It adheres on the tenet “Honest, industrious, enterprising, innovative” to acquire new solutions regularly. It regards shoppers, success as its very own success. Let us establish prosperous future hand in hand for China New Product Prototype Mold Silicone Rubber Mold PU Plastic Precision Injection Molding Service, In a word, when you choose us, you choose a ideal life. Welcome to go to our manufacturing unit and welcome your get! For further more inquiries, remember to usually do not be reluctant to get in touch with us.

It adheres on the tenet “Honest, industrious, enterprising, innovative” to acquire new solutions regularly. It regards shoppers, success as its very own success. Let us establish prosperous future hand in hand for Silicone Rubber Molds and Injection Molding Parts, We have 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export products to other countries. We expect to cooperate with you to develop a larger market.

Main Features

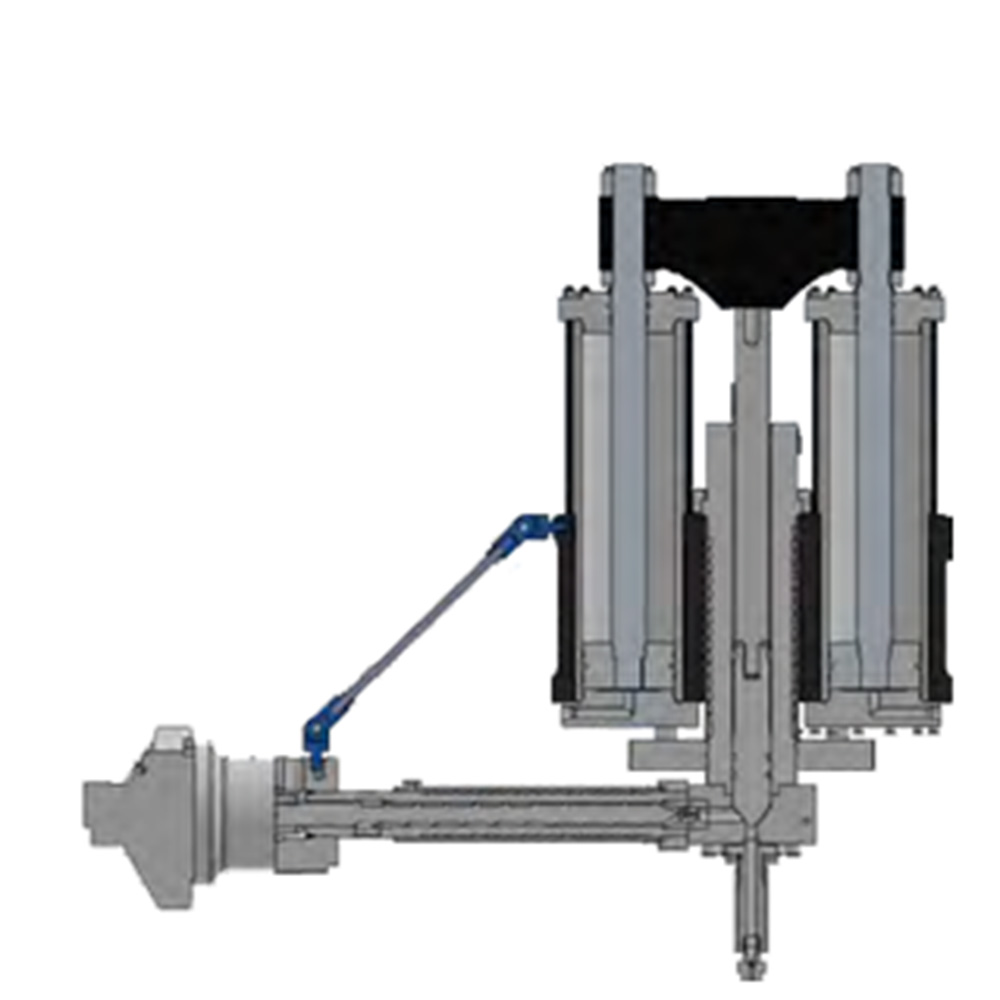

GW-RL Series Vertical Rubber Injection Machine are the most hot-selling & widely used GOWIN Rubber Injection Molding Machine models. The machines are equipped with VERTICAL CLAMPING SYSTEM & F.I.L.O. VERTICAL INJECTION SYSTEM, suitable for most rubber molded products in the fields of automobile, energy, railway transportation, industry, medical care and household appliances etc. And the Rubber Molding Machine is suitable for various of rubber compounds such as NR, NBR, EPDM, SBR, HNBR, FKM, SILICONE, ACM, AEM, etc.

