Adhering into the basic principle of “quality, assistance, effectiveness and growth”, we have attained trusts and praises from domestic and worldwide client for Manufacturing Companies for Plastic Injection Molding Processing Multi-Style Models Nylon Non-Standard Parts Special-Shaped Parts Support Mold Making, We warmly welcome customers from all over the world for any kind of cooperation with us to build a mutual benefit future. We are devoting ourselves wholeheartedly to offer customers the best service.

Adhering into the basic principle of “quality, assistance, effectiveness and growth”, we have attained trusts and praises from domestic and worldwide client for Customized Part and Auto Parts, Our company always concentrate on the development of the international market. We’ve a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

Main Features

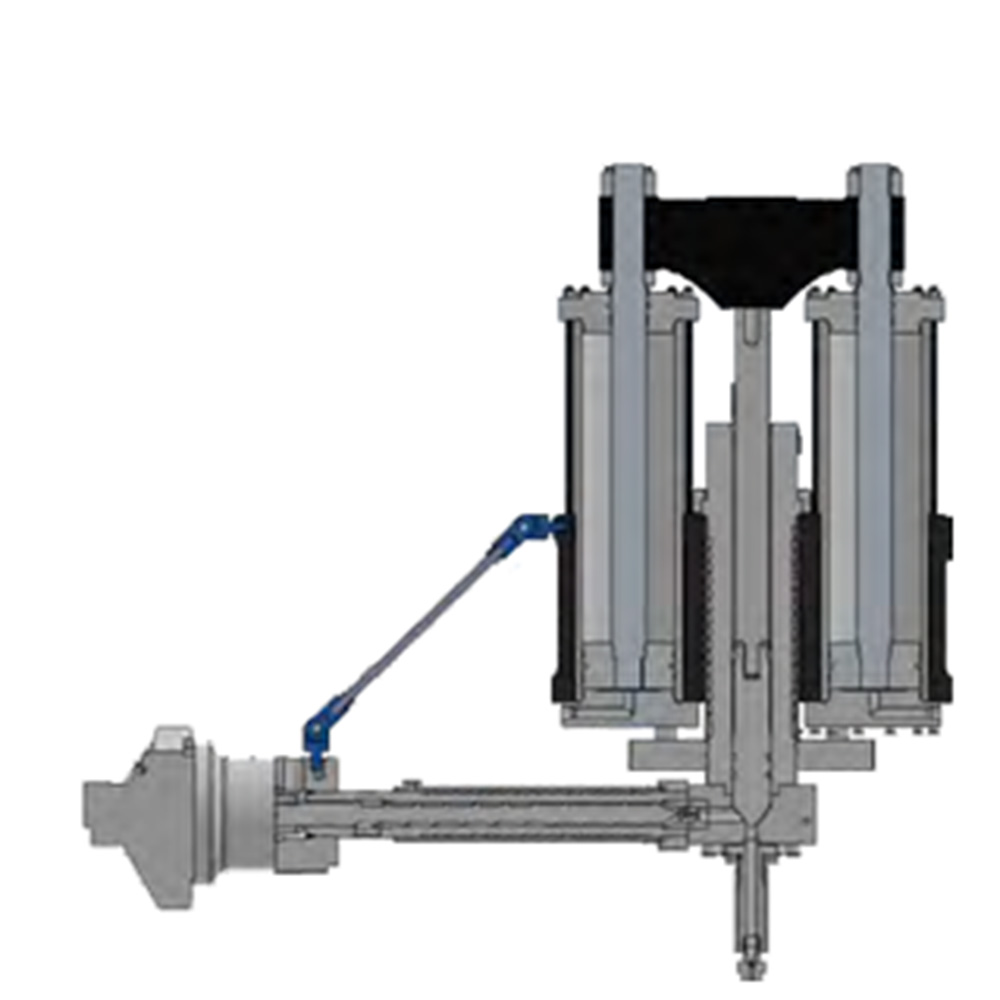

GW-RL Series Vertical Rubber Injection Machine are the most hot-selling & widely used GOWIN Rubber Injection Molding Machine models. The machines are equipped with VERTICAL CLAMPING SYSTEM & F.I.L.O. VERTICAL INJECTION SYSTEM, suitable for most rubber molded products in the fields of automobile, energy, railway transportation, industry, medical care and household appliances etc. And the Rubber Molding Machine is suitable for various of rubber compounds such as NR, NBR, EPDM, SBR, HNBR, FKM, SILICONE, ACM, AEM, etc.

