We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Dealers of Silicone Automatic Speed Pneumatic Vertical manufacturers Injection Molding Machine, If you are interested in almost any of our goods, make sure you feel no cost to call us for more aspects. We hope to cooperate with additional mates from all over the earth.

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Silicone Injection Molding Machine Logo and Injection PU Molding Machine PU, Our company always concentrate on the development of the international market. We have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

Description

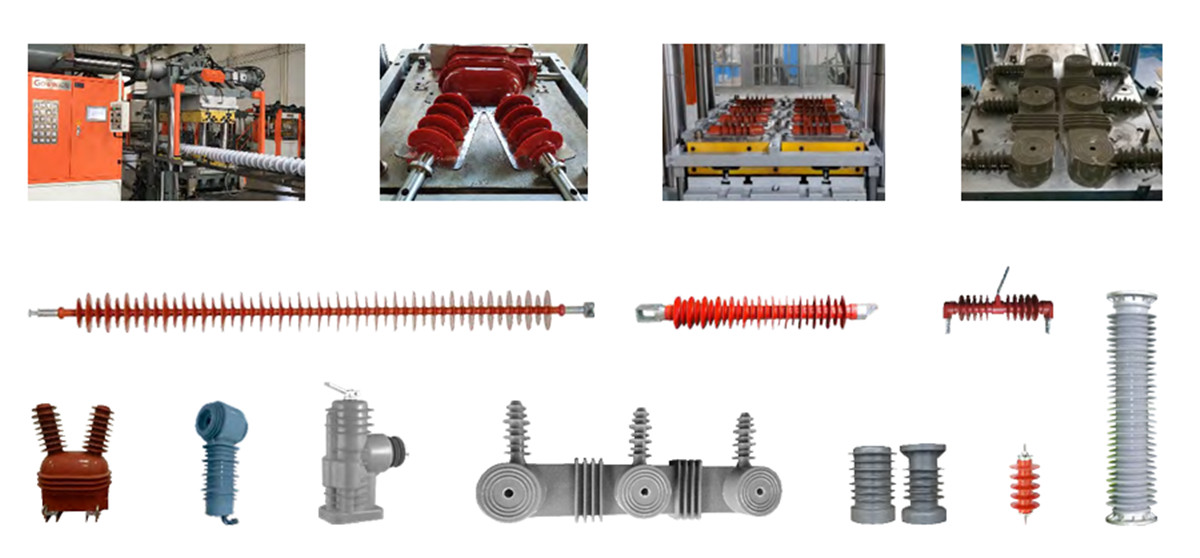

GOWIN GW-SL Series Solid Silicone Injection Moulding Machine for Energy Industry is one of the most hot-selling & star model among GOWIN Rubber Injection Machine models. The silicone rubber molding machines are equipped with VERTICAL CLAMPING SYSTEM & F.I.L.O. HORIZONTAL INJECTION SYSTEM & Large Capacity Silicone Stuffer, which are special designed models for Polymer Insulator, Arrester, Cable Accessories etc. It is ideal model for large component of silicone rubber mouldings.

The Insulator Making Machine is greatly improving production efficiency and reducing labor costs. The Silicone Injection Machine are available for HOT RUNNER MOLD & COLD RUNNER BLOCK SYSTEM MOLD.

With over 16 years sufficient experience in the field of power transmission & distribution, GOWIN has exported many Silicone Insulator Molding Machines to many countries such Korea, Russia, India, Egypt, Ukraine, Indonesia, Thailand, Malaysia, Vietnam etc. GOWIN are providing turn-key solutions for insulator molding including factory layout suggestion, insulator moulding machine, Insulator Mold, Crimping Machine, Tension Testing Machine, Electrical Testing Equipment, Rubber Material, Production Training etc.

