We’re going to devote ourselves to offering our esteemed shoppers with the most enthusiastically thoughtful expert services for High Quality Rubber Conveyor Belt Vulcanizing Machine with CE and ISO, We have experienced manufacturing facilities with more than 100 employees. So we can guarantee short lead time and quality assurance.

We’re going to devote ourselves to offering our esteemed shoppers with the most enthusiastically thoughtful expert services for China Vulcanizing Machine and Conveyor Belt Vulcanizing Machine, Ensuring high product quality by choosing the best suppliers, we now have also implemented thorough quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

Description

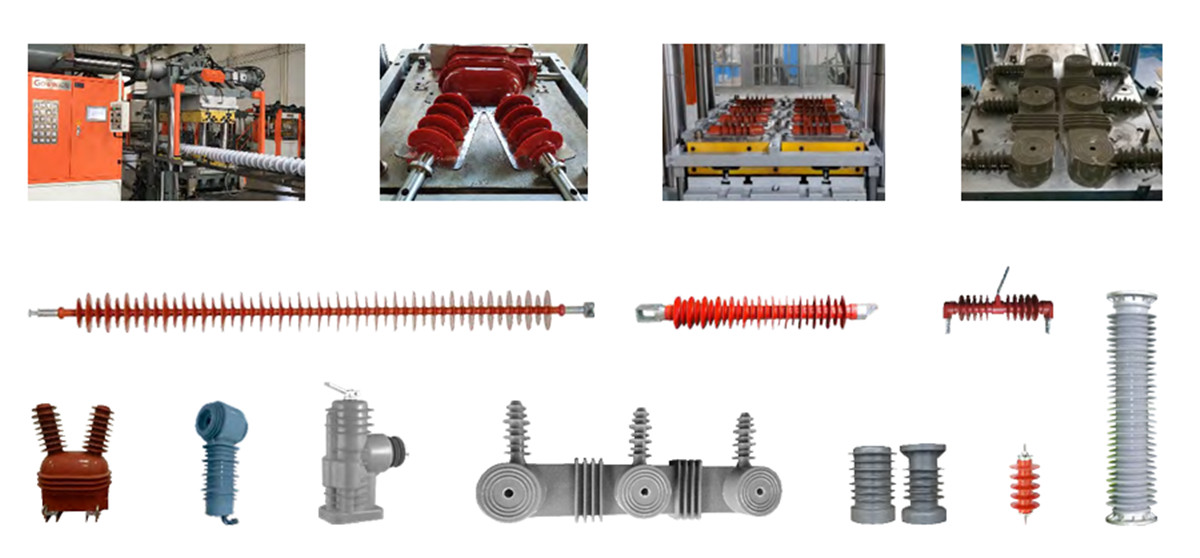

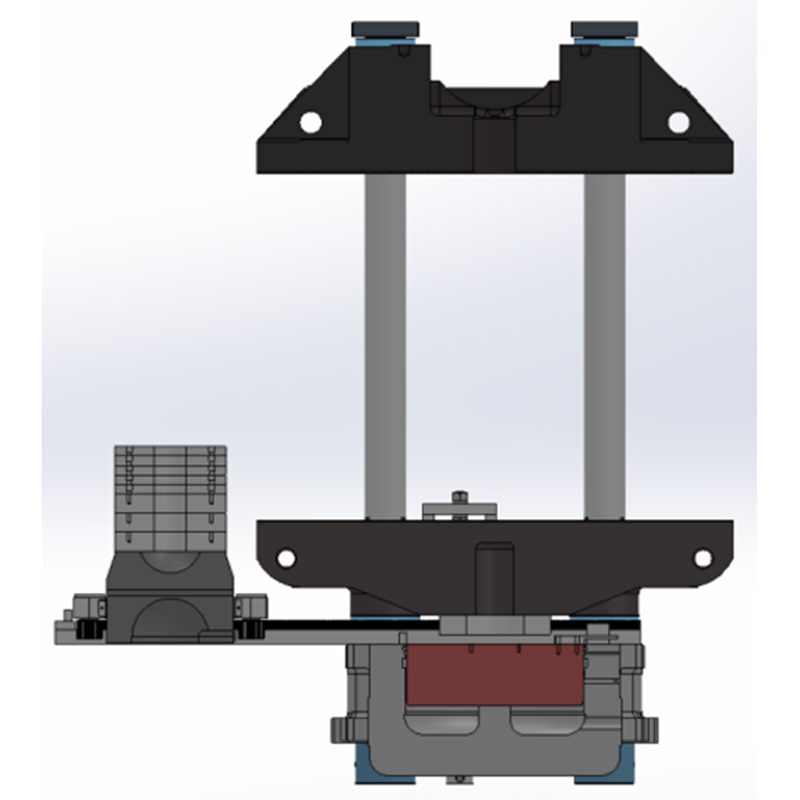

GOWIN GW-SL Series Solid Silicone Injection Moulding Machine for Energy Industry is one of the most hot-selling & star model among GOWIN Rubber Injection Machine models. The silicone rubber molding machines are equipped with VERTICAL CLAMPING SYSTEM & F.I.L.O. HORIZONTAL INJECTION SYSTEM & Large Capacity Silicone Stuffer, which are special designed models for Polymer Insulator, Arrester, Cable Accessories etc. It is ideal model for large component of silicone rubber mouldings.

