We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate within our success for Discount Price Minimum Order Rubber Injection Molding Machine Baby Toys Making Machine for Liquid Silicone, We welcome consumers, business enterprise associations and friends from all elements of your world to get in touch with us and look for cooperation for mutual rewards.

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate within our success for China Baby Toys Maiking and Liquid Silicone Machine, In order to carry out our goal of “customer first and mutual benefit” in the cooperation, we establish a professional engineering team and a sales team to supply the best service to satisfy our customers’ requirements. Welcome you to cooperate with us and join us. We are your best choice.

Description

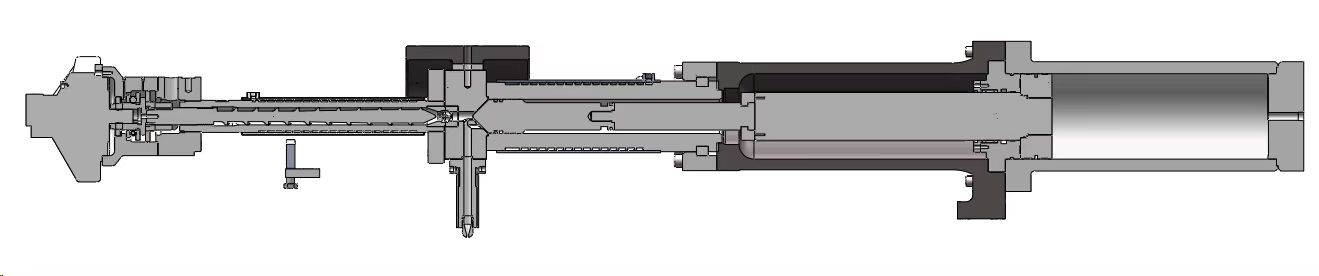

The GW-SL Series Rubber Injection Molding Machine with VERTICAL CLAMPING SYSTEM & F.I.L.O. Angle-Type INJECTION SYSTEM is one of the MOST POPULAR Rubber Molding Machine in the market. The Moulding Press Single-Fixed-Cylinder Injection Unit, horizontally mounting on the top platen which reduces overall rubber Press height a lot. This rubber press model is suitable for customers who have limited-height workshops.

Also, the Rubber Molding Machine is suitable for most rubber molded products in the fields of automobile, energy, railway transportation, industry, medical care and household appliances, etc. The Molding Machine is suitable for various rubber compounds such as NR, NBR, EPDM, SBR, HNBR, FKM, SILICONE, ACM, AEM, etc.

The Rubber Injection Moulding Machine greatly improves production efficiency and reduces labor costs compared with traditional compression press.

GW-SL Main Specification

| Model | GW-S120L | GW-S160L | GW-S250L | GW-S300L | GW-S400L | ||||

| Clamping Force(KN) | 1200 | 1600 | 2500 | 3000 | 4000 | ||||

| Mold Open Stroke(mm) | 450 | 500 | 500 | 500 | 600 | ||||

| Platen Size(mm) | 430×500 | 500×500 | 560×630 | 600×700/600×800 | 700×800 | ||||

| Injection Volume(c.c) | 1000 | 1000 | 1000 | 2000 | 3000 | 3000 | 5000 | 5000 | 8000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

| Model | GW-S550L | GW-S650L | GW-S800L | GW-S1200L | ||||

| Clamping Force(KN) | 5500 | 6500 | 8000 | 12000 | ||||

| Mold Open Stroke(mm) | 600 | 700 | 700 | 800 | ||||

| Platen Size(mm) | 850×1000 | 950×1000 | 950×1000 | 1200×1300 | ||||

| Injection Volume(c.c) | 5000 | 8000 | 5000 | 8000 | 8000 | 12000 | 12000 | 15000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

Packing & Shipping

|

Container |

GW-S120L |

GW-S160L |

GW-S250L |

GW-S300L |

GW-S400L |

|

20GP |

1 unit |

1 unit |

1 unit |

– |

- |

|

40HQ |

3 units |

3 units |

2 units |

2 units |

2 units |

|

Packing |

Package 1: Rubber Injection Moulding Machine Main Body; |

||||

|

Package 2: Rubber Injection Moulding Machine Injection Unit |

|||||

|

Container |

GW-S550L |

GW-S650L |

GW-S800L |

GW-S1200L |

|

20GP |

– |

– |

– |

1 unit (one 40HQ + one 20GP) |

|

40HQ |

1 unit |

1 unit |

1 unit |

|

|

Packing |

Package 1: Injection Moulding Machine Main Body; |

|||

|

Package 2: Injection Moulding Machine Injection Unit |

||||

Main Features

● Vertical Clamping Unit & Angle-type Injection Unit

● High-pressure & High-precision Injection

● Modular-design & Multiple-combinations Solution

● Low Overall Height

● Humanized Operating System

● High-efficiency & High-stability Hydraulic System

Injection System

● 1. F.I.L.O. Injection System, low rubber feeding height.

● 2. Single-Fixed-Cylinder Injection Unit, Horizontally Mounting On The Top Platen.

● 3. Steady Injection and High Injection accuracy & stability

● 4. Excellent Oil Cooling System for SCREW & BARREL ensuring good performance of rubber compound.

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate within our success for Discount Price Minimum Order Rubber Injection Molding Machine Baby Toys Making Machine for Liquid Silicone, We welcome consumers, business enterprise associations and friends from all elements of your world to get in touch with us and look for cooperation for mutual rewards.

Discount Price China Baby Toys Maiking and Liquid Silicone Machine, In order to carry out our goal of “customer first and mutual benefit” in the cooperation, we establish a professional engineering team and a sales team to supply the best service to satisfy our customers’ requirements. Welcome you to cooperate with us and join us. We are your best choice.

-

ODM Manufacturer Vertical Rubber Injection Mold...

-

Renewable Design for Momu All New Vertical Rubb...

-

Factory made hot-sale Vacuum Compression Moldin...

-

Top Quality Tyre Recycling System / New High Qu...

-

2019 New Style OEM/ODM Rubber Damper Shock Abso...

-

ODM Polyurethane High Pressure PU Foam Machiner...