No matter new consumer or outdated shopper, We believe in lengthy expression and trusted relationship for High reputation Automotive Parts Grille Injection Toolings Molding Mold, As an experienced group we also accept tailored orders. The main aim of our corporation is always to develop a satisfying memory for all shoppers, and set up a long-term win-win business partnership.

No matter new consumer or outdated shopper, We believe in lengthy expression and trusted relationship for Mould and Mold, Our skilled engineering group will always be ready to serve you for consultation and feedback. We are able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to offer you the ideal service and items. For anyone who is thinking about our company and merchandise, remember to contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We are going to always welcome guests from all over the world to our business to build company relations with us. Remember to feel free to get in touch with us for business and we believe we’ve been going to share the top trading practical experience with all our merchants.

Description

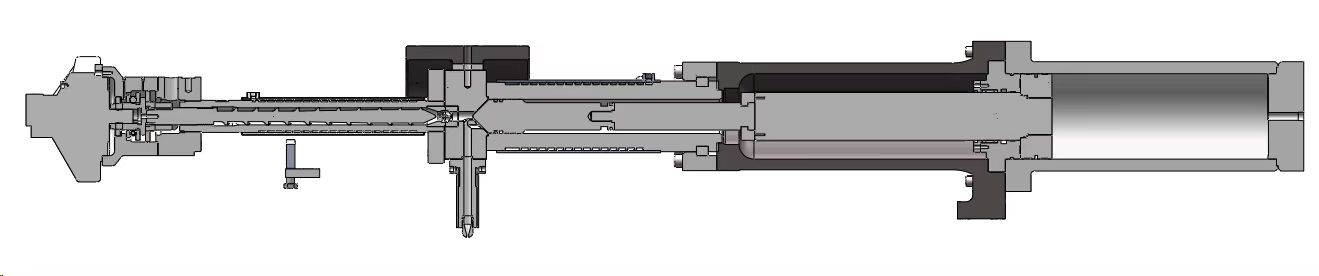

The GW-SL Series Rubber Injection Molding Machine with VERTICAL CLAMPING SYSTEM & F.I.L.O. Angle-Type INJECTION SYSTEM is one of the MOST POPULAR Rubber Molding Machine in the market. The Moulding Press Single-Fixed-Cylinder Injection Unit, horizontally mounting on the top platen which reduces overall rubber Press height a lot. This rubber press model is suitable for customers who have limited-height workshops.

Also, the Rubber Molding Machine is suitable for most rubber molded products in the fields of automobile, energy, railway transportation, industry, medical care and household appliances, etc. The Molding Machine is suitable for various rubber compounds such as NR, NBR, EPDM, SBR, HNBR, FKM, SILICONE, ACM, AEM, etc.

The Rubber Injection Moulding Machine greatly improves production efficiency and reduces labor costs compared with traditional compression press.

GW-SL Main Specification

| Model | GW-S120L | GW-S160L | GW-S250L | GW-S300L | GW-S400L | ||||

| Clamping Force(KN) | 1200 | 1600 | 2500 | 3000 | 4000 | ||||

| Mold Open Stroke(mm) | 450 | 500 | 500 | 500 | 600 | ||||

| Platen Size(mm) | 430×500 | 500×500 | 560×630 | 600×700/600×800 | 700×800 | ||||

| Injection Volume(c.c) | 1000 | 1000 | 1000 | 2000 | 3000 | 3000 | 5000 | 5000 | 8000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

| Model | GW-S550L | GW-S650L | GW-S800L | GW-S1200L | ||||

| Clamping Force(KN) | 5500 | 6500 | 8000 | 12000 | ||||

| Mold Open Stroke(mm) | 600 | 700 | 700 | 800 | ||||

| Platen Size(mm) | 850×1000 | 950×1000 | 950×1000 | 1200×1300 | ||||

| Injection Volume(c.c) | 5000 | 8000 | 5000 | 8000 | 8000 | 12000 | 12000 | 15000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

Packing & Shipping

|

Container |

GW-S120L |

GW-S160L |

GW-S250L |

GW-S300L |

GW-S400L |

|

20GP |

1 unit |

1 unit |

1 unit |

– |

- |

|

40HQ |

3 units |

3 units |

2 units |

2 units |

2 units |

|

Packing |

Package 1: Rubber Injection Moulding Machine Main Body; |

||||

|

Package 2: Rubber Injection Moulding Machine Injection Unit |

|||||

|

Container |

GW-S550L |

GW-S650L |

GW-S800L |

GW-S1200L |

|

20GP |

– |

– |

– |

1 unit (one 40HQ + one 20GP) |

|

40HQ |

1 unit |

1 unit |

1 unit |

|

|

Packing |

Package 1: Injection Moulding Machine Main Body; |

|||

|

Package 2: Injection Moulding Machine Injection Unit |

||||

Main Features

● Vertical Clamping Unit & Angle-type Injection Unit

● High-pressure & High-precision Injection

● Modular-design & Multiple-combinations Solution

● Low Overall Height

● Humanized Operating System

● High-efficiency & High-stability Hydraulic System

Injection System

● 1. F.I.L.O. Injection System, low rubber feeding height.

● 2. Single-Fixed-Cylinder Injection Unit, Horizontally Mounting On The Top Platen.

● 3. Steady Injection and High Injection accuracy & stability

● 4. Excellent Oil Cooling System for SCREW & BARREL ensuring good performance of rubber compound.

No matter new consumer or outdated shopper, We believe in lengthy expression and trusted relationship for High reputation Automotive Parts Grille Injection Toolings Molding Mold, As an experienced group we also accept tailored orders. The main aim of our corporation is always to develop a satisfying memory for all shoppers, and set up a long-term win-win business partnership.

High reputation Mould and Mold, Our skilled engineering group will always be ready to serve you for consultation and feedback. We are able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to offer you the ideal service and items. For anyone who is thinking about our company and merchandise, remember to contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We are going to always welcome guests from all over the world to our business to build company relations with us. Remember to feel free to get in touch with us for business and we believe we’ve been going to share the top trading practical experience with all our merchants.