“Sincerity, Innovation, Rigorousness, and Efficiency” could be the persistent conception of our organization for that long-term to produce with each other with buyers for mutual reciprocity and mutual gain for High Quality for Automatic Horizontal Rubber Injection Moulding Machine for Rubber&Silicone Products, Since establishment inside the early 1990s, we have now build our sale network in USA, Germany, Asia, and several Middle Eastern countries. We goal to get a top class supplier for around the globe OEM and aftermarket!

“Sincerity, Innovation, Rigorousness, and Efficiency” could be the persistent conception of our organization for that long-term to produce with each other with buyers for mutual reciprocity and mutual gain for China Horizontal Moulding Machine and Horizontal Rubber Injection Machine, Our company has always insisted on the business principle of “Quality, Honest, and Customer First” by which we have won the trust of clients both from at home and abroad. If you are interested in our products, please do not hesitate to contact us for further information.

Description

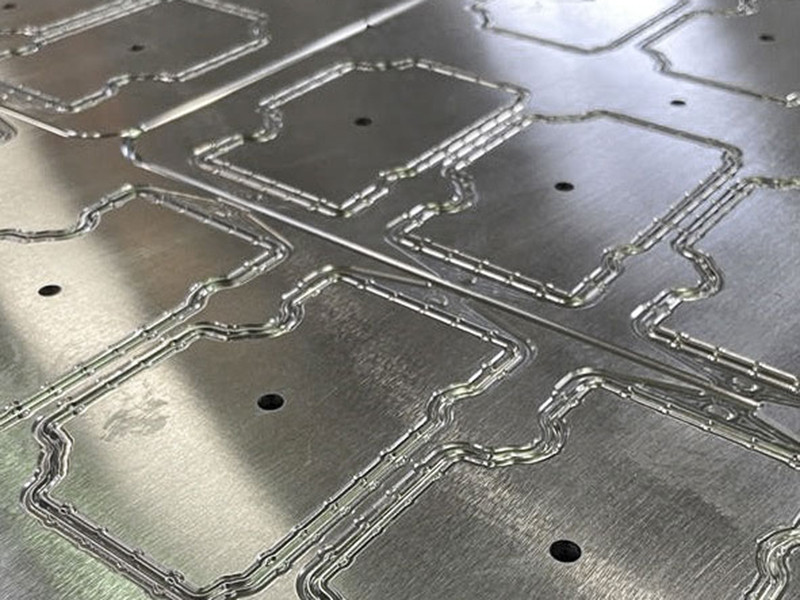

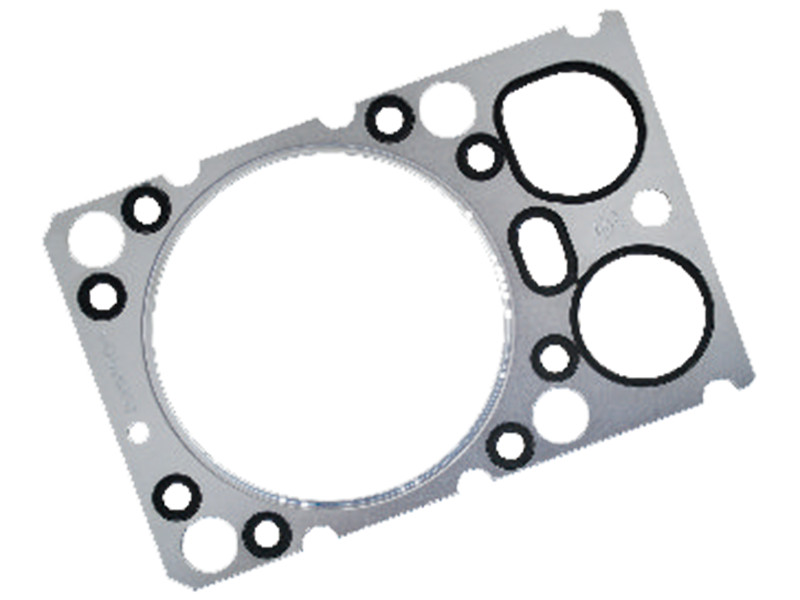

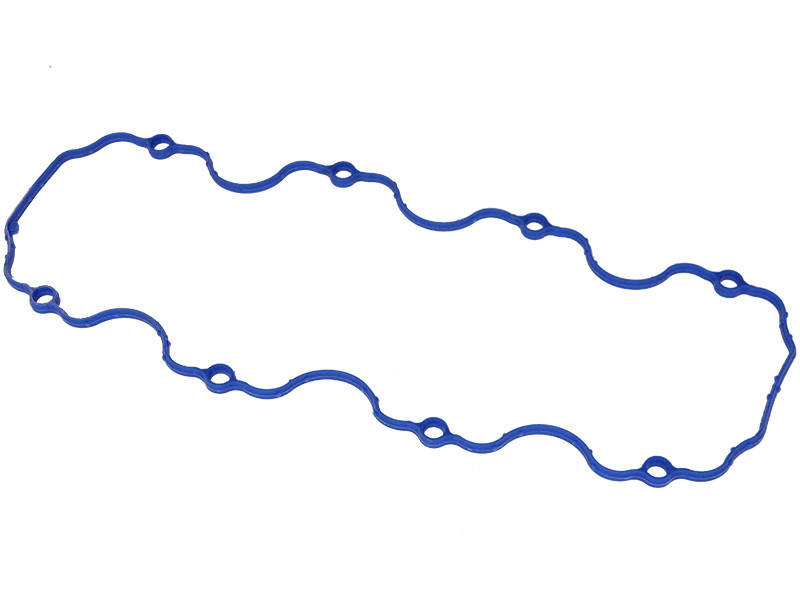

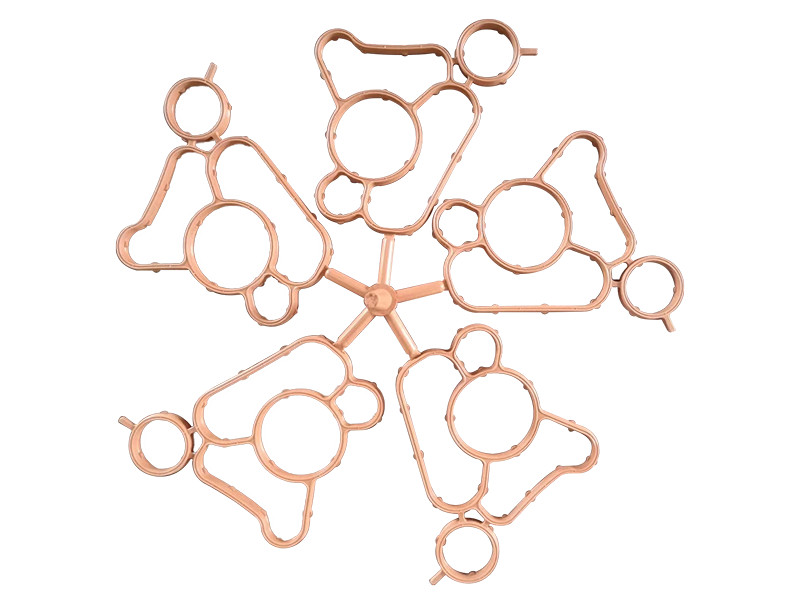

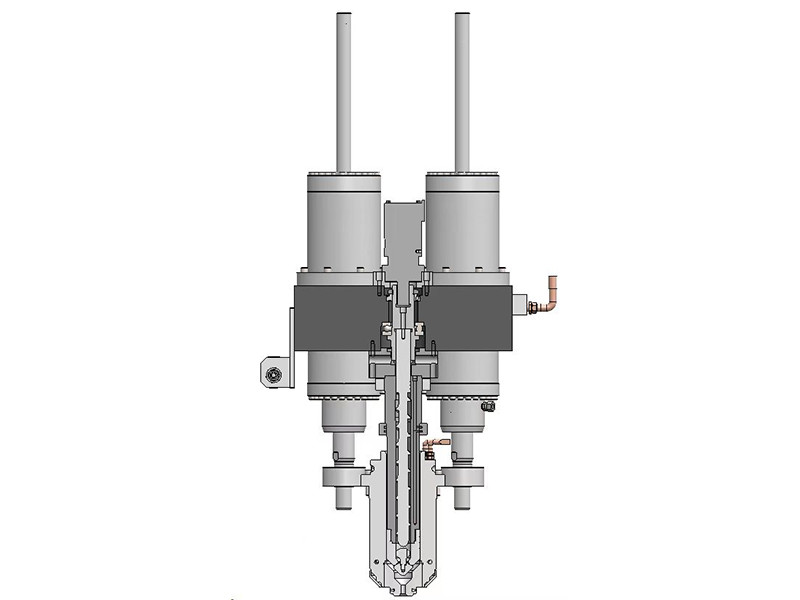

The GW-RF Series F.I.F.O Vertical Rubber Injection Moulding Machine are GOWIN High-End Rubber Moulding Machine Models. The machines are equipped with a VERTICAL CLAMPING SYSTEM & F.I.F.O. VERTICAL INJECTION SYSTEM, suitable for various rubber molded parts, especially precision rubber sealing products in the field of automobile, energy, railway transportation, industry, medical care and household appliances, etc.

