We provide fantastic energy in top quality and advancement,merchandising,gross sales and marketing and operation for High-Performance Rubber Making Machines for Precision and Efficiency, We guaranteed high-quality, if clients were not pleased together with the products’ good quality, you can return inside of 7days with their original states.

We provide fantastic energy in top quality and advancement,merchandising,gross sales and marketing and operation for Rubber processing machines, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we supply shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we’ve got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

Main Features

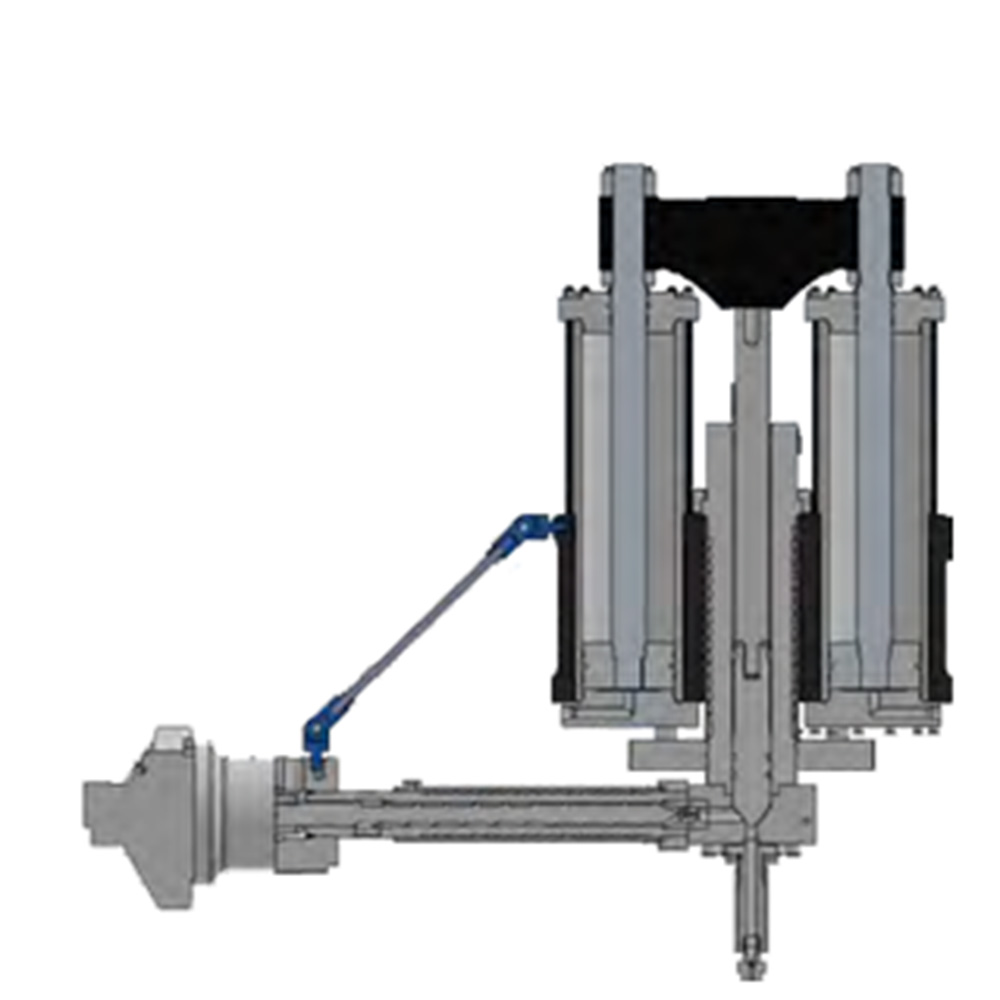

GW-RL Series Vertical Rubber Injection Machine are the most hot-selling & widely used GOWIN Rubber Injection Molding Machine models. The machines are equipped with VERTICAL CLAMPING SYSTEM & F.I.L.O. VERTICAL INJECTION SYSTEM, suitable for most rubber molded products in the fields of automobile, energy, railway transportation, industry, medical care and household appliances etc. And the Rubber Molding Machine is suitable for various of rubber compounds such as NR, NBR, EPDM, SBR, HNBR, FKM, SILICONE, ACM, AEM, etc.

