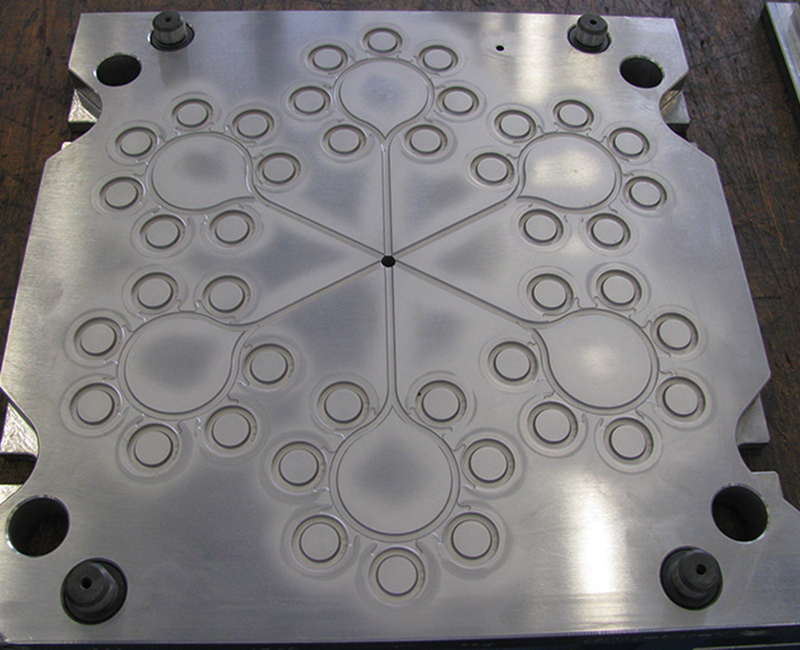

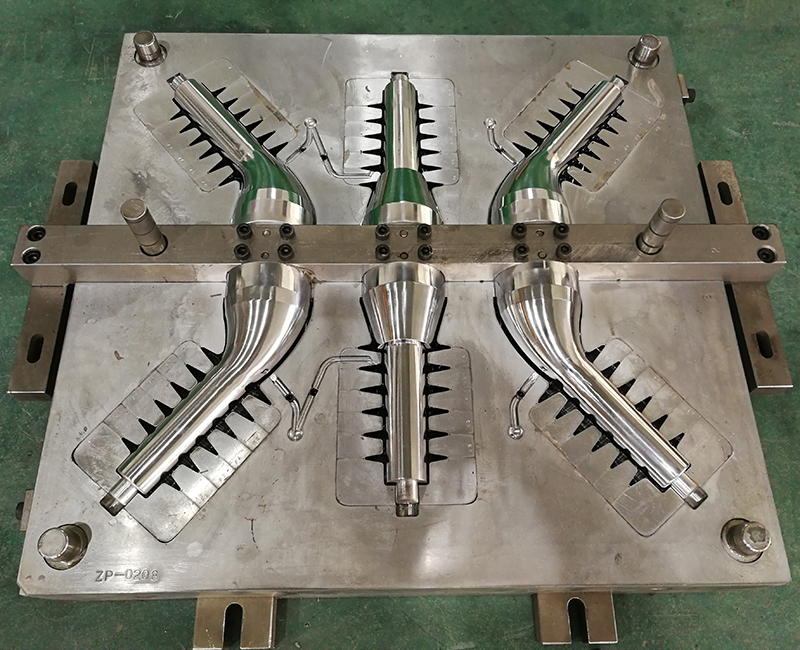

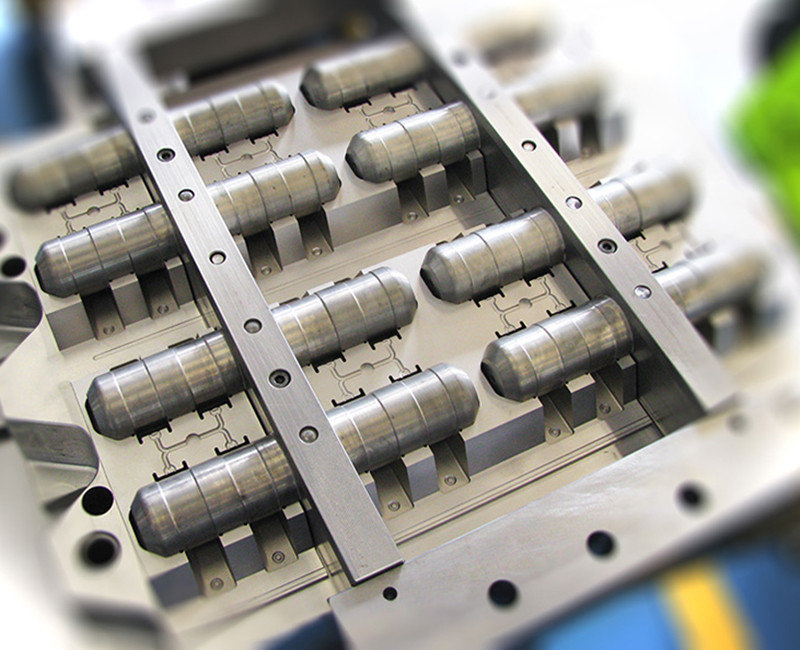

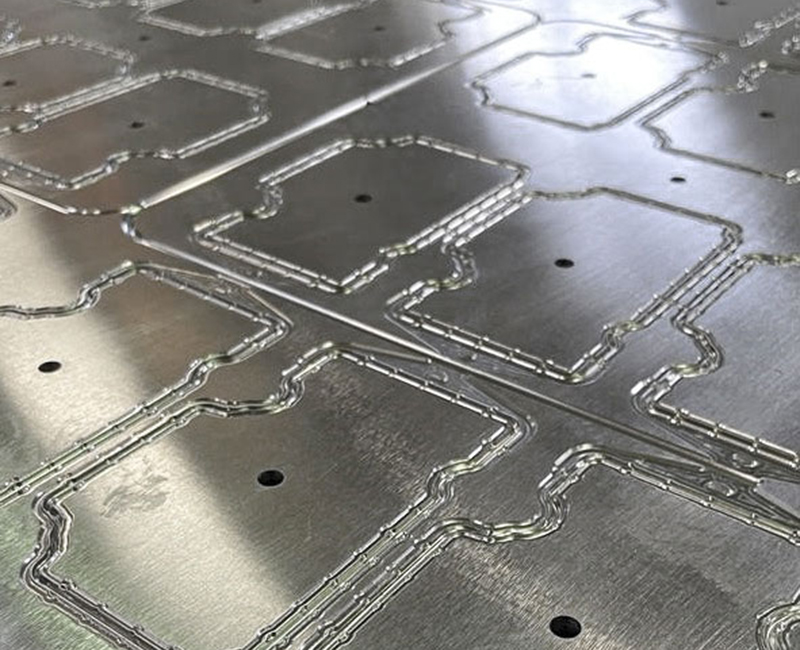

Rubber Mold suppliers or makers take the required specifications from their customers and produce a rubber silicone mold. This rubber or silicone mold is then provided to the rubber silicone injection molding company to manufacture the parts.

If the rubber part produced is not designed with the correct materials, final rubber products can fail in testing or in consumer’s hands. This quickly leads to disagreements between mold makers and rubber silicone injection machine factory about what part of the production process went wrong.

Commonly enough, failure of rubber injection molded parts is not an issue of bad practice on anyone’s part, but rather due to a reliance on cheap, low-durability materials in order to obtain a lower cost mold.

For quality rubber parts with the appropriate durability, manufacturers need to invest appropriately.

Enter the Rubber Injection Moulding Turnkey Solution Manufacturer

“How do we know who is to blame when a part goes bad?” is the wrong question. Instead, manufacturers need to ask who can complete a project start to finish all in-house, eliminating the middle man. This simplifies the process and provides a more reliable assurance of quality.

The answer to this question is a “turnkey solution” and GOWIN is one such company.

Rubber Moulding Turnkey Solutions help their customers by providing advice on mold designs before the production process begins. This is beneficial, as tooling is often the most expensive part of the rubber injection molding process.

Working with the Rubber Injection Moulding Turkey Solution Manufacturer

Manufacturers can also call in turnkey suppliers like GOWIN during the design stages of their mold.

“Our best advice to manufacturers is to get your turnkey provider of choice involved as early as possible in the design process for the best value for your dollar,” said Victor Lee, president of GOWIN.

This kind of close communication between a customer and their supplier can lead to greater trust between partners. Subsequently, this means a more reliable business partnership and initiates conversation about the best material selection for the end user’s application.

“We give our customers information on potential materials because they are the ones who understand what their product is exposed to in the end use,” Victor Lee explained. “We can give advice on designing parts, help them find ways to save money on the tool, give them suggestions on the thousands of materials they could use and the variations of their fillers and everything they put into those materials.”

Temperatures and chemicals that products may come in contact with are extremely important in material selection, for example.

“Every rubber or silicone has its strengths and weaknesses,” Victor Lee explained. “We need as much information as we can get to be as much help to our customers as possible.”