We not only will try our best to offer superb solutions to every single shopper, but also are ready to receive any suggestion offered by our prospects for IOS Certificate Press Rubber Knurling Steel Roller Customize Mould Spare Parts Milling Grinding Machining, We consider excellent as the foundation of our results. Thus, we focus on the manufacture of your best high quality items. A strict excellent management system has been created to make sure the standard of the items.

We not only will try our best to offer superb solutions to every single shopper, but also are ready to receive any suggestion offered by our prospects for China Injection Mould and Plastic Mould, We have a dedicated and aggressive sales team, and many branches, catering to our main customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

Main Features

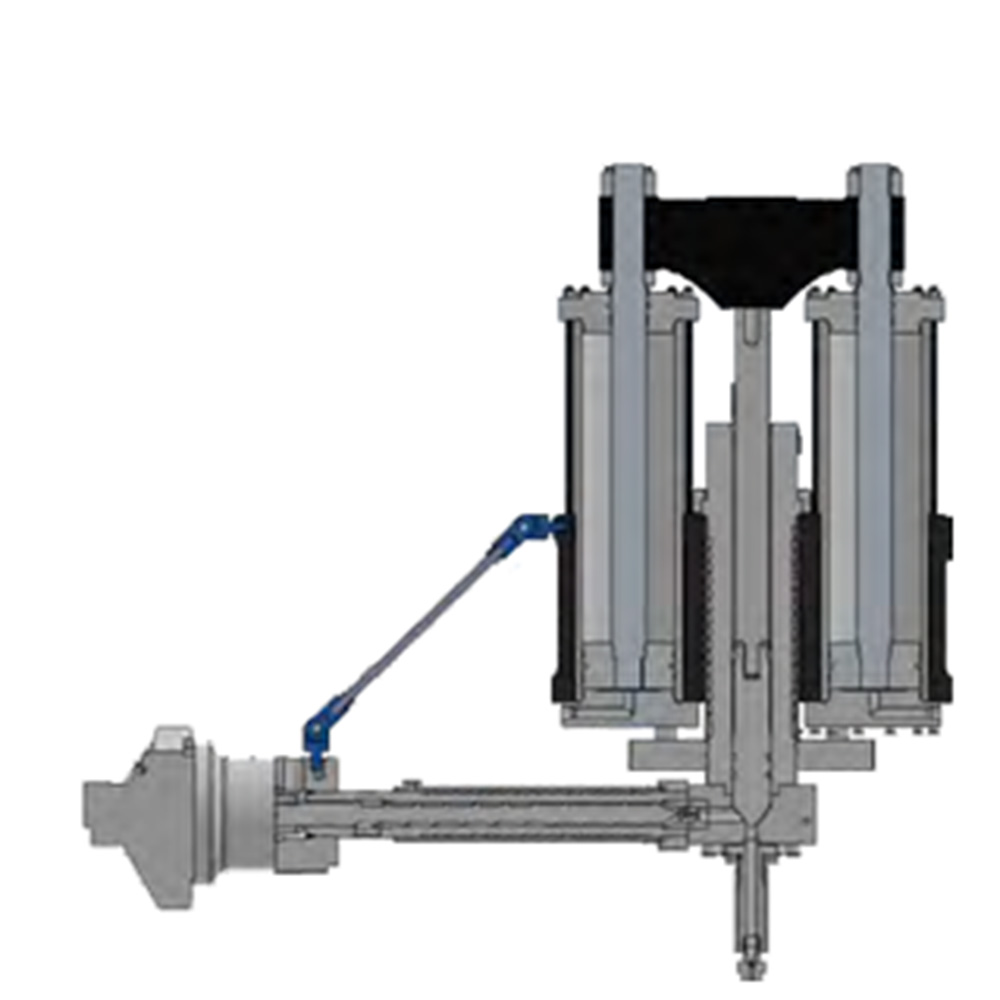

GW-RL Series Vertical Rubber Injection Machine are the most hot-selling & widely used GOWIN Rubber Injection Molding Machine models. The machines are equipped with VERTICAL CLAMPING SYSTEM & F.I.L.O. VERTICAL INJECTION SYSTEM, suitable for most rubber molded products in the fields of automobile, energy, railway transportation, industry, medical care and household appliances etc. And the Rubber Molding Machine is suitable for various of rubber compounds such as NR, NBR, EPDM, SBR, HNBR, FKM, SILICONE, ACM, AEM, etc.