The Insulator Making Machine is greatly improving production efficiency and reducing labor costs. The Silicone Injection Machine are available for HOT RUNNER MOLD & COLD RUNNER BLOCK SYSTEM MOLD.

With over 16 years sufficient experience in the field of power transmission & distribution, GOWIN has exported many Silicone Insulator Molding Machines to many countries such Korea, Russia, India, Egypt, Ukraine, Indonesia, Thailand, Malaysia, Vietnam etc. GOWIN are providing turn-key solutions for insulator molding including factory layout suggestion, insulator moulding machine, Insulator Mold, Crimping Machine, Tension Testing Machine, Electrical Testing Equipment, Rubber Material, Production Training etc.

Solid Silicone Injection Series Main Specification

|

Model |

GW-S160L |

GW-S250L |

GW-S300L |

GW-S360L |

GW-S400L |

GW-S550L |

|

|

Clamping Force(KN) |

1600 |

2500 |

3000 |

3600 |

4000 |

5500 |

|

|

Mold Open Stroke(mm) |

500 |

500 |

500 |

500 |

600 |

600 |

|

|

Platen Size(mm) |

500×630 |

600×800 |

600×800/630×1000 |

630×1300 |

750×800 |

630×1700/630×1500/800×1000 |

|

|

Injection Volume(c.c) |

3000 |

3000 |

5000 |

6000 |

6000/8000 |

6000/8000 |

13000/15000 |

|

Injection Force(bar) |

1375 |

1375 |

1375 |

1260 |

1260 |

1260 |

1260 |

|

Model |

GW-S650L |

GW-S1000L |

GW-S1100L |

GW-S1800L |

|

Clamping Force(KN) |

6500 |

10000 |

11000 |

18000 |

|

Mold Open Stroke(mm) |

700 |

800 |

700 |

1200 |

|

Platen Size(mm) |

800×1700/950×1700 |

1000×1800 |

800×2600 |

1000×2600 |

|

Injection Volume(c.c) |

15000/20000/25000 |

25000/32000 |

25000/32000 |

50000/60000 |

|

Injection Force(bar) |

1260 |

1260 |

1260 |

1260 |

Packing & Shipping

|

Container |

GW-S160L |

GW-S250L |

GW-S300L |

GW-S360L |

GW- S400L |

|

20GP |

1 unit |

– |

– |

– |

- |

|

40HQ |

3 units |

2 units |

2 units |

2 units |

2 units |

|

Packing |

Package 1: Rubber Injection Moulding Machine Main Body |

||||

|

Package 2: Rubber Injection Moulding Machine Silicone Stuffer |

|||||

|

Container |

GW- S550L |

GW- S650L |

GW- S1000L |

GW-S1100L |

GW-S1800L |

|

20GP |

– |

– |

1 unit (two 40HQ) |

1 unit (two 40HQ) |

1 unit (two 40HQ + one 20GP) |

|

40HQ |

1 unit |

1 unit |

|||

|

Packing |

Package 1: Rubber Injection Molding Machine Main Body; |

||||

|

Package 2: Rubber Injection Molding Machine Injection Unit; |

|||||

|

Package 3: Rubber Injection Molding Machine Guarding |

|||||

Main Features

● Specialized Design for Solid Silicone Product Molding in Energy Industry, such as for Polymer Insulator, Polymer Fuse Cut-out, Polymer Transformer etc.

● Specialized Designed Angle-type Injection System for Solid Silicone.

● Reasonable Machine Layout, Convenient for Operation in All Access.

● Strong Enough Mechanical Structure to Ensure Stable Molding Quality

● Large Enough Silicone Stuffer On Floor.

Injection System

● GOWIN Patent “Three-Step Mold Close System” (for big Ton Machine Models).

● Low Operation Height, Convenient & Safe.

● Strong Structure, Movement Steady.

We’re going to devote ourselves to offering our esteemed shoppers with the most enthusiastically thoughtful expert services for High Quality Rubber Conveyor Belt Vulcanizing Machine with CE and ISO, We have experienced manufacturing facilities with more than 100 employees. So we can guarantee short lead time and quality assurance.

High Quality China Vulcanizing Machine and Conveyor Belt Vulcanizing Machine, Ensuring high product quality by choosing the best suppliers, we now have also implemented thorough quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.