The Rubber Molding Machine greatly improves production efficiency and reduces labor costs compared to traditional compression presses. It is an idea of Rubber Moulding Machine Models involving automation / semi-automation rubber molding. Also, the Rubber Machine is available for HOT RUNNER MOLD & COLD RUNNER BLOCK SYSTEM MOLD (optional solutions for CRB mold).

We GOWIN are expert for rubber machinery & rubber moulding solutions. Do not hesitate to contact us.

GW-RL Main Specification

|

Model |

GW-R120L |

GW-R160L |

GW-R250L |

GW-R300L |

GW-R350L |

GW-R400L |

|||||

|

Clamping Force(KN) |

1200 |

1600 |

2500 |

3000 |

3500 |

4000 |

|||||

|

Mold Open Stroke(mm) |

450 |

500 |

500 |

500 |

500 |

600 |

|||||

|

Platen Size(mm) |

430×500 |

500×500 |

560×630 |

600×700/600×800 |

700×800 |

700×800 |

|||||

|

Injection Volume(c.c) |

1000 |

1000 |

1000 |

2000 |

3000 |

3000 |

5000 |

3000 |

5000 |

5000 |

8000 |

|

Injection Force(bar) |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

| Model | GW-R550L | GW-R650L | GW-R800L | GW-R1200L | ||||

| Clamping Force(KN) | 5500 | 6500 | 8000 | 12000 | ||||

| Mold Open Stroke(mm) | 600 | 700 | 700 | 800 | ||||

| Platen Size(mm) | 850×1000 | 950×1000 | 950×1000 | 1200×1300 | ||||

| Injection Volume(c.c) | 5000 | 8000 | 5000 | 8000 | 8000 | 12000 | 12000 | 15000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

Packing & Shipping

|

Container |

GW-R120L |

GW-R160L |

GW-R250L |

GW-R300L |

GW-R400L |

|

20GP |

1 unit |

1 unit |

1 unit |

– |

- |

|

40HQ |

3 units |

3 units |

2 units |

2 units |

2 units |

|

Packing |

Package 1: Rubber Injection Machine Main Body |

||||

|

Package 2: Rubber Injection Machine Injection Unit |

|||||

|

Container |

GW-R550L |

GW-R650L |

GW-R800L |

GW-R1200L |

|

20GP |

– |

– |

– |

1 unit (one 40HQ + one 20GP) |

|

40HQ |

1 unit |

1 unit |

1 unit |

|

|

Packing |

Package 1: Vertical Rubber Injection Moulding Machine Main Body |

|||

|

Package 2: Vertical Rubber Injection Moulding Machine Injection Unit |

||||

Main Features

● Fixed-cylinder Vertical Injection

● High-pressure & High-precision Injection

● Modular-design & Multiple-combinations Solutions

● Low- bed & Optimized Structure

● Humanized Operating System

● High-efficiency & High-stability Hydraulic System

Injection System

● F.I.L.O. Injection System, low rubber feeding height.

● Two-Fixed Cylinder for injection, steady injection and high injection accuracy & stability

● Injection Unit center of gravity in bottom which lead to more steady operation.

● Excellent Oil Cooling System for SCREW & BARREL ensuring WHOLE RUBBER CHANCEL under accuracy temperature control to get better fluency of rubber compound.

● Injection Unit available to move up & down, more convenient for daily operation and maintenance.

Our High-Performance Rubber Making Machines for Precision and Efficiency are the epitome of technological innovation in the rubber manufacturing industry. Engineered with the latest advancements, these machines are designed to handle a wide variety of rubber materials with utmost precision. The state-of-the-art control systems ensure accurate temperature, pressure, and speed regulation, allowing for the production of rubber products with consistent quality and minimal defects.

Equipped with high-quality molds and advanced extrusion mechanisms, they can create complex rubber shapes and profiles with ease. The robust construction and durable components guarantee long-term reliability and minimal downtime, maximizing production output. Whether it’s for automotive rubber parts, industrial seals, or consumer rubber goods, our machines offer the flexibility and performance required to meet diverse market demands. With enhanced energy efficiency features, they not only reduce operational costs but also contribute to a more sustainable manufacturing process. Invest in our High-Performance Rubber Making Machines and take your rubber production to new heights of precision and efficiency.