We support our customers with ideal premium quality products and solutions and superior level assistance. Becoming the specialist manufacturer in this sector, now we have received rich practical experience in producing and managing for Hot sale Jaw Structure and Pillar Structure Mini Silicone Rubber Injection Seal Roller Moulding Curing Press Machine (XLB-350*350/XLB-400*400), Our company quickly grew in size and reputation because of its absolute dedication to high quality manufacturing, high value of products and excellent customer service.

We support our customers with ideal premium quality products and solutions and superior level assistance. Becoming the specialist manufacturer in this sector, now we have received rich practical experience in producing and managing for China Rubber Injection Molding Machine and Rubber Injection Moulding Machine, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. We also supply agency service—that act as the agent in china for our customers. If you are interested in any of our goods or have an OEM order to fulfill, make sure you feel free to contact us now. Working with us will save you money and time.

Description

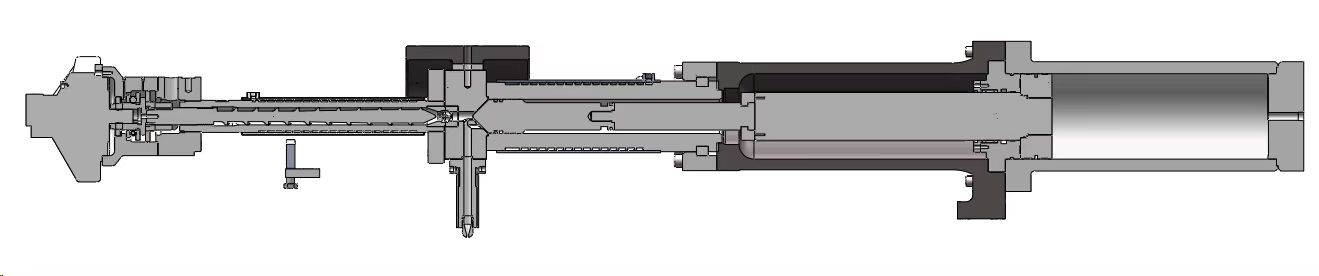

The GW-SL Series Rubber Injection Molding Machine with VERTICAL CLAMPING SYSTEM & F.I.L.O. Angle-Type INJECTION SYSTEM is one of the MOST POPULAR Rubber Molding Machine in the market. The Moulding Press Single-Fixed-Cylinder Injection Unit, horizontally mounting on the top platen which reduces overall rubber Press height a lot. This rubber press model is suitable for customers who have limited-height workshops.

Also, the Rubber Molding Machine is suitable for most rubber molded products in the fields of automobile, energy, railway transportation, industry, medical care and household appliances, etc. The Molding Machine is suitable for various rubber compounds such as NR, NBR, EPDM, SBR, HNBR, FKM, SILICONE, ACM, AEM, etc.

The Rubber Injection Moulding Machine greatly improves production efficiency and reduces labor costs compared with traditional compression press.

GW-SL Main Specification

| Model | GW-S120L | GW-S160L | GW-S250L | GW-S300L | GW-S400L | ||||

| Clamping Force(KN) | 1200 | 1600 | 2500 | 3000 | 4000 | ||||

| Mold Open Stroke(mm) | 450 | 500 | 500 | 500 | 600 | ||||

| Platen Size(mm) | 430×500 | 500×500 | 560×630 | 600×700/600×800 | 700×800 | ||||

| Injection Volume(c.c) | 1000 | 1000 | 1000 | 2000 | 3000 | 3000 | 5000 | 5000 | 8000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

| Model | GW-S550L | GW-S650L | GW-S800L | GW-S1200L | ||||

| Clamping Force(KN) | 5500 | 6500 | 8000 | 12000 | ||||

| Mold Open Stroke(mm) | 600 | 700 | 700 | 800 | ||||

| Platen Size(mm) | 850×1000 | 950×1000 | 950×1000 | 1200×1300 | ||||

| Injection Volume(c.c) | 5000 | 8000 | 5000 | 8000 | 8000 | 12000 | 12000 | 15000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

Packing & Shipping

|

Container |

GW-S120L |

GW-S160L |

GW-S250L |

GW-S300L |

GW-S400L |

|

20GP |

1 unit |

1 unit |

1 unit |

– |

- |

|

40HQ |

3 units |

3 units |

2 units |

2 units |

2 units |

|

Packing |

Package 1: Rubber Injection Moulding Machine Main Body; |

||||

|

Package 2: Rubber Injection Moulding Machine Injection Unit |

|||||

|

Container |

GW-S550L |

GW-S650L |

GW-S800L |

GW-S1200L |

|

20GP |

– |

– |

– |

1 unit (one 40HQ + one 20GP) |

|

40HQ |

1 unit |

1 unit |

1 unit |

|

|

Packing |

Package 1: Injection Moulding Machine Main Body; |

|||

|

Package 2: Injection Moulding Machine Injection Unit |

||||

Main Features

● Vertical Clamping Unit & Angle-type Injection Unit

● High-pressure & High-precision Injection

● Modular-design & Multiple-combinations Solution

● Low Overall Height

● Humanized Operating System

● High-efficiency & High-stability Hydraulic System

Injection System

● 1. F.I.L.O. Injection System, low rubber feeding height.

● 2. Single-Fixed-Cylinder Injection Unit, Horizontally Mounting On The Top Platen.

● 3. Steady Injection and High Injection accuracy & stability

● 4. Excellent Oil Cooling System for SCREW & BARREL ensuring good performance of rubber compound.

We support our customers with ideal premium quality products and solutions and superior level assistance. Becoming the specialist manufacturer in this sector, now we have received rich practical experience in producing and managing for Hot sale Jaw Structure and Pillar Structure Mini Silicone Rubber Injection Seal Roller Moulding Curing Press Machine (XLB-350*350/XLB-400*400), Our company quickly grew in size and reputation because of its absolute dedication to high quality manufacturing, high value of products and excellent customer service.

Hot sale China Rubber Injection Molding Machine and Rubber Injection Moulding Machine, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. We also supply agency service—that act as the agent in china for our customers. If you are interested in any of our goods or have an OEM order to fulfill, make sure you feel free to contact us now. Working with us will save you money and time.

-

18 Years Factory Rubber Foam Product Making Mac...

-

OEM/ODM Manufacturer Custom Thermoset Piece Sil...

-

Factory Quality Plastic Injection Mould Manufac...

-

Competitive Price for Automatic Big Injection M...

-

Personlized Products Automatic Rubber Molding M...

-

Top Grade Interleave Overlap Bag Winding Techno...