With the High performance of the F.I.F.O. Injection System, the Rubber Moulding Machine is available to match all kinds of rubber moulding such as NR, NBR, EPDM, SBR, HNBR, FKM, SILICONE, ACM, AEM, etc.

With High-end SERVO SYSTEM, the Rubber Molding Machine is greatly improving production efficiency and reducing labor costs. It is an idea of Rubber Molding Machine Models involving automation rubber molding. Also, the Rubber Machine is available for HOT RUNNER MOLD & COLD RUNNER BLOCK SYSTEM MOLD (optional solutions for CRB mold).

GW-RF Main Specification

| Model | GW-R120F | GW-R160F | GW-R250F | GW-R300F | ||||

| Clamping Force(KN) | 1200 | 1600 | 2500 | 3000 | ||||

| Mold Open Stroke(mm) | 450 | 500 | 500 | 500 | ||||

| Platen Size(mm) | 430×500 | 500×500 | 560×630 | 600×700/600×800 | ||||

| Injection Volume(c.c) | 1000 | 1000 | 500 | 1000 | 2000 | 500 | 1000 | 2000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

| Model | GW-R400F | GW-R550F | GW-R650F | ||||||

| Clamping Force(KN) | 4000 | 5500 | 6500 | ||||||

| Mold Open Stroke(mm) | 600 | 600 | 700 | ||||||

| Platen Size(mm) | 700×800 | 850×1000 | 950×1000 | ||||||

| Injection Volume(c.c) | 1000 | 2000 | 3000 | 1000 | 2000 | 3000 | 1000 | 2000 | 3000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

Packing & Shipping

|

Container |

GW-R120F |

GW-R160F |

GW-R250F |

|

20GP |

1 unit |

1 unit |

1 unit |

|

40HQ |

3 units |

3 units |

2 units |

|

Packing |

Package 1: Rubber Machine Main Body; |

||

|

Package 2: Rubber Machine Injection Unit |

|||

|

Container |

GW-R550F |

GW-R650F |

|

20GP |

– |

– |

|

40HQ |

1 unit |

1 unit |

|

Packing |

Package 1: Molding Machine Main Body; |

|

|

Package 2: Molding Machine Injection Unit |

||

Main Features

● Precise Injection

● Modular-design & Multiple-combinations Solutions

● Low-bed & Optimized Structure

● Humanized Operating System

● High-efficiency &High-stability& High-Energy-Saving Servo Hydraulic System

Injection System

● F.I.F.O. Injection System, Moving-Cylinder Vertical Injection

● High-speed & High-pressure & High-precision Injection

● Short Injection Nozzle Design, Less injection pressure loss

● Available for Various Special Rubber Compound Such as VITON

“Sincerity, Innovation, Rigorousness, and Efficiency” could be the persistent conception of our organization for that long-term to produce with each other with buyers for mutual reciprocity and mutual gain for High Quality for Automatic Horizontal Rubber Injection Moulding Machine for Rubber&Silicone Products, Since establishment inside the early 1990s, we have now build our sale network in USA, Germany, Asia, and several Middle Eastern countries. We goal to get a top class supplier for around the globe OEM and aftermarket!

High Quality for China Horizontal Moulding Machine and Horizontal Rubber Injection Machine, Our company has always insisted on the business principle of “Quality, Honest, and Customer First” by which we have won the trust of clients both from at home and abroad. If you are interested in our products, please do not hesitate to contact us for further information.

-

ODM Polyurethane High Pressure PU Foam Machiner...

-

ODM Factory Newest Type High Pressure Polyureth...

-

High Quality Zhengyue Best Selling Compression ...

-

Hot Lock Flocking Silicone Coating Corrugated C...

-

High Performance High-Quality Plastic Mould Man...

-

China New Product Hot Runner Customized Injecti...