Solid Silicone Injection Series Main Specification

|

Model |

GW-S160L |

GW-S250L |

GW-S300L |

GW-S360L |

GW-S400L |

GW-S550L |

|

|

Clamping Force(KN) |

1600 |

2500 |

3000 |

3600 |

4000 |

5500 |

|

|

Mold Open Stroke(mm) |

500 |

500 |

500 |

500 |

600 |

600 |

|

|

Platen Size(mm) |

500×630 |

600×800 |

600×800/630×1000 |

630×1300 |

750×800 |

630×1700/630×1500/800×1000 |

|

|

Injection Volume(c.c) |

3000 |

3000 |

5000 |

6000 |

6000/8000 |

6000/8000 |

13000/15000 |

|

Injection Force(bar) |

1375 |

1375 |

1375 |

1260 |

1260 |

1260 |

1260 |

|

Model |

GW-S650L |

GW-S1000L |

GW-S1100L |

GW-S1800L |

|

Clamping Force(KN) |

6500 |

10000 |

11000 |

18000 |

|

Mold Open Stroke(mm) |

700 |

800 |

700 |

1200 |

|

Platen Size(mm) |

800×1700/950×1700 |

1000×1800 |

800×2600 |

1000×2600 |

|

Injection Volume(c.c) |

15000/20000/25000 |

25000/32000 |

25000/32000 |

50000/60000 |

|

Injection Force(bar) |

1260 |

1260 |

1260 |

1260 |

Packing & Shipping

|

Container |

GW-S160L |

GW-S250L |

GW-S300L |

GW-S360L |

GW- S400L |

|

20GP |

1 unit |

– |

– |

– |

- |

|

40HQ |

3 units |

2 units |

2 units |

2 units |

2 units |

|

Packing |

Package 1: Rubber Injection Moulding Machine Main Body |

||||

|

Package 2: Rubber Injection Moulding Machine Silicone Stuffer |

|||||

|

Container |

GW- S550L |

GW- S650L |

GW- S1000L |

GW-S1100L |

GW-S1800L |

|

20GP |

– |

– |

1 unit (two 40HQ) |

1 unit (two 40HQ) |

1 unit (two 40HQ + one 20GP) |

|

40HQ |

1 unit |

1 unit |

|||

|

Packing |

Package 1: Rubber Injection Molding Machine Main Body; |

||||

|

Package 2: Rubber Injection Molding Machine Injection Unit; |

|||||

|

Package 3: Rubber Injection Molding Machine Guarding |

|||||

Main Features

● Specialized Design for Solid Silicone Product Molding in Energy Industry, such as for Polymer Insulator, Polymer Fuse Cut-out, Polymer Transformer etc.

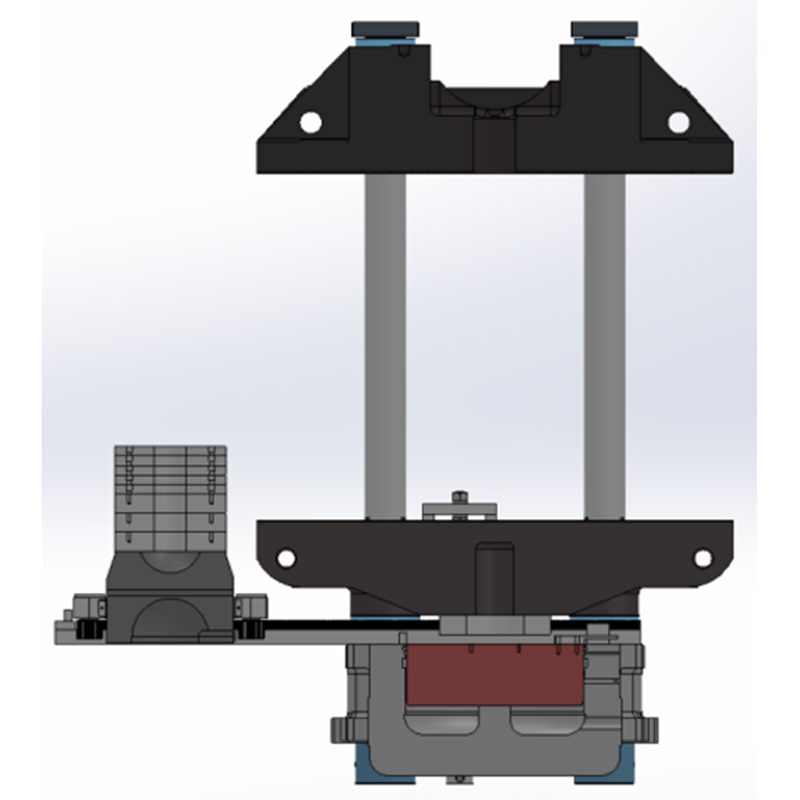

● Specialized Designed Angle-type Injection System for Solid Silicone.

● Reasonable Machine Layout, Convenient for Operation in All Access.

● Strong Enough Mechanical Structure to Ensure Stable Molding Quality

● Large Enough Silicone Stuffer On Floor.

Injection System

● GOWIN Patent “Three-Step Mold Close System” (for big Ton Machine Models).

● Low Operation Height, Convenient & Safe.

● Strong Structure, Movement Steady.

Silicone Automatic Speed Pneumatic Vertical Manufacturers Injection Molding Machine dealers play a crucial role in the silicone product manufacturing industry. These dealers are the bridge connecting the manufacturers with the end-users who have a diverse range of needs for silicone products.

The Silicone Automatic Speed Pneumatic Vertical Injection Molding Machine is a sophisticated piece of equipment. It is designed to handle the unique properties of silicone materials with precision. The automatic speed control feature allows for efficient and consistent production, ensuring that each molded part meets the required quality standards. The pneumatic vertical design offers advantages in terms of space utilization and ease of operation. It enables quick and smooth mold closing and opening, reducing production cycle times.

Dealers of such machines are responsible for providing comprehensive services. They not only offer a variety of machine models with different specifications to suit different production scales but also provide technical support and after-sales service. They help customers understand the machine’s functions and operation procedures, train the operators, and ensure that any technical issues are promptly resolved. This way, they contribute to the successful operation and productivity enhancement of silicone product manufacturing enterprises, facilitating the creation of high-quality silicone products used in various fields such as automotive, medical, and consumer goods.