The Rubber Molding Machine greatly improves production efficiency and reduces labor costs compared to traditional compression presses. It is an idea of Rubber Moulding Machine Models involving automation / semi-automation rubber molding. Also, the Rubber Machine is available for HOT RUNNER MOLD & COLD RUNNER BLOCK SYSTEM MOLD (optional solutions for CRB mold).

We GOWIN are expert for rubber machinery & rubber moulding solutions. Do not hesitate to contact us.

GW-RL Main Specification

|

Model |

GW-R120L |

GW-R160L |

GW-R250L |

GW-R300L |

GW-R350L |

GW-R400L |

|||||

|

Clamping Force(KN) |

1200 |

1600 |

2500 |

3000 |

3500 |

4000 |

|||||

|

Mold Open Stroke(mm) |

450 |

500 |

500 |

500 |

500 |

600 |

|||||

|

Platen Size(mm) |

430×500 |

500×500 |

560×630 |

600×700/600×800 |

700×800 |

700×800 |

|||||

|

Injection Volume(c.c) |

1000 |

1000 |

1000 |

2000 |

3000 |

3000 |

5000 |

3000 |

5000 |

5000 |

8000 |

|

Injection Force(bar) |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

| Model | GW-R550L | GW-R650L | GW-R800L | GW-R1200L | ||||

| Clamping Force(KN) | 5500 | 6500 | 8000 | 12000 | ||||

| Mold Open Stroke(mm) | 600 | 700 | 700 | 800 | ||||

| Platen Size(mm) | 850×1000 | 950×1000 | 950×1000 | 1200×1300 | ||||

| Injection Volume(c.c) | 5000 | 8000 | 5000 | 8000 | 8000 | 12000 | 12000 | 15000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

Packing & Shipping

|

Container |

GW-R120L |

GW-R160L |

GW-R250L |

GW-R300L |

GW-R400L |

|

20GP |

1 unit |

1 unit |

1 unit |

– |

- |

|

40HQ |

3 units |

3 units |

2 units |

2 units |

2 units |

|

Packing |

Package 1: Rubber Injection Machine Main Body |

||||

|

Package 2: Rubber Injection Machine Injection Unit |

|||||

|

Container |

GW-R550L |

GW-R650L |

GW-R800L |

GW-R1200L |

|

20GP |

– |

– |

– |

1 unit (one 40HQ + one 20GP) |

|

40HQ |

1 unit |

1 unit |

1 unit |

|

|

Packing |

Package 1: Vertical Rubber Injection Moulding Machine Main Body |

|||

|

Package 2: Vertical Rubber Injection Moulding Machine Injection Unit |

||||

Main Features

● Fixed-cylinder Vertical Injection

● High-pressure & High-precision Injection

● Modular-design & Multiple-combinations Solutions

● Low- bed & Optimized Structure

● Humanized Operating System

● High-efficiency & High-stability Hydraulic System

Injection System

● F.I.L.O. Injection System, low rubber feeding height.

● Two-Fixed Cylinder for injection, steady injection and high injection accuracy & stability

● Injection Unit center of gravity in bottom which lead to more steady operation.

● Excellent Oil Cooling System for SCREW & BARREL ensuring WHOLE RUBBER CHANCEL under accuracy temperature control to get better fluency of rubber compound.

● Injection Unit available to move up & down, more convenient for daily operation and maintenance.

We not only will try our best to offer superb solutions to every single shopper, but also are ready to receive any suggestion offered by our prospects for IOS Certificate Press Rubber Knurling Steel Roller Customize Mould Spare Parts Milling Grinding Machining, We consider excellent as the foundation of our results. Thus, we focus on the manufacture of your best high quality items. A strict excellent management system has been created to make sure the standard of the items.

IOS Certificate China Injection Mould and Plastic Mould, We have a dedicated and aggressive sales team, and many branches, catering to our main customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

-

Best-Selling Plastic Shock Absorber Boot Rubber...

-

Factory Injection Moulding POM Material Inner D...

-

Silicone Injection Moulding Machine: unlock the...

-

High reputation Automotive Parts Grille Injecti...

-

Factory Rubber Mat Making Machine, Rubber Plate...

-

Excellent quality Cost-Effective Plastic Inject...