Bear “Customer first, High quality first” in mind, we perform closely with our consumers and provide them with efficient and experienced services for Big discounting Lab Hydraulic Vulcanizing Heat Mould Press Thermoforming Machine for Rubber and Plastic 10% off, If you are interested in almost any of our goods, make sure you feel no cost to call us for more aspects. We hope to cooperate with additional mates from all over the earth.

Bear “Customer first, High quality first” in mind, we perform closely with our consumers and provide them with efficient and experienced services for China Vulcanizing Press Machine and Heat Press Machine, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We are able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and products. For anyone who is interested in our company and items, please make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are going to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please really feel no cost to speak to us for enterprise. nd we believe we are going to share the most effective trading practical experience with all our merchants.

Description

The GW-SL Series Rubber Injection Molding Machine with VERTICAL CLAMPING SYSTEM & F.I.L.O. Angle-Type INJECTION SYSTEM is one of the MOST POPULAR Rubber Molding Machine in the market. The Moulding Press Single-Fixed-Cylinder Injection Unit, horizontally mounting on the top platen which reduces overall rubber Press height a lot. This rubber press model is suitable for customers who have limited-height workshops.

Also, the Rubber Molding Machine is suitable for most rubber molded products in the fields of automobile, energy, railway transportation, industry, medical care and household appliances, etc. The Molding Machine is suitable for various rubber compounds such as NR, NBR, EPDM, SBR, HNBR, FKM, SILICONE, ACM, AEM, etc.

The Rubber Injection Moulding Machine greatly improves production efficiency and reduces labor costs compared with traditional compression press.

GW-SL Main Specification

| Model | GW-S120L | GW-S160L | GW-S250L | GW-S300L | GW-S400L | ||||

| Clamping Force(KN) | 1200 | 1600 | 2500 | 3000 | 4000 | ||||

| Mold Open Stroke(mm) | 450 | 500 | 500 | 500 | 600 | ||||

| Platen Size(mm) | 430×500 | 500×500 | 560×630 | 600×700/600×800 | 700×800 | ||||

| Injection Volume(c.c) | 1000 | 1000 | 1000 | 2000 | 3000 | 3000 | 5000 | 5000 | 8000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

| Model | GW-S550L | GW-S650L | GW-S800L | GW-S1200L | ||||

| Clamping Force(KN) | 5500 | 6500 | 8000 | 12000 | ||||

| Mold Open Stroke(mm) | 600 | 700 | 700 | 800 | ||||

| Platen Size(mm) | 850×1000 | 950×1000 | 950×1000 | 1200×1300 | ||||

| Injection Volume(c.c) | 5000 | 8000 | 5000 | 8000 | 8000 | 12000 | 12000 | 15000 |

| Injection Force(bar) | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 | 2150 |

Packing & Shipping

|

Container |

GW-S120L |

GW-S160L |

GW-S250L |

GW-S300L |

GW-S400L |

|

20GP |

1 unit |

1 unit |

1 unit |

– |

- |

|

40HQ |

3 units |

3 units |

2 units |

2 units |

2 units |

|

Packing |

Package 1: Rubber Injection Moulding Machine Main Body; |

||||

|

Package 2: Rubber Injection Moulding Machine Injection Unit |

|||||

|

Container |

GW-S550L |

GW-S650L |

GW-S800L |

GW-S1200L |

|

20GP |

– |

– |

– |

1 unit (one 40HQ + one 20GP) |

|

40HQ |

1 unit |

1 unit |

1 unit |

|

|

Packing |

Package 1: Injection Moulding Machine Main Body; |

|||

|

Package 2: Injection Moulding Machine Injection Unit |

||||

Main Features

● Vertical Clamping Unit & Angle-type Injection Unit

● High-pressure & High-precision Injection

● Modular-design & Multiple-combinations Solution

● Low Overall Height

● Humanized Operating System

● High-efficiency & High-stability Hydraulic System

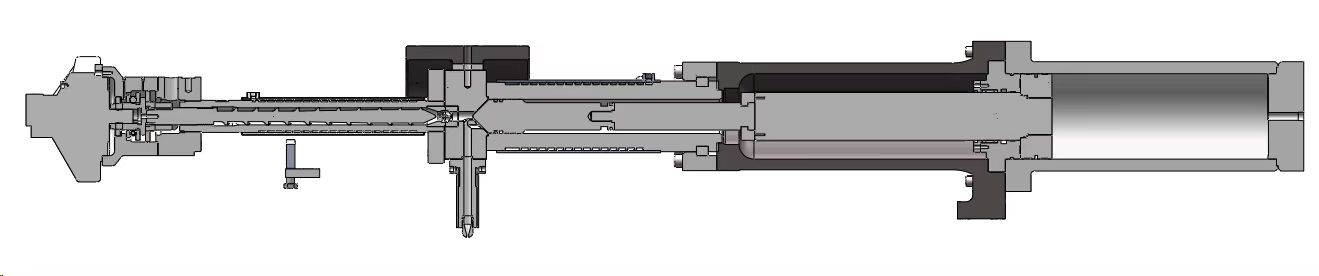

Injection System

● 1. F.I.L.O. Injection System, low rubber feeding height.

● 2. Single-Fixed-Cylinder Injection Unit, Horizontally Mounting On The Top Platen.

● 3. Steady Injection and High Injection accuracy & stability

● 4. Excellent Oil Cooling System for SCREW & BARREL ensuring good performance of rubber compound.

Bear “Customer first, High quality first” in mind, we perform closely with our consumers and provide them with efficient and experienced services for Big discounting Lab Hydraulic Vulcanizing Heat Mould Press Thermoforming Machine for Rubber and Plastic 10% off, If you are interested in almost any of our goods, make sure you feel no cost to call us for more aspects. We hope to cooperate with additional mates from all over the earth.

Big discounting China Vulcanizing Press Machine and Heat Press Machine, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We are able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and products. For anyone who is interested in our company and items, please make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are going to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please really feel no cost to speak to us for enterprise. nd we believe we are going to share the most effective trading practical experience with all our merchants.

-

Factory Directly supply Vertical Type Automatic...

-

Automatic Double Shaft Shredder Plastic Sheet B...

-

ODM Manufacturer Vertical Rubber Injection Mold...

-

Supply OEM Factory Customize Vertical Automatic...

-

OEM/ODM Factory Rubber O-Ring Seal Ring Assembl...

-

Factory made hot-sale Vacuum Compression Moldin...