The Rubber Molding Machine greatly improves production efficiency and reduces labor costs compared to traditional compression presses. It is an idea of Rubber Moulding Machine Models involving automation / semi-automation rubber molding. Also, the Rubber Machine is available for HOT RUNNER MOLD & COLD RUNNER BLOCK SYSTEM MOLD (optional solutions for CRB mold).

We GOWIN are expert for rubber machinery & rubber moulding solutions. Do not hesitate to contact us.

GW-RL Main Specification

|

Model |

GW-R120L |

GW-R160L |

GW-R250L |

GW-R300L |

GW-R350L |

GW-R400L |

|||||

|

Clamping Force(KN) |

1200 |

1600 |

2500 |

3000 |

3500 |

4000 |

|||||

|

Mold Open Stroke(mm) |

450 |

500 |

500 |

500 |

500 |

600 |

|||||

|

Platen Size(mm) |

430×500 |

500×500 |

560×630 |

600×700/600×800 |

700×800 |

700×800 |

|||||

|

Injection Volume(c.c) |

1000 |

1000 |

1000 |

2000 |

3000 |

3000 |

5000 |

3000 |

5000 |

5000 |

8000 |

|

Injection Force(bar) |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

2150 |

| Model | GW-R550L | GW-R650L | GW-R800L | GW-R1200L | ||||

| Clamping Force(KN) | 5500 | 6500 | 8000 | 12000 | ||||

| Mold Open Stroke(mm) | 600 | 700 | 700 | 800 | ||||

| Platen Size(mm) | 850×1000 | 950×1000 | 950×1000 | 1200×1300 | ||||

| Injection Volume(c.c) | 5000 | 8000 | 5000 | 8000 | 8000 | 12000 | 12000 | 15000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

Packing & Shipping

|

Container |

GW-R120L |

GW-R160L |

GW-R250L |

GW-R300L |

GW-R400L |

|

20GP |

1 unit |

1 unit |

1 unit |

– |

- |

|

40HQ |

3 units |

3 units |

2 units |

2 units |

2 units |

|

Packing |

Package 1: Rubber Injection Machine Main Body |

||||

|

Package 2: Rubber Injection Machine Injection Unit |

|||||

|

Container |

GW-R550L |

GW-R650L |

GW-R800L |

GW-R1200L |

|

20GP |

– |

– |

– |

1 unit (one 40HQ + one 20GP) |

|

40HQ |

1 unit |

1 unit |

1 unit |

|

|

Packing |

Package 1: Vertical Rubber Injection Moulding Machine Main Body |

|||

|

Package 2: Vertical Rubber Injection Moulding Machine Injection Unit |

||||

Main Features

● Fixed-cylinder Vertical Injection

● High-pressure & High-precision Injection

● Modular-design & Multiple-combinations Solutions

● Low- bed & Optimized Structure

● Humanized Operating System

● High-efficiency & High-stability Hydraulic System

Injection System

● F.I.L.O. Injection System, low rubber feeding height.

● Two-Fixed Cylinder for injection, steady injection and high injection accuracy & stability

● Injection Unit center of gravity in bottom which lead to more steady operation.

● Excellent Oil Cooling System for SCREW & BARREL ensuring WHOLE RUBBER CHANCEL under accuracy temperature control to get better fluency of rubber compound.

● Injection Unit available to move up & down, more convenient for daily operation and maintenance.

It adheres on the tenet “Honest, industrious, enterprising, innovative” to acquire new solutions regularly. It regards shoppers, success as its very own success. Let us establish prosperous future hand in hand for China New Product Prototype Mold Silicone Rubber Mold PU Plastic Precision Injection Molding Service, In a word, when you choose us, you choose a ideal life. Welcome to go to our manufacturing unit and welcome your get! For further more inquiries, remember to usually do not be reluctant to get in touch with us.

China New Product Silicone Rubber Molds and Injection Molding Parts, We have 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export products to other countries. We expect to cooperate with you to develop a larger market.