The Rubber Molding Machine greatly improves production efficiency and reduces labor costs compared to traditional compression presses. It is an idea of Rubber Moulding Machine Models involving automation / semi-automation rubber molding. Also, the Rubber Machine is available for HOT RUNNER MOLD & COLD RUNNER BLOCK SYSTEM MOLD (optional solutions for CRB mold).

We GOWIN are expert for rubber machinery & rubber moulding solutions. Do not hesitate to contact us.

GW-RL Main Specification

|

Model |

GW-R120L |

GW-R160L |

GW-R250L |

GW-R300L |

GW-R350L |

GW-R400L |

|||||

|

Clamping Force(KN) |

1200 |

1600 |

2500 |

3000 |

3500 |

4000 |

|||||

|

Mold Open Stroke(mm) |

450 |

500 |

500 |

500 |

500 |

600 |

|||||

|

Platen Size(mm) |

430×500 |

500×500 |

560×630 |

600×700/600×800 |

700×800 |

700×800 |

|||||

|

Injection Volume(c.c) |

1000 |

1000 |

1000 |

2000 |

3000 |

3000 |

5000 |

3000 |

5000 |

5000 |

8000 |

|

Injection Force(bar) |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

| Model | GW-R550L | GW-R650L | GW-R800L | GW-R1200L | ||||

| Clamping Force(KN) | 5500 | 6500 | 8000 | 12000 | ||||

| Mold Open Stroke(mm) | 600 | 700 | 700 | 800 | ||||

| Platen Size(mm) | 850×1000 | 950×1000 | 950×1000 | 1200×1300 | ||||

| Injection Volume(c.c) | 5000 | 8000 | 5000 | 8000 | 8000 | 12000 | 12000 | 15000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

Packing & Shipping

|

Container |

GW-R120L |

GW-R160L |

GW-R250L |

GW-R300L |

GW-R400L |

|

20GP |

1 unit |

1 unit |

1 unit |

– |

- |

|

40HQ |

3 units |

3 units |

2 units |

2 units |

2 units |

|

Packing |

Package 1: Rubber Injection Machine Main Body |

||||

|

Package 2: Rubber Injection Machine Injection Unit |

|||||

|

Container |

GW-R550L |

GW-R650L |

GW-R800L |

GW-R1200L |

|

20GP |

– |

– |

– |

1 unit (one 40HQ + one 20GP) |

|

40HQ |

1 unit |

1 unit |

1 unit |

|

|

Packing |

Package 1: Vertical Rubber Injection Moulding Machine Main Body |

|||

|

Package 2: Vertical Rubber Injection Moulding Machine Injection Unit |

||||

Main Features

● Fixed-cylinder Vertical Injection

● High-pressure & High-precision Injection

● Modular-design & Multiple-combinations Solutions

● Low- bed & Optimized Structure

● Humanized Operating System

● High-efficiency & High-stability Hydraulic System

Injection System

● F.I.L.O. Injection System, low rubber feeding height.

● Two-Fixed Cylinder for injection, steady injection and high injection accuracy & stability

● Injection Unit center of gravity in bottom which lead to more steady operation.

● Excellent Oil Cooling System for SCREW & BARREL ensuring WHOLE RUBBER CHANCEL under accuracy temperature control to get better fluency of rubber compound.

● Injection Unit available to move up & down, more convenient for daily operation and maintenance.

Adhering into the basic principle of “quality, assistance, effectiveness and growth”, we have attained trusts and praises from domestic and worldwide client for Manufacturing Companies for Plastic Injection Molding Processing Multi-Style Models Nylon Non-Standard Parts Special-Shaped Parts Support Mold Making, We warmly welcome customers from all over the world for any kind of cooperation with us to build a mutual benefit future. We are devoting ourselves wholeheartedly to offer customers the best service.

Manufacturing Companies for Customized Part and Auto Parts, Our company always concentrate on the development of the international market. We